A life cycle assessment quantifies the environmental impacts of materials, products, systems and services. An LCA gathers data, aids decision-making and is typically structured to meet a specific goal, like making a lubricant package more sustainable or reducing the carbon footprint of an additive.

An LCA examines such things as potential toxicity, acidification or eutrophication, associated greenhouse gas emissions, embodied* and operational energy and water usage, waste generation and land clearing. This helps identify where impacts can be reduced and products and processes can be improved.

LCAs can also help organizations comply with mandatory emissions regulations or carry out Scope 3 greenhouse gas reporting; create cost-efficient automated benchmarks from existing data against which new assessments can be made; and improve transparency for internal and external stakeholders.

Focusing on products, the stages of an LCA can be separated into distinct phases:

- Extraction and collection of raw materials (referred to as the “cradle”)

- Processing, manufacturing

- Packaging, distribution

- Use

- Disposal and/or recycling (referred to as the “grave”)

Each phase has a number of inputs and outputs, like consuming a resource and producing waste or byproducts. Examples of inputs related to the lubricant industry might be:

- Raw materials – mineral oil raffinate, natural gas, esters, additives, plastics and metals for packaging

- Energy – power for refineries, blending heaters and facilities, fuel for transport vehicles and workforce travel

- Water – production process water, facilities usage

- Chemicals – acids, solvents, oleochemical feedstock

And outputs:

- Greenhouse gas emissions – operational facilities, product distribution, workforce transport

- Waste – chemical waste, discarded storage drums, facility solid waste, waste water

And outputs:

- Greenhouse gas emissions – operational facilities, product distribution, workforce transport

- Waste – chemical waste, discarded storage drums, facility solid waste, waste water

And outputs:

- Greenhouse gas emissions – operational facilities, product distribution, workforce transport

- Waste – chemical waste, discarded storage drums, facility solid waste, waste water

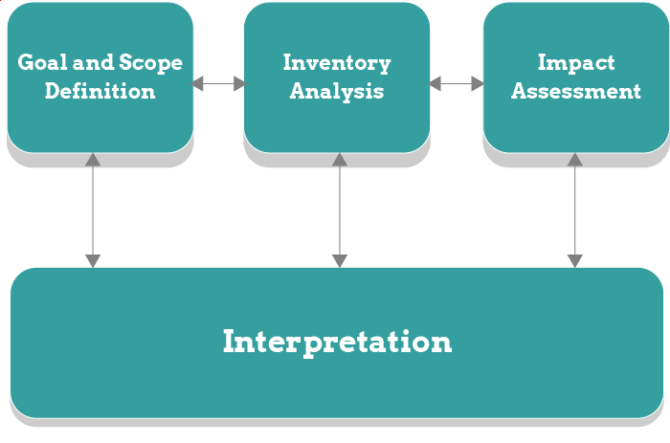

Gathering data from the numerous phases of a product’s life cycle and their various inputs and outputs make an LCA a complex and potentially expensive task, especially when a product portfolio is extensive. The process can be broken down into several stages.

- Inventory (LCI) – a protracted and painstaking process of collecting and compiling relevant data on the types and flows of raw materials, energy inputs, product life expectancy and outputs.

- Impact assessment (LCIA) – the evaluation and refining of data gathered in the LCI associated with identified inputs and outputs into a smaller number of impact categories. LCIA data turns LCI data into environmental impacts using characterization modeling. According to the Encyclopaedia of Energy, an LCIA consists of:

- Selecting the relevant impact categories

- Classification – assigning the elementary flows to the impact categories

- Characterization – modeling potential impacts using conversion factors to obtain an indicator for the impact category

- Normalization (optional) – expressing potential impacts relative to a reference

- Grouping – sorting or ranking impact indicators

- Weighting – relative weighting of impact categories, along with evaluation and reporting

- Interpretation – Analyzing the results to reach a set of conclusions that will assist in decision-making. According to the International Standards Organization’s ISO 14040, interpretation should include:

- Identification of significant issues based on the results of the LCI and LCIA

- Evaluation of the study, considering completeness, sensitivity and consistency checks

- Conclusions, limitations and recommendations

- Inventory (LCI) – a protracted and painstaking process of collecting and compiling relevant data on the types and flows of raw materials, energy inputs, product life expectancy and outputs.

- Impact assessment (LCIA) – the evaluation and refining of data gathered in the LCI associated with identified inputs and outputs into a smaller number of impact categories. LCIA data turns LCI data into environmental impacts using characterization modeling. According to the Encyclopaedia of Energy, an LCIA consists of:

- Selecting the relevant impact categories

- Classification – assigning the elementary flows to the impact categories

- Characterization – modeling potential impacts using conversion factors to obtain an indicator for the impact category

- Normalization (optional) – expressing potential impacts relative to a reference

- Grouping – sorting or ranking impact indicators

- Weighting – relative weighting of impact categories, along with evaluation and reporting

- Interpretation – Analyzing the results to reach a set of conclusions that will assist in decision-making. According to the International Standards Organization’s ISO 14040, interpretation should include:

- Identification of significant issues based on the results of the LCI and LCIA

- Evaluation of the study, considering completeness, sensitivity and consistency checks

- Conclusions, limitations and recommendations

- Selecting the relevant impact categories

- Classification – assigning the elementary flows to the impact categories

- Characterization – modeling potential impacts using conversion factors to obtain an indicator for the impact category

- Normalization (optional) – expressing potential impacts relative to a reference

- Grouping – sorting or ranking impact indicators

- Weighting – relative weighting of impact categories, along with evaluation and reporting

- Identification of significant issues based on the results of the LCI and LCIA

- Evaluation of the study, considering completeness, sensitivity and consistency checks

- Conclusions, limitations and recommendations

Two familiar phrases associated with LCAs are “cradle to gate” and “cradle to grave.” They both define the scope of the LCA by the point at which measurement ends.

In the first case, cradle to gate, it ends at the point of distribution from the hypothetical factory gates. This can be the basis for a business-to-business environmental product declaration.

A cradle-to-grave approach tracks a product’s impacts until the disposal or recycling phase. The less-common “cradle to cradle” reaches to the point of product reuse, as in a rerefinery.

According to the ISO, an environmental product declaration “quantifies environmental information on the life cycle of a product to enable comparisons between products fulfilling the same function.”

The results of an EPD help a manufacturer to communicate a product’s environmental impact and a buyer to compare that impact with similar products during a business-to-business transaction.

Products are defined using specific product category rules, a patchwork of specifications developed by states and associations, which are verified by an independent third-party panel. Once verified, the EPD report can be registered and published.

The methodical approach of an LCA, using the ISO’s 14040 family of standards LCA and Eco-efficiency ISO 14040, ISO 14044 and ISO 14045 (see International Standards Organization), can be a useful tool for gathering data on all three sustainability pillars, not just environmental.

LCAs are pertinent to the lubricants industry because the products have identifiable environmental impacts, use phases and disposal requirements. Used lubrication products can be incinerated to create heat and electricity, recycled into other products and rerefined back into base oil.

LCAs are also useful for finding environmentally preferable alternatives to materials, products, systems and services.

Two more terms associated with LCA and sustainability are footprint and handprint. Footprint refers to the environmental impact, and measuring it helps reduce that impact as much as possible. The handprint approach aims to reduce a product or service user’s footprint, too. This is assessed by measuring the potential positive impacts when the product or service is used by a customer, as compared to a baseline.

*Embodied energy is energy consumed by all of the processes associated with production.