Battery electric vehicle enthusiasts like to tout their cars’ green credentials, and there is compelling data that shows EVs have a smaller carbon footprint over their lifetimes compared with internal combustion engine vehicles. But Polestar, a Swedish high-end EV company, thinks that is not enough.

Polestar recently announced its “moonshot goal” is to create the world’s first truly climate-neutral car by 2030. But to make an EV requires lots of electricity, not only to power the production line but also for the legions of raw materials and parts suppliers.

Other energy-intensive EV ingredients include the lithium and cobalt for the battery, steel for the chassis and plastics for the trim. Critics of the automotive industry point out these environmental impacts, as well as socia ones, such as child labor used in cobalt extraction in conflict-stricken Congo.

After an EV is made, it needs to be charged. This raises more concerns about the emission factor of the electricity generated wherever the car may be topping up its battery. At the end of the use phase of that battery, how to recycle or reuse it also becomes an issue.

Still, EVs are clearly the way road transport is heading, and whether they like it or not, most of the world’s biggest automakers are investing substantial sums into e-mobility and are at least making the efforts toward sustainability, too. These efforts include carbon offsetting, which doesn’t reduce the carbon produced but instead commits money to projects such as reforestation, renewable energy and landfill methane capture.

Environmentalists warn that offsetting is not sustainable in the long run and that planting trees or issuing carbon credits displace the problem elsewhere. Polestar’s CEO Thomas Ingenlath agrees.

“Offsetting is a cop-out. By pushing ourselves to create a completely climate-neutral car, we are forced to reach beyond what is possible today,” Ingenlath said in a news release.

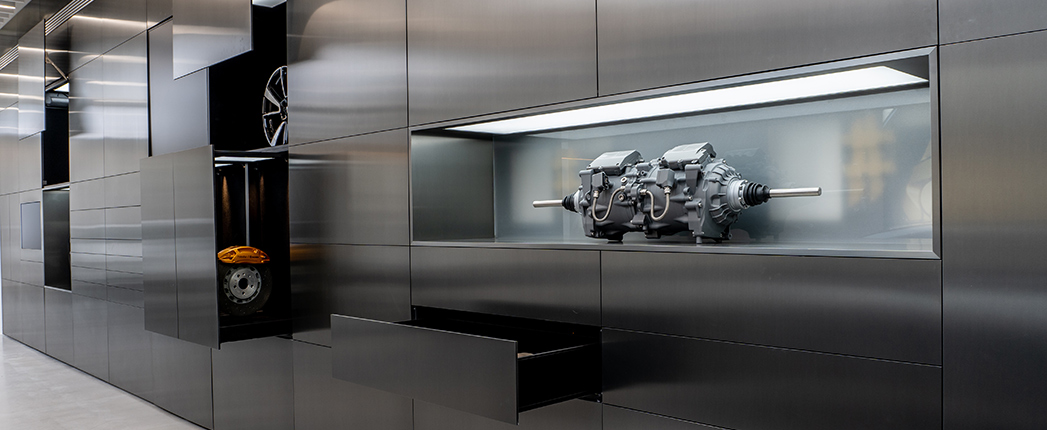

The company recently promoted its Polestar 2 performance EV in Europe and North America. The car includes several kilograms-worth of aluminum parts. According to the United Nations Environmental Program, to extract and process 1 kg of aluminum takes about 200 megajoules of primary energy and produces 8.24 kg of carbon dioxide. Just the assembly of an entire average-sized car requires about 48 megajoules.

About 80% of the world’s primary energy comes from hydrocarbons or coal, with about 10% from biofuels and waste and 10% from renewables.

“This means that any ‘zero-emission’ project always has a hidden, embodied carbon footprint,” Boris Zhmud, head of research and development at Berlin-based lubricant marketer Bizol, told Sustainability InSite. The production of genuinely climate neutral car is a formidable task,” he said.

Hypothetically, there could be a truly climate-neutral car manufacturing ecosystem, whereby all raw materials are extracted, transported and processed and tools and machinery are obtained and operated using renewable energy, he argued.

“In the end, it is … far more complex than just saying ‘I power my plant by hydropower’ or ‘I charge my car from photovoltaic solar panels’,” Zhmud said. “The world energy system is one big organism.”

Zhmud pointed out that unless you generate your own power, it is difficult to ensure whether or not your electricity supply is renewable, unless the local power company provides it.

“All users are connected to the same power grid that has its carbon footprint, and we all share the same atmosphere,” he said.

This leaves Polestar with a large hill to climb to reach a carbon neutral car without resorting to offsetting.

Sorry, a technical error occurred and we were unable to log you into your account. We have emailed the problem to our team, and they are looking into the matter. You can reach us at cs@lubesngreases.com.

Click here link to homepage