Amid heightening efforts around sustainability in transportation, there has been a lot of excitement in recent years about the promise of electric vehicles. Although it is true that the vehicle parc continues to shift toward electrification, it would be an oversight to forget about the internal combustion engine, as these vehicles will likely make up the majority of the global vehicle parc for the foreseeable future. Because of this, there is still a need to support the technology that currently comprises the largest portion of the global vehicle parc. But this must be done while making improvements with new entries.

With the aid of advanced aftertreatment systems, significant improvements to engine hardware design have allowed modern ICE vehicles to achieve exceptional levels of efficiency and to meet the most recent lower emissions regulations. These improvements in efficiency have manifested in both light-duty and heavy-duty categories, and have increased the demand for higher-performance lubricants that enable modern hardware to operate correctly and to protect the valuable aftertreatment systems.

It is expected that these trends will continue. After all, lubricant technology must evolve to support a more sustainable future.

However, paramount to that expectation is also a recognition that additive and performance polymer technology alone can only take the lubrication industry so far in its collective drive to achieve greater sustainability. Equally essential are the materials that make up the majority of lubricant formulations: base oils.

The optimal base oil for a given application, combined with advanced additive and performance polymer chemistry, can help technologists maximize the performance of their fluids while simultaneously supporting ever-increasing sustainability efforts.

This article will explore why base oil selection is critical to creating complete lubricant formulations that can contribute to a more sustainable future.

A Brief Assessment of Today’s Base Stocks

A formulator’s reasoning for base stock selection for a given lubricant formulation largely depends upon the application of the final product. Modern engine designs have imposed limits on lubricant elemental levels to ensure more optimal catalyst operation, and volatility restrictions similarly lessen hydrocarbon emissions.

The trend toward lower-viscosity oils has also driven the market to adopt API Groups II, III, IV and V as preferred options.

To take it a step further, sustainability now needs to be overlaid on those considerations as an extra parameter of importance. Complete life cycle analyses, along with carbon handprint and footprint considerations, offer useful frameworks.

Life Cycle Analysis

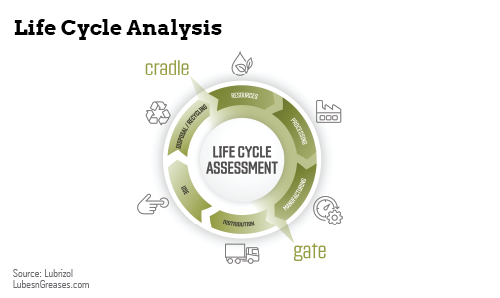

Formulators can use a complete life cycle analysis—commonly referred to as an LCA—to confirm the sustainability of the fluid design choices that have been made. (See Figure 1.) This should be a holistic cradle-to-grave view, taking into account factors such as greenhouse gas emissions, energy consumption, water usage and more.

Handprint and Footprint

Another way to conceive of comprehensive sustainability is to think about your company’s products and operations in terms of their footprint and handprint.

What do these terms mean, and how can they help to structure your company’s sustainability efforts?

A company’s footprint is the total environmental impact of its operations. An organization can shrink the size of its footprint by producing products in a safer, more efficient and more responsible manner, helping to minimize emissions while also protecting natural resources. For a lubricant maker, the environmental impact of its base oil supplier is a part of the lubricant supplier’s own footprint.

A company’s handprint is the positive impact of its products in their end-use applications. For example, an efficient engine oil in an ICE vehicle can help the vehicle to produce fewer emissions and to consume less fuel.

A lubricant company can extend its reach and maximize its handprint by providing products and services that meet or exceed customer sustainability goals. In essence, this happens by getting the right lubricants into the marketplace and ensuring that end users are employing them in the correct applications. A higher-quality lubricant formulation can contribute to higher levels of performance and improve efficiency, all while helping lubricant companies to grow their handprint.

Evaluating Impact

Because a formulator’s choice of base oil will comprise upward of 75% of the final fluid, it is important to evaluate the full scope of that base oil’s contribution to the fluid’s overall sustainability and performance profile.

To begin, it is helpful to establish what “sustainability” truly means in this context. The term should encompass how an organization conducts its business from top to bottom. That includes how it sources raw materials (such as base oils or the materials used to blend them), how it manages its supply chain as well as how it sources energy to power its operations.

To those ends, the Greenhouse Gas Protocol (GHG) provides a thorough framework for understanding the various sources of emissions, which are organized into three categories: Scope 1, Scope 2 and Scope 3 emissions.

- Scope 1 emissions account for an organization’s direct greenhouse gas emissions. These encompass emissions from sources owned or controlled by that organization.

- Scope 2 emissions are indirect greenhouse gas emissions associated with an organization’s purchase of energy, such as electricity, steam, heat or cooling.

- Scope 3 emissions account for the result of activities from assets not owned or controlled by the reporting organization. These emissions do indirectly impact the organization’s value chain, though.

Many businesses place the greatest emphasis on their Scope 1 emissions. This makes some sense: By definition, Scope 1 emissions are the ones most directly under an organization’s control, and it can make efforts internally to curtail them.

But to drive more holistic sustainability efforts, it is critical to also consider Scope 2 and Scope 3 emissions, which can be done by evaluating an organization’s entire value chain and working with partners who are committed to unlocking sustainability benefits. No company can deliver a more sustainable value chain alone; greater collaboration across the industry is key.

Considerations for Improvement

By applying life cycle analysis methodologies, lubricant manufacturers can better evaluate the sustainability profile of their base oils (namely footprint) and balance those attributes with the performance needs and efficiency contributions of their products (namely handprint). Meanwhile, there is an opportunity for base oil manufacturers to elevate the sustainability of their own processes and products to help deliver greater value for the market.

What’s Next?

It is imperative that organizations think critically about the environmental impacts of every part of their operations and manufacturing. Base oil manufacturing and selection represent a critical part of the lubricants industry’s ability to contribute to more complete sustainability. Subsequently, base oil manufacturers have a similar opportunity to distinguish themselves from their competitors by exploring more sustainable manufacturing practices.

The lubricants industry has had significant success enabling more sustainable travel and production in the world. It has commercialized engine oils that have enabled the wide range of aftertreatment hardware. It has also significantly reduced NOx emissions and particulates while ensuring durability of the hardware.

As the world continues to look for ways to reduce emissions and foster greater sustainability, we must dig deeper, work together and realize our potential to make a lasting difference for society. The lubricants industry as a whole has been tasked with enabling more efficient performance in a way that protects hardware for as long as possible and minimizes footprint throughout the entire value chain. That includes how we think about, manufacture and apply the right base oils for formulation in finished products.

It is vitally important to address the overall needs of the world’s evolving vehicle parc—both through modern ICE technology and the latest electric vehicle solutions. There is a need for continued investment in the lubricants marketplace as well as continued collaboration across the value chain to provide solutions that address the needs of the entire vehicle parc.

Colin Morton is Lubrizol’s senior business director for the global consumer engine lubricants business. He has over 20 years international experience in the specialty chemicals industry in both technical and commercial roles.

Dave Duncan is Lubrizol’s senior director, business excellence, covering both the industrial and transportation sectors. He has more than 35 years of experience in the lubricant additive industry, including a variety of technical roles for hydraulics, marine, small engine, passenger car, heavy-duty and fuels.