To win a race in motorsport, you need to drive faster than everybody else. However, there are a number of other less obvious factors that contribute to success on the track, one of which is having a solid team backing you. An integral part of that team is the lubricant provider, which supports its racing partners by helping to achieve maximum racecar performance.

Leonard Kieckebusch explores the fast-paced world of Formula E lubricants and explains how Shell Lubricants is using its experience on the track to improve electric vehicle lubricants for the everyday EV driver.

Evolution of the Racecar

When the lights went out on the very first ABB FIA Formula E Championship race in Beijing in 2014, EV technology was in its infancy. Today, thanks to nine years of experimentation, testing and adaptation on street circuits around the world, the electric technology on our roads has improved dramatically.

As the Gen1 car evolved to Gen2, then progressed to the Gen3 car that was launched at the start of the current season, Formula E cars have gained more power and speed, plus regeneration capabilities.

In 2014, the Gen1 car produced a humble 200 kilowatts of power, which was enough for it to hit a top speed of 225 kilometers per hour and regenerate 100 kilowatt-hours of power. Impressive for the time, the cars were also a radical shift away from anything that had gone before them in motorsport, catching the eye of curious bystanders and fans as they cut their way through the streets of some of the world’s greatest cities.

© Photo courtesy of Shell

From there, the technology stepped up a notch with the arrival of the Gen2 car in 2018. The Gen2 car boasted a 250-kW power pack and a top speed of 280 km/h, plus the ability to regenerate its entire operating power input. With a new, bolder look and enclosed front wheel arches, the Gen2 car ushered in a new era of Formula E, with numerous auto manufacturers joining the battle for victory as the series grew in stature. With new street circuits added to the championship schedule, the Gen2 car carried four different drivers to the top of the championship before its final outing in Seoul, South Korea, in 2022.

The current Gen3 car was launched at the start of the 2022/2023 season and is the result of lessons learned over the previous nine years of racing. The car boasts 350 kW of power and is capable of reaching 320 km/h and regenerating a staggering 600 kWh of energy. Compared to the Gen1 car, the Gen3 Formula E racer is 75% more powerful, has a greater top speed by 95 km/h and possesses six times the power regeneration capability.

The Vital Role of Lubricants

What role do lubricants play in the power, efficiency, durability, reliability and sustainability of the current Gen3 race car?

As with conventional EVs, the drive trains of Formula E race cars require a reduction gear set to reduce the high speeds of the e-motor and increase torque. For this, bespoke lubricants are needed, so “E-Fluids” are specifically designed for thermal management and wear protection of battery electric vehicle components.

In addition to lubricating the gearbox, E-Fluid technologies can be used for effective cooling of the electric motor. The combination of an electric motor and the gearbox in BEV applications is known as the “E-Drive unit,” and E-Fluids enable highly efficient immersive cooling of the battery system as well as faster charging and safer operation.

In Formula E, most racecar parts are identical for all race teams, so the most critical technical differentiation from the competition is the e-motor, the gearbox and the bespoke lubricant. Indeed, since the introduction of the new Gen3 racecars this season—with the maximum power increased from 250 kW to 350 kW—E-Fluids have come to play an even more vital role in protecting the hardware and enhancing the efficiency of the overall E-Drive unit.

Partnering with Race Teams

Since the start of season five in November 2018, Shell has been an official partner of the Nissan Formula E team, providing E-Transmission and Thermal Fluids. Since season seven, which began in November 2020, Shell has also been a technical partner of the Mahindra Racing team, providing E-Transmission Fluids.

To help the teams extract the maximum performance from the new Gen3 car, Shell has worked with the teams individually to co-develop a bespoke range of E-Fluids for the new Gen3 powertrain.

Power and Efficiency

The bespoke E-Transmission Fluids enable the transmission system to deliver more power while using less energy, providing Shell’s partners with a competitive edge when power and efficiency are critical. Driveline efficiency tests have proven that the dedicated race fluids have a significantly higher efficiency than conventional transmission oils and operate at lower temperatures.

Gas-to-Liquids (GTL) base oil technology enables Shell’s Thermal Fluids to maintain excellent dielectric properties over the full lifetime of the Gen3 car, delivering enhanced power and efficiency. The very low viscosity of Shell’s Thermal Fluids optimizes the efficiency of the e-motor and inverter. Thanks to their dielectric properties, the Thermal Fluids also enable the direct cooling of the electric motor and inverter in the car, resulting in better heat transfer between the heat source and cooling liquid to unlock higher and longer power peaks from the electric motor.

Durability and Reliability

Shell’s bespoke E-Transmission Fluids generate less friction compared to benchmarked competitor products, which enhance durability and reliability. The fluids have been tested over the course of more than 40 races, which represent a distance of 12,000 km without an oil change. No scuffing, pitting or extensive wear was observed during the durability test. The bespoke E-Fluid was subsequently run under actual race conditions and proved its ability to protect hardware. In fact, the fluid was used throughout season eight without any fluid-related gearbox issues.

Nissan’s Gen3 Formula E racecar. © Photo courtesy of Shell

Meanwhile, Shell’s Thermal Fluids are optimized for compatibility with the racecar’s electrical components and have non-corrosive properties to protect the car’s powertrain. This also results in increased durability and reliability.

Effective thermal management is key to protect sensitive electrical parts from overheating and ensure they operate safely. Effective thermal fluids, like Shell’s, ensure optimal insulation to maximize the performance of electrical equipment and prevent any damages caused by short circuits or creepage current.

Sustainability

All of Shell’s bespoke racing E-Fluids use an innovative base oil mix sourced from renewable biomass, resulting in more than 60% of contained carbon being biogenic. This reduces the carbon footprint by around 50% compared to a conventional Shell gear oil and leads to highly biodegradable content, supporting the sustainability aspirations of Formula E, Shell and Shell’s Formula E partners.

The Thermal Fluids are designed so that as the commercial volume increases, it will be viable to recycle the fluid into rerefined base oils.

Differences Between Race Fluids and EV Products

Shell’s partnerships in Formula E provide a platform of extreme driving conditions and a test bed for innovative lubricant concepts to support the continued development of its specialized E-Fluids. This has allowed the company to evaluate E-Fluids at up to 30,000 rpm and compare efficiencies of different base oil and additive concepts.

However, despite being highly efficient under race conditions, it is not recommended to use the bespoke racing fluids in conventional EVs. The racing fluids have been co-developed with Shell’s motorsport partners to enable full potential of the electrical drive unit, but they are not ideally suited for on-road applications. Why is this? The main difference between the two fluid categories are the requirements for thermal stability; conventional E-Fluids have more demanding requirements.

Most conventional E-Fluids are also designed for long oil drain intervals—up to lifetime lubrication. Conversely, even when all the races of a Formula E season are added together, the total distance a Formula E racecar will drive with one oil is shorter than the distance an everyday EV might drive. Moreover, the gearbox for Formula E cars can be cooled to a certain temperature, which also prevents degradation of the oil.

Testing Efficiencies

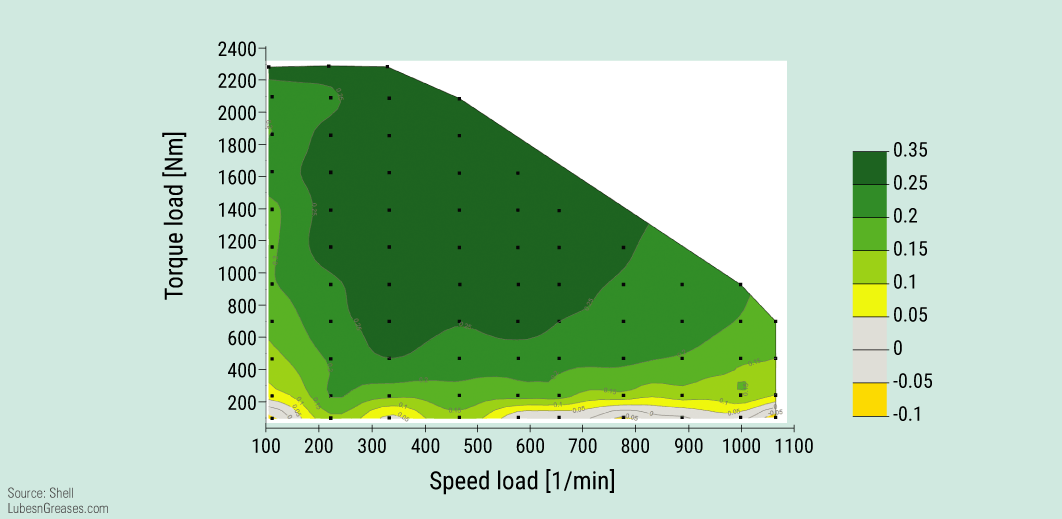

Shell’s team ran multiple driveline tests at its technology center in Hamburg, Germany, to identify the efficiencies of different fluids. A conventional reduction gear box from an electrified passenger car was used and all data points were collected and summarized in a so-called “efficiency map.” (See Figure 1.)

Figure 1. Efficiency Benefits of Race Fluid vs. Conventional E-Fluid in %

Figure 1 shows the benefits of a bespoke race fluid and a conventional e-fluid. Both fluids have a comparable kinematic viscosity at 100°C of around 4 mm²/s. The greener the area, the more efficient the race fluid. The main advantages are at high torque and relatively high speeds, with those extreme driving conditions being very important in motorsport but less important for conventional EVs driving in cities or on highways. Consequently, it is important to understand the actual driving conditions to develop or select a lubricant for the specific target application.

Another difference is that commercial products usually need to be globally available and producible on a large scale, all while being commercially attractive for customers; these are not requirements in the development of E-Fluids for Formula E. Therefore, Shell’s technical team was able to choose from a much broader component range, especially when it came to novel and innovative base oils, and to focus on the use of sustainable components and minimizing the carbon footprint of the lubricant.

From the Track to the Road

Despite the different vehicle requirements, the learnings from Formula E product development are being actively transferred from the track to the road. Racing fluids are feeding directly into the development of conventional E-Fluid products designed to optimize the efficiency of road-going EVs, where it is key to understand the individual hardware and develop bespoke E-fluids for the benefit of customers worldwide.

Shell was among the first companies to launch an E-Fluids portfolio in 2019, demonstrating technological readiness and achieving early traction with OEMs. Today, Shell’s Formula E partnerships are helping to drive Shell’s innovation in lubricants.

E-Fluids also represent the latest chapter in the company’s support to generations of motorsports teams that have benefited from Shell’s commitment to delivering lubricants that maximize the performance and efficiency of the finely tuned racecars in environments where milliseconds can make a major difference in race results.

More broadly, the company also supports the expansion of its Shell Recharge charging network, as it aims to become the global leader in EV charging services. This endeavor supports Shell’s target to become a net-zero emissions energy business by 2050.

Leonard Kieckebusch is project leader, e-fluid development with Shell Lubricants.