The global fleet of hybrids could grow faster than battery electric vehicles as industry experts forecast that powertrain production in the short term will be a mix of many propulsion systems, while this in turn could have a profound effect on the lubricants industry.

This mix includes conventional internal combustion engine-only vehicles with various degrees of hybridization and full electric and fuel-cell electric vehicles, according to Infineum, a lubricant additive maker.

“Taking a holistic approach to future hybrid powertrains, with multiple innovation options to improve and optimize their efficiencies, including the use of larger volumes of sustainable low carbon fuels, may well present a viable challenge to the case for the BEVs,” the company said in a recent publication.

>Read more about EV powertrain fluids here.

Projections for this decade vary widely on the uptake of the various electrification architectures, but show rapid rises in the production of both EV and the main hybrid powertrains by 2028, Infineum said.

In its powertrain forecast published in August 2021, IHS Markit, a London-based consultancy, found that annual combined production of BEVs and hybrids, which include such systems as start-stop micro hybrid EVs, mild hybrid EVs, full hybrid EVs and plug-in-hybrids, would comprise 60% of the total by 2028.

The start-stop micro hybrid category may shrink even further if the adoption of 48-volt powertrain architectures expands the mild-hybrid segment at the expense of this category, Infineum said. The ICE and start-stop hybrid systems are moving from 12V to 48V+12V and higher voltages for BEVs as a means of achieving high range, power and efficiency and faster charging times.

The consultancy thinks that by 2028 BEV production would reach about 27 million units annually, while the production of vehicles with different hybrid systems would reach 35 million units.

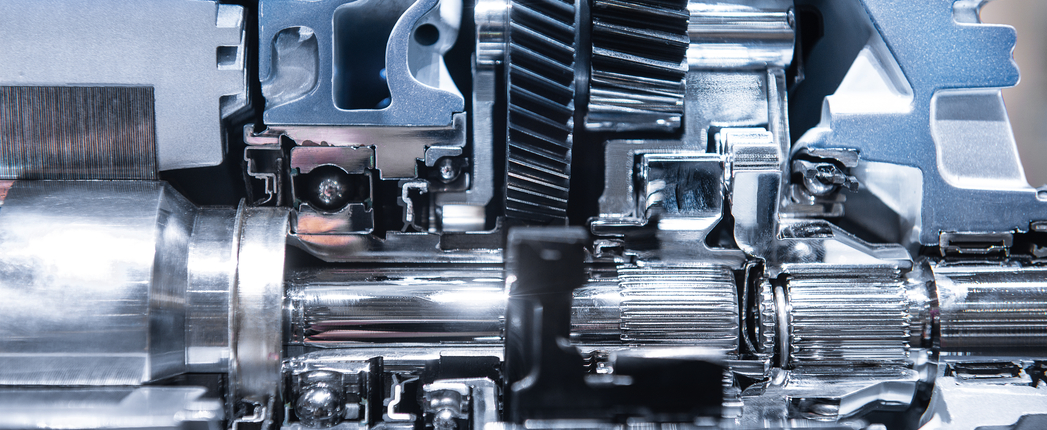

To stress the importance of synergy between the electric motors and improved ICEs achieved in the hybrid propulsion systems, some experts have dubbed these engines as e-ICEs.

“This new class of e-ICE technology increasingly creates a need for lubricants specifically designed to protect the hardware, including new after-treatment systems, and to handle the special hybrid operating duty cycles,” Ivan Portnyagin, technical sales account manager for lubes at Infineum’s Moscow office, told RPI’s Lubricant Week online conference in October.

In addition, standardized lubricant test methods will be required to meet the needs of the expanding e-ICE powertrain segment, he said.

Infineum found that manufacturers are developing tailored e-fluids “because the designs are becoming more demanding on fluids and increasing installations justify bespoke fluids.”

For its full hybrid electric Prius, Toyota developed WS automatic transmission fluids. For its full hybrid electric Passat, Volkswagen developed a dual clutch transmission fluid called EG 52529. For its Model 3, Tesla developed automatic transmission fluids called Tesla High Performance.

Along with transmission performance and safety, the properties of e-fluids – like heat transfer to cool windings, material compatibility for such metals and plastics as cooper and resin and electrical insulation – must be considered. The higher voltage would require new materials for high-voltage-rated components and dedicated e-fluids, Portnyagin said.

High temperatures can lead to motor performance loss and demagnetization, he said. Winding heads and magnetic rotors may be subject to localized hot spots at peak loads.

“Direct oil cooling is more efficient and less complex than water cooling jackets,” Portnyagin said, adding that oil cooling can allow for faster cooldown after peak e-motor operation with high efficiency and low flow rates.

He also said that e-fluids require optimum electrical properties to prevent any short circuit in high-voltage applications and new material compatibility challenges.

Infineum advises e-fluid formulators to focus on ultra-low viscosity for increased fuel economy and cooling. The additive maker said that it had already developed several e-fluid products for automatic, continuous variable and dual clutch transmissions, as well as dedicated hybrid and ultra-low BEV gear oils.

Portnyagin said the company’s new generation of e-fluid technology provides higher fuel efficiency, volume resistivity and frictional performance for wet clutches. Data gathered by Infineum found that more than 70% of the world’s on-road hybrid and electric vehicles use the company’s technology in dedicated lubricant and fluid products.

“This is an assessment made by our experts and it is based on the registrations of new automobiles in which this technology is applied all the way back in the late 1990s to up to year of 2020,” he said.

Sorry, a technical error occurred and we were unable to log you into your account. We have emailed the problem to our team, and they are looking into the matter. You can reach us at cs@lubesngreases.com.

Click here link to homepage