The United Nations has recently defined sustainable development as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs.” This concept has guided all companies that develop products as sustainability becomes a priority. In the case of lubricant technologies, it is important for technology and product management teams across the board to keep sustainability in mind as it comes under scrutiny from governments, original equipment manufacturers and consumers.

To measure sustainability profiles, lubricant formulators must perform life cycle assessments to ensure products are being sourced, produced and handled in a responsible and efficient manner that minimizes the carbon footprint while preserving and protecting natural resources. In this article, we will examine why life cycle assessments are important, what new technologies offer to improve overall sustainability and what role these different technologies—whether environmentally low-impact products or energy-efficient performance polymers—play in improving the sustainability of industrial lubricants, including hydraulic fluids, industrial gear oils and open gear lubricants.

Why Now?

It is important to realize that sustainability does not and cannot happen in a vacuum. No single country or company can achieve sustainability goals on its own. Building a more inclusive future for people and the planet is vital to the Earth’s survival. In addition, the recent COVID-19 pandemic has led more companies to examine how they might change their business practices to be more environmentally sustainable.

|

It is important to realize that sustainability does not and cannot happen in a vacuum. No single country or company can achieve sustainability goals on its own.

|

The new pressure on governments around the world to regulate with consideration for sustainability is coming from more socially aware consumers, who in turn are pushing their politicians to promote more sustainable actions. The momentum to create a sustainable world is everywhere, and it shows few signs of slowing down.

Sustainability in the Lubricants Industry

Not only are sustainable practices the right thing to do for the planet and its people, but they are also a vital driver of the health and growth of companies worldwide. As such, corporations must take their sustainability commitments seriously. Part of making sure those commitments are fulfilled is undertaking life cycle assessments before new technologies are developed.

Life cycle assessment is the factual analysis of a product’s entire life from a sustainability standpoint. With a life cycle assessment, the environmental effects of a product or service are evaluated from raw material extraction through disposal or recycling. This prevents burden-shifting between different phases of a product’s life cycle and provides a standard for equally measuring all sustainability factors at the same time. Because of this, unintended factors of production, like food deprivation, deforestation and poor treatment of workers cannot be overlooked, bringing visibility to the circular effect that is needed to preserve the ability of future generations to meet their needs.

In other words, product development teams must have the tools and skills to develop products that are truly better for the environment. This allows companies to engage both suppliers and customers as they support one another in meeting sustainability goals. Life cycle assessment helps bring sustainability to the forefront, alongside product performance and cost.

Two terms are critical to understanding what role life cycle assessments will play in determining how sustainable products really are: footprint and handprint. Simply stated, environmental footprint is the effect that a person, company or activity has on the environment—for example, the amounts of natural resources that they use or harmful gases they produce.

The positive impact of products in use is referred to as their handprint. Maximizing the handprint of products by providing solutions that meet and exceed performance and sustainability goals targeted by consumers should be the focus of all product and technical teams.

The development of sustainable industrial lubricants does not happen by accident. Three broad approaches can be used: designing products with low environmental impact, use of energy-efficient performance polymers and development of additive packages to extend the drain interval. While increasing handprint is important, it is equally essential that new lubricant products meet or exceed industry and OEM credentials, as well as performance requirements.

Developing Products with Low Environmental Impact

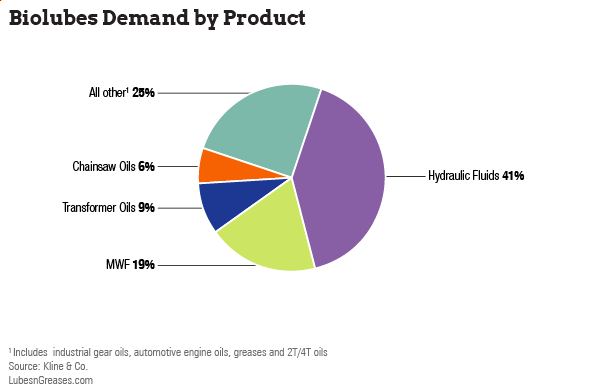

More organizations are trying to use products with lower environmental effects, so that they comply with increased government regulations and address the overall environmental awareness of consumers. While many different classes of products can be covered under this category, biolubricants are the most important product category.

Biodegradable hydraulic fluids are the most popular sub-class of biolubricants and are commonly used in sensitive areas, like forests and waterways, as an environmental protection measure. Environmentally acceptable lubricants are the most coveted of all biodegradable hydraulic fluids because they have demonstrated biodegradability, minimal aquatic toxicity and non-bioaccumulative potential while using biobased raw materials.

To be labeled an environmentally acceptable lubricant, a lubricant must meet many criteria. The best-in-class environmentally acceptable lubricants balance performance credentials mandated by industry standards and OEM specifications (ISO 15380, JCMAS HKB, Eaton and Denison) along with environmental requirements, like EU Ecolabel, VGP and USDA BioPreferred.

Energy-Efficient Performance Polymers

The use of energy-efficient performance polymers in hydraulic fluids, industrial gear oils and open gear lubricants can create sustainable solutions across the gamut of industrial products. Formulations with these polymers can increase productivity, reduce energy consumption or fuel usage, and reduce carbon dioxide emissions.

Unlike automotive applications, there is neither a Corporate Average Fuel Economy standard for energy-efficient hydraulic fluids nor testing protocols to define energy efficiency. In the absence of a standard testing protocol, it is important to use a well-defined scientific protocol with built-in statistical validation to develop fluids with energy efficiency. One such approach could be the use of a four-step strategy that includes bench tests, rig tests, controlled field evaluation and proof of performance in real-world field tests. The results must be validated statistically. Through these series of evaluations, an energy-efficient hydraulic fluid formula can be developed that shows consistent efficiency gains without impacting reliable performance.

For instance, an energy-efficient hydraulic fluid containing a performance polymer showed diesel fuel savings of up to 2.7% when tested in a field trial using heavy-duty mobile equipment. In addition, when tested in a plastic injection molding machine, this formula allowed for an 8.5% reduction in electricity usage. Such reduction in electricity or fuel usage can be translated into significant reduction in carbon dioxide emissions and can offer a tangible, sustainable solution.

To achieve increased energy efficiency without compromising durability, the use of an energy-efficient performance polymer will be necessary in combination with a performance additive with proven OEM credentials. A uniquely engineered class of performance polymers with superior thickening efficiency and exceptional shear stability will be able to reduce traction coefficients and increase energy efficiency while decreasing secondary flow losses.

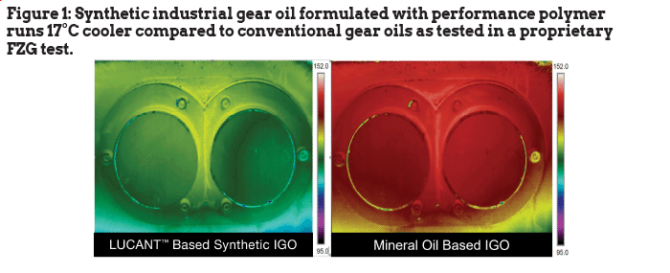

Such unique performance polymers can also be used in formulating both industrial gear oils and open gear lubricants. Applications that need differentiated performance often use synthetic industrial gear oils, typically formulated with polyalphaolefin-type base oil and thickeners; however, such synthetic industrial gear oils are expensive. Performance polymers in combination with PAO base oil can offer an alternate way to formulate a synthetic industrial gear oil with improved temperature reduction properties.

Because of its superior thickening efficiency, a lower treat rate of performance polymer will be required, offering a more cost-effective approach to formulate synthetic industrial gear oils. Compared to industrial gear oils formulated with a conventional mineral oil, such synthetic industrial gear oils containing the performance polymer can run 17°C cooler with 16% reduction in electricity consumption when tested in the FZG rig shown in Figure 1.

Additionally, open gear lubricants with performance polymer have been shown to run 21°C cooler and offer 20% energy savings compared to open gear lubricants formulated with mineral oil in the same test described above. In a field trial conducted in a sugar mill, the open gear lubricant formulated with performance polymer ran 10°F cooler than the incumbent lubricant, which ran hotter—even with water cooling—and led to severe wear damage. The clear appearance of the open gear lubricant containing performance polymer helped expedite the cleaning process and offered an additional benefit over the incumbent product.

In summary, the use of performance polymers in formulating industrial gear oils and open gear lubricants can allow them to run cooler and offer extended gearbox durability, which means longer times between replacement of oil and equipment. With less waste, the operations become more sustainable over the long haul.

Sustainability in Product Design

As lubricant manufacturers move forward with designing more sustainable products, consideration of the entire life cycle is vital. Focusing on continuous improvements in growing positive impact and paying attention to both footprint and handprint in product design will offer companies an edge over others with a limited focus on sustainability. Balancing sustainability while delivering high-performing products with be the key to success in the lubricants business now and in the future.

Derek Newbould is global strategic marketing manager for Lubrizol. Newbould joined Lubrizol in early 2019 and is responsible for developing strategies for current and future industrial lubricant markets. He focuses on the development and deployment of sustainability strategies for Lubrizol Additives.

Shubhamita Basu, Ph.D., is the North America product manager for industrial oils at Lubrizol, where she manages the hydraulic fluid, industrial gear oil and turbine oil portfolio. Basu has worked extensively in developing new molecules, engine oils and limited slip-gear oil applications, as well as formulating hydraulic fluid and industrial gear oils. She has also led an energy efficiency initiative and spearheaded environmentally acceptable lubricant development.