Fluid makers need to respond quickly to the changing face of personal mobility and drivetrains.

The modern era of personal mobility comprises a variety of drivetrain options, with pure battery-powered electric vehicles the most prominent among them in terms of grabbing headlines, if not sales. This marks a critical turn of fortunes for lubricant manufacturers working hard to adjust their product portfolios, tweak capacities and develop formulations for the fluids needed to maintain optimum performance of new types of vehicles.

Global vehicle production is expected to approach 120 million units per year by 2030, according to IHS Markit. The London-based consultancy predicts that half of those vehicles will be in some way electrified – four-fifths by start-stop systems or some other mild hybrid technology, the rest being plug-in hybrids or pure BEVs.

A Shell official speaking at a recent lubricant industry conference said these changes will have big impacts on the provision of motor fuels and automotive lubes.

“The energy systems of the future are going to look very different, and new mobility options, such as battery electric vehicles, will turn the future of the refining and lubricants industry upside down,” Gunnar Meister, principal technologist of Shell’s base oil team lead, told delegates at the ACI European Base Oils & Lubricants conference.

|

“E-fluids are a key growth area because electric vehicles require a wide range of lubricants, greases and process oils.”

— Gunnar Meister, Shell

|

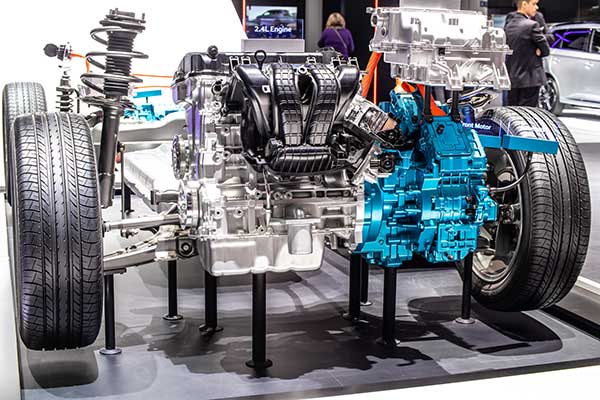

For example, vehicles running solely on electricity, such as BEVs or those powered by fuel cells, will not need engine oils, by far the largest category of lubricants by volume. Hybrids will, however, because along with their electric motor they contain an internal combustion engine that also generates electricity to recharge the battery.

Shell’s focus now is at what have become known as e-fluids, or lubricating products designed for electric-powered vehicles.

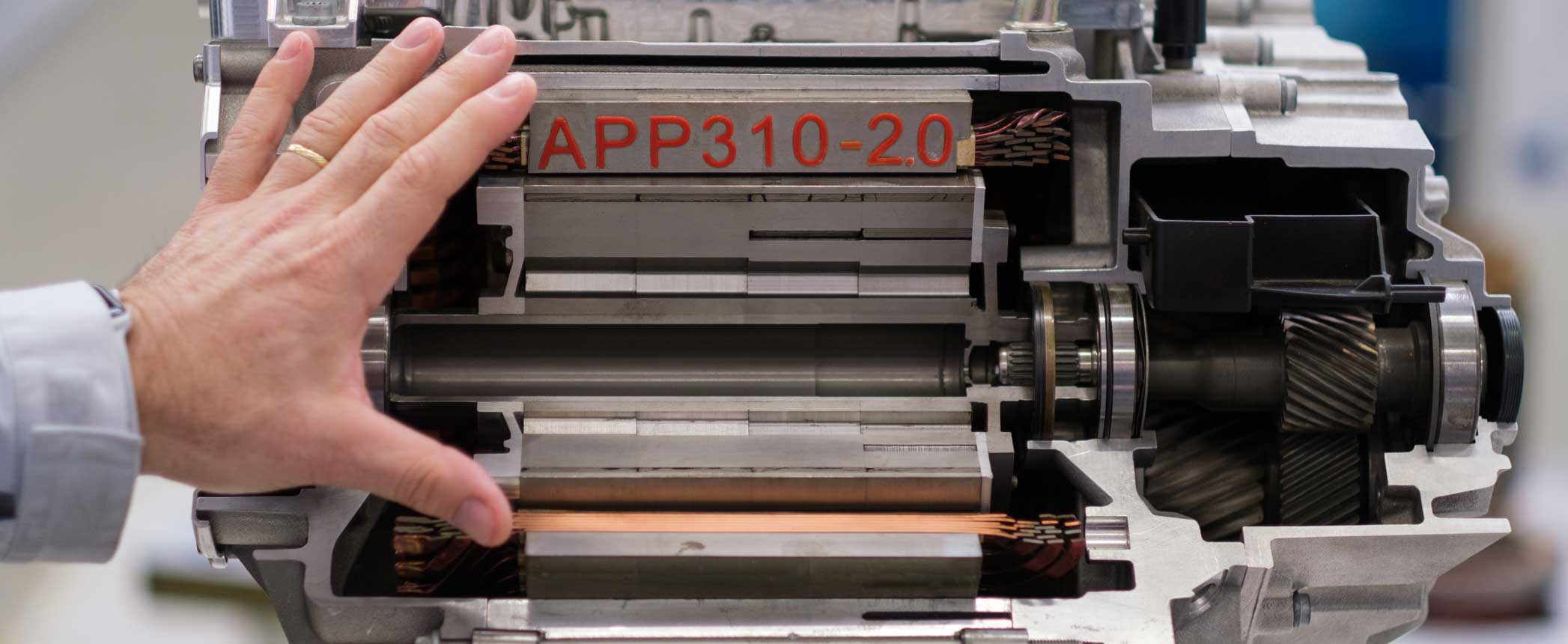

“E-fluids are a key growth area because electric vehicles require a wide range of lubricants, greases and process oils,” Meister said. For example, he said, coolants are needed to help reduce heat generated by car batteries, e-motors, inverters – which convert the battery’s electricity from direct to alternating current – and the copper wire that is extensively wound around the motor’s core.

These requirements are an area of particular interest for lubricant marketers. OEMs have actually tried a variety of ways to cool e-motors, including forced air, water jackets and oil spray, as well as immersion in cooling fluid. The latter has the greatest potential for heat removal, Meister said, and therefore enables motors with greater power density.

There are likewise multiple ways of cooling batteries, including coolant immersion and use of cold plates. Again, immersion has the potential to remove more heat, enabling greater power density and extending battery life.

“This would save weight, materials and cost, as well as help make hardware to work more efficiently,” Meister said.

Greases are needed to lubricate the bearings in e-motors as well as wheels and steering systems.

EVs use transmission fluids for reduction gear and differential lubrication, and Shell believes specific solutions will be needed for the plug-in hybrid transmission fluids and engine oils. EVs even spur the need for process oils used in the production of battery membranes, Meister said.

Electrification will have a wide variety of impacts on automotive lubricants and the equipment they are supposed to protect, Meister said. Frequent start-stops could compromise the durability of engine components. Extensive operation of e-motors could lead to higher levels of fuel and water in internal combustion engine oils in PHEVs, as well as increased risk of fretting. Hybridization could also affect drain intervals

EV transmissions operate at higher speeds than those in ICEs, which could cause higher levels of aeration and require greater control of foaming. EV transmission fluids also must behave electrical characteristics compatible with exposed electrical components and conductors, including sensor contacts.

Electrification significantly alters the performance needs of automotive greases, which are key to minimizing noise of high-speed bearings. Greases also have to have compatibility with the transmission oils and be tailor made for maximum efficiency, Meister said.

Sorry, a technical error occurred and we were unable to log you into your account. We have emailed the problem to our team, and they are looking into the matter. You can reach us at cs@lubesngreases.com.

Click here link to homepage