In past years, an increasing number of governments and corporations have announced net-zero emission ambitions to support the goals of the Paris Agreement and to limit the increase in average global temperature. These goals highlight the importance of how industry will account for the carbon content of the products it produces.

There will be increasing attention by customers to accuracy and consistency of carbon accounting approaches. In the lubricants industry, this need is being addressed by the American Petroleum Institute, which is working to create a recommended practice document on lubricant life cycle assessment and quantification of lubricant carbon footprints.

The pace of this transition will vary in different regions. In many markets lubricants will play an important role by enabling new engine and transmission hardware to operate efficiently and deliver improved fuel economy and longer oil drain intervals, both of which facilitate lower emissions. To allow for these improvements, both engine and drive train lubricants are trending toward lower viscosity, while continuing to protect the hardware.

Even when internal combustion engines stop being produced, there are lubricant applications that will still be required for fully electric vehicles and many ICEs will remain in the car park for decades to come. Full battery electric vehicles will require various fluids—including transmission fluids and heat transfer fluids—to ensure safe and efficient operation.

The Lube Industry Does its Part

Lubricants have long been partly responsible for increased fuel economy and reduced greenhouse gas emissions, and industry stakeholders have now made sustainability a core objective.

For instance, “Infineum’s purpose is to create a sustainable future through innovative chemistry, and never has this been more important,” Maurizio Abbondanza, Infineum’s sustainability director, said. “Sustainability is a business imperative for all companies that not only wish to survive but thrive. Stakeholders are demanding it, too. Sustainability is a source of profitable growth, as it is fundamental to everything we do as an industry and will provide the unique opportunity to transform our value chains and create new value.”

How are other major lubricant industry players contributing?

“Shell has set a target to become a net-zero emissions energy business by 2050, in step with society,” Gavin Warner, general manager of sustainability for Shell Lubricants, said. “This supports the more ambitious goal to tackle climate change laid out in the UN Paris Agreement: to limit the rise in average global temperature to 1.5° C. Shell’s current business plans do not reach 2050, but as society moves toward net-zero emissions, we expect Shell’s plans to reflect this movement. Sustainability is also a key element considered in activities right through the Shell Lubricants business, as we aspire to deliver improved performance with lower emissions, fewer natural resources and less waste.”

Selda Gunsel, VP of fuels and lubricants technology for Shell Projects & Technology, added, “We help customers manage their sustainability needs by providing premium products and cutting-edge technology to maximize performance and processes. Our advanced low-viscosity lubricants can deliver fuel economy and energy efficiency benefits and can also allow customers to extend their oil drain interval, all of which can lower emissions.”

Measuring Sustainability Efforts

While developing and setting sustainability goals is an important task, measuring real improvements and quantifying those reductions is a complex undertaking. It encompasses all aspects of the supply chain involved in making a product. It is also a global responsibility; how it is done across geographical boundaries matters. To support the drive toward simplicity and transparency, API has begun developing a recommended practice document for performing LCAs for lubricants with an initial focus on the impact category of global warming.

To accomplish this, a sustainability task force was formed in July 2021 after the call to action was led by Mike Alessi of ExxonMobil, who serves as chair of the Lubricant Standards Group. This effort will complement API’s efforts concerning fuels and look into the sustainability attributes of lubricants. The expertise to establish guidelines did not directly reside with LSG members, so subject matter experts were consulted to take a deep dive into the process of manufacturing lubricants sustainably.

Jeffrey Harmening, API’s senior manager of engine oil licensing systems, said that the industry “is committed to taking action to drive down emissions and advance a lower carbon future. API’s Climate Action Framework outlines steps our industry can take to address the climate challenge, including reducing emissions from our operations and accelerating the development of cleaner fuels. Meaningful and consistent methodology for life cycle analysis is crucial in helping determine the carbon footprint of lubricant products. Lubricant producers around the globe are attempting to make their own carbon footprint determinations, but varying methodologies make the process complicated and confusing. Our goal is that lubricant marketers and manufacturers could use this new recommended practice to assess and record the carbon footprint of their lubricants reliably and consistently.”

On July 20, 2021, a focused subcommittee met to define lubricant LCA methodology and its application to product carbon footprint calculations. The team was led by Andreas Glawar, carbon solutions advisor, Shell Projects & Technology, who took a coordinating role to facilitate the contributions of the SMEs. “In order to accomplish the sustainability goals at Shell Lubricants, reliable quantification and comparison of carbon intensity of components and products is key,” Glawar said. “Capturing best practice and applying it globally in terms of lubricants LCA methodology is an important step toward the industry being able to share product carbon footprints on a more comparable basis.”

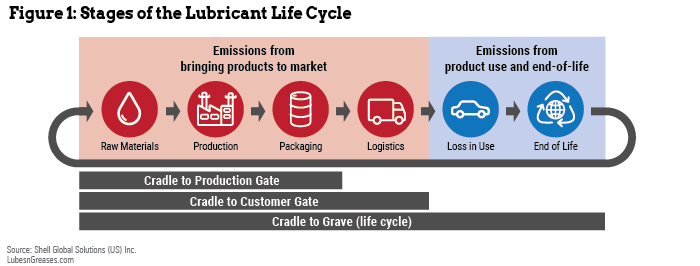

In this context, it is important to understand the scope and the terms used by SMEs in the quest to quantify lubricant carbon footprints and to deliver more sustainable products. To start, we must understand the life cycle of the lubricant. The life cycle can be defined as all the stages the product runs through. The stages include raw materials, production, packaging, logistics, losses in use and end-of-life. Recycling waste materials at the end-of-life stage allows resources to be fed back to the raw material stage in the life cycle (Figure 1).

When considering the product carbon footprint, one can look at the full life cycle or only a subset of the life cycle stages. There are many considerations and opportunities to improve the life cycle carbon footprint. The physical product can be made from less carbon intensive components as well as manufactured, packaged and transported to end users in more sustainable ways. Disposal routes and minimization of losses can also play a role. A clear distinction should be made between losses in the “in-use” phase, which are part of the life cycle, and certain benefits from use of the product, which can go beyond the product’s life cycle itself.

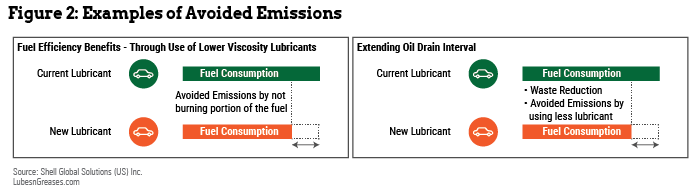

In this regard, it is important to consider the overall emissions impact as well as the additional in-use benefits a lubricant can provide. These can be quantified as “avoided emissions.” Such avoided emissions are defined in comparison to a reference scenario in which the product does not exist. This relative comparison is different from the absolute emissions considered in the life cycle calculation. Examples of avoided emissions from in-use benefits for lubricants include such things as increased fuel economy or energy efficiency, extended oil drain interval and lengthened engine or machinery life (Figure 2).

The magnitude of these in-use benefits can be significant—sometimes of a greater value than the carbon intensity of the lubricant. “Life cycle assessment is a technique for evaluating a product’s entire life cycle in terms of impact on the environment and contributions to sustainability from extracting and processing the raw materials and making and applying the final product through to treating the product at end-of-life,” Kevin Poindexter, Infineum’s sustainability manager, said. “You can use your LCA results to help improve production, inform strategic planning, aid product marketing and even support policy making. Improving efficiency through fuel economy contribution, extended drain interval and longer equipment life have been the drivers behind our additive technology investment for many years. This focus is sharpening with the rapidly increasing emphasis on product sustainability. This is one of the reasons why at Infineum we have been working to ensure that by 2025 100% of our products will be evaluated with sustainability criteria.”

Various organizations are seeking alignment in this space. To encourage alignment of approaches and sharing of learnings between global organizations, API will promote sharing of information between eight key industry groups including the Technical Association of the European Lubricants Industry, Verband Schmierstoff-Industrie and the Asian Lubricants Industry Association.

“Shell is excited to contribute to a collaboration effort toward a single global industry approach of performing lubricant LCA, avoiding region by region variation where possible,” Mark Southby, industrial liaison and sustainability lead for Shell Lubricants Technology, said.

“Working groups have been meeting twice a month and are currently developing the text of the recommended practice,” API’s Harmening said. “At this pace, we believe we can move forward with a draft in the spring to present to the API Lubricants Standards Group and other interested stakeholders for a balloting and comment period. Based on an ideal timeline, this new recommended practice could be published as early as July, which is a testament to the hard work and dedication of these groups.”

He added: “While members of the various work groups largely represent North American companies, API has successfully reached out to lubricant-related organizations around the world and established an impressive liaison group to harmonize efforts, terminology and practices as much as possible. To that end, the published recommended practice is likely to remain a “living document” that can be adapted as methodologies improve or scopes expand beyond today’s needs.”

The initial efforts will focus on the product and associated life cycle and not propose detailed guidelines concerning in-use benefits. Users will need to determine the in-use benefits, the appropriate reference to measure those against and who gets credit for the reduction.

“The entire industry is now facing the challenge of delivering ongoing performance improvement while supporting the drive to lower carbon footprint products,” Poindexter said. “Infineum is focusing on more efficient energy consumption at our plants and collaborating with suppliers to accelerate environmental and social improvements across our value chain. Product carbon footprint as well as LCA are critical in quantifying the benefits and impacts of oil additives. Establishing common methodology for performing this analysis, along with consideration of how it should be applied to performance specifications, would benefit the entire industry.”

Steve Haffner is president of SGH Consulting LLC. He has over 40 years of experience in the chemical industry, primarily with Exxon Chemicals Paramins and Infineum USA. Contact him at sghaffn2015@gmail.com or 908-672-8012.