Multipurpose fluids play a key role for electric vehicle motors as evolving technologies raise cooling and lubrication performance requirements, a TotalEnergies official said in a presentation at an SAE International online event last month.

“Formulating a multipurpose fluid is tricky as you have to reduce viscosity to increase efficiency while maintaining the oil lubricating power and the other properties as a high standard,” Hakim El Bahi, a research engineer for French energy company TotalEnergies, said in his presentation, “Comprehensive Study of Cooling and Lubrication of Electric Drive Units Based on an Innovative Multipurpose Fluid,” at SAE International’s Powertrains, Fuels and Lubricants Digital Summit held Sept. 28-30.

El Bahi, who works on formulation of fluids for electric vehicles, noted as a case study example how the cooling system and power density of the electric motor in the Toyota Prius hybrid evolved over four generations – 1997, 2003, 2009 and 2015. “Reducing the size and weight of the e-motor is the main driver of e-motor development,” he said. “By doing so, heat dissipation area is decreased, so the improvement of e-motor cooling becomes crucial in order to achieve this quest of increasing power density.”

This led to the concept of oil cooling for the electric motor, instead of the standard water jacket cooling of the first and second generation of the Prius, he said. The 2009 third generation Prius used an oil-cooled stator heads and water jacket system. In an electric motor, the stator – which is stationary – provides a magnetic field that drives the motor’s rotating armature. The fourth-generation version in 2015 used an oil jacket and hollow shaft to make the electric motor fully oil-cooled. “This is the concept of oil cooling, and as a lubricant manufacturer, at Total Energies we have to design a multipurpose fluid that is lubricant for the transmission and bearings as always, and a coolant as well for the electric motor,” El Bahi explained.

EV multipurpose fluid must meet several new requirements, he said, including dielectric properties, thermal properties, material compatibility, durability and efficiency. Dielectric properties means that because the fluid is in direct contact with the electric motor, the fluid should be insulating enough to avoid any short-circuit phenomenon, El Bahi said.

The thermal properties requirement means that, because the fluid is used as a coolant for the electric motor, “We have to make sure that the fluid has a good heat extraction capacity,” he said.

Material compatibility refers to the need for the fluid to be fully compatible with all the kinds of materials that exist in the electric motor.

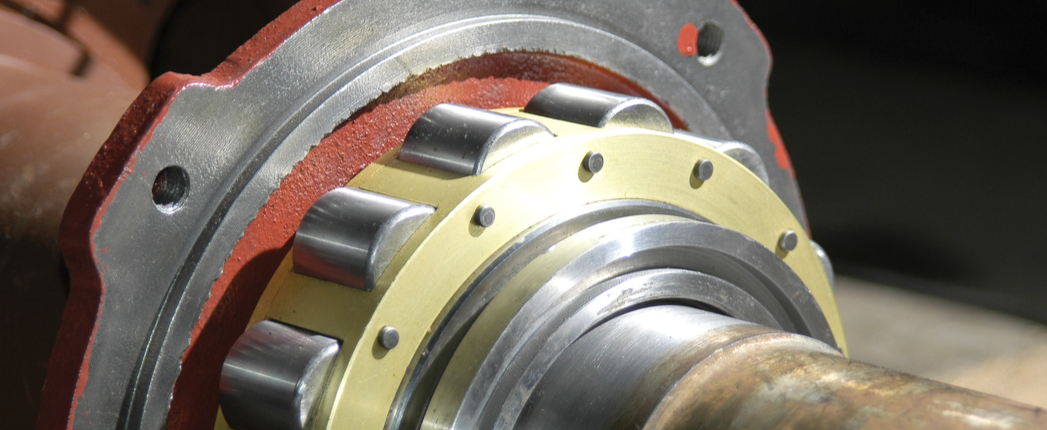

Durability tests for the fluid include FZG scuffing, wear and high-speed bearing tests, while efficiency requirements include mini-traction machine friction test and high-speed aeration test. Durability and efficiency are key challenges for fluid development for electric motors because of the high-speed dimension, he said, noting that motor speed can exceed 10,000 revolutions per minute, and delivery very high torque at low speeds.

To better understand the question of electric motor cooling, TotalEnergies partnered with RWTH Aaachen University in Germany, conducting both simulation work and experimental machine model work. They compared two cooling architectures. The “old way” consisted of a water jacket using glycolated water circulating around the stator. The new cooling architecture is a direct oil cooling system – of the type used in Tesla brand electric vehicles – with an oil jacket, outer jet coming from the oil jackets and a hollow shaft and inner jet.

Within the direct oil cooling system, the companies compared the high reference automatic transmission fluid to a high performance multipurpose fluid. The high performance multipurpose fluid showed a better performance than water jacket cooling and than the high reference ATF, he said. “Thanks to its lower viscosity, high performance MP fluid has a better cooling power,” El Bahi noted.

He added that even with its very low viscosity, high performance multipurpose fluid shows a high dielectric performance and a good stability at high temperatures.

The multipurpose fluid also performed well in FZG scuffing and wear tests. Even with its very low viscosity, he said, the fluid showed an outstanding load-carrying capacity. In tests, he said, the high performance multipurpose fluid generated less friction than reference ATF fluids

A high-speed step test was conducted to measure bearing lubrication performance. The test consists of increasing step wise state of ball bearing from 8,000 RPM to 30,000 RPM, each step lasting one hour under a specified load. Results show a multipurpose fluid can maintain the speed targets with an acceptable level of vibration, which is not the case of the Japanese ATF, where a sudden increase of vibration is observed at 21,000 RPM, he said.

“We have seen that a multipurpose fluid which integrates both cooling and lubrication purposes is a proven concept that fulfills requirements for electric vehicles,” he said.

For more coverage of electric vehicles and their impact on lubricants, subscribe to Lubes’n’Greases’ Electric Vehicles InSite.