There are a number of potential avenues of development and challenges for electric vehicle lubricant formulators, but whatever path they take, comprehensive understanding and testing is essential, say an international group of tribologists.

Sales of electric vehicles grew in leaps and bounds over the past decade, as environmental authorities the world over placed evermore emphasis on fuel efficiency and emissions reduction to curb climate change and urban air quality. In parallel, this led to the development of a handful of dedicated lubricating oils and greases for electrified drivelines.

Like their internal combustion engine oil counterparts, these lubricating products must minimize friction, enhance durability, bolster efficiency and reduce noise. Yet they must also conform to the complex electrical components found in these new vehicles while maintaining thermal cooling and corrosion prevention properties, as well as being filled for life. In addition, they have to be adapted to high-speed reduction gears and electric motors. Fulfilling this matrix of characteristics is crucial to EVs taking the next big step toward being the future of mobility.

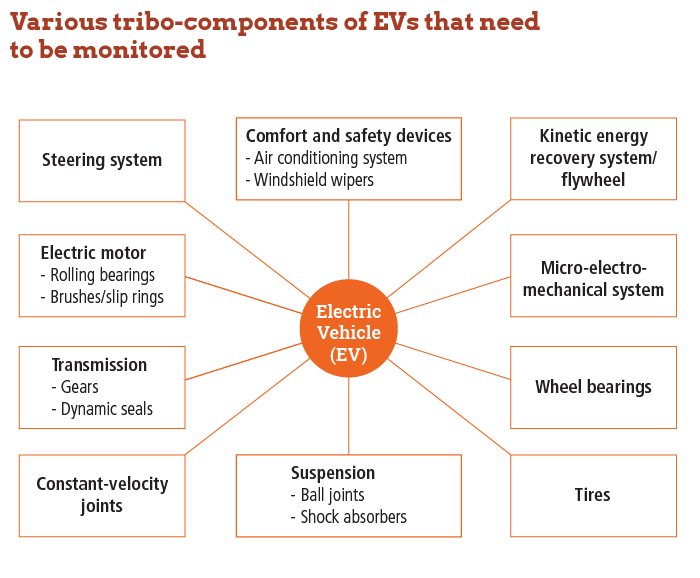

Several lubricant formulators have presented their first lines of dedicated EV fluids and lubricants. Despite the increased technical stringency for EV lubrication standards and the severity of the lubricating environment, the significant reduction of moving components removes the need for conventional engine oils (however, this will still exist in hybrids). Instead, EV lubrication focuses on components such as roller bearings, gears and the driveline.

Roller bearings, for example, may be lubricated by either lubricating oils in gears or greases in other driveline components, with the distinction between an oil and a grease being in differences in viscosity and their sealing capabilities. In order to decrease friction in a roller bearing, especially during hydrodynamic lubrication (whereby a wedge of fluid exists between non-parallel rigid bearing surfaces), it is necessary to reduce the viscosity of the applied lubricant and/or to identify effective friction modifiers. Thus, lubricating oils allow for a greater reduction in friction due to their lower viscosity in comparison with greases. Second, hydrodynamically lubricated sliding contacts have very good capacity to dampen noise.

Louder vehicle noise derives from combustion in ICEs at low speeds, whereas sound from tires and wind are more prevalent at high speeds. Excessive traffic noise can cause hearing damage and even cardiovascular diseases. E-motors are steadier and produce less noise than ICEs but nonetheless require an appropriate grease to mitigate this issue, especially at speeds of 20,000 revolutions per minute.

Conversely, the higher viscosity of greases allows for the lubricant to remain in the bearing without significant leakage. As such, 80 to 90% of roller bearings are lubricated with greases. Furthermore, current low-viscosity oil technologies were found to promote micro-pitting within rolling contact surfaces as a result of zinc dialkyldithiophosphate additives.

Greases in rolling bearing elements form very thin films in the range of some tenths of nanometers, due to Hertzian contact stresses between 3 and 4 gigapascals. Most tribo-systems in an ICE form sliding contacts with much thicker oil films. Therefore, research into wear characteristics of greases for rolling contacts in EVs should be conducted.

Frictional energy lost to gears has been attributed to approximately 8% of total frictional energy loss in an average passenger vehicle. Therefore, reducing friction in gears can improve the efficiency and range of EVs. Indeed, there is room for further reductions in oil viscosity, as expressed by the recently added gear oil grades 65, 70 and 75 to the SAE J306 gear oil standard, but also water-based gear oils thickened by polyalkylene glycols are under evaluation, which combine cooling and extreme pressure load-carrying capacities.

Currently, most gears in EVs are lubricated with gear oils that have been modified to have increased oxidative stability, anticorrosion protection, copper compatibility and good seal compatibility. Similar to many lubricants, the introduction of additives and the reduction of a gear oil’s viscosity are necessary for greater friction reduction during operation.

The very high speeds of e-motors of up to 20,000 revolutions per minute represent another driver for reduced oil viscosities. Most notably, nano-particle additives of multi-walled carbon nanotubes have been shown to improve the friction and wear of mineral gear oils, particularly at concentrations of 0.5% by weight. These new approaches remain functionally and cost competitive with traditional chemical-driven additive concepts.

The lubrication of an EV’s driveline is nearly identical to a corresponding driveline of the average ICE passenger vehicle. However, an EV requires the lubricant to not only maintain a low viscosity to reduce friction but to also reduce the corrosion of wiring and electronic components made of copper. As such, conventional mineral or synthetic lubricants may be altered to fit the needs of EVs through the use of certain additives. But some additives may in fact shorten the life span of a grease.

Tribological performance testing for EVs aids further evaluation and understanding of these advanced lubricants’ characteristic, and various tests should be performed to ensure specifications are met. The table below sets out specific properties that must be tested today.

Laboratory test specifications for current wheel bearing lubricants

| Test specifications | Required characteristics |

|---|---|

| DIN 51819 FAG FE8 (wear of rollers) | Superior wear properties under accelerated rolling contact fatigue |

| DIN 51821 FAG FE9 | Grease life/oxidation stability |

| ASTM D2265 Dropping Point | High operating temperatures |

| IP 121, ASTM D1742, ASTM D6184 | Excellent oil release properties |

| ASTM D4170, D7594 Fretting | Fretting wear resistance and low friction |

| SNR FEB2 (company test) | False brinelling test |

| ASTM D6138 Anti-Rust Test | Corrosion resistance |

| ASTM D1478 Col start torque | Low-temperature torque |

| ASTM D4950 NLGI Grade | Consistency |

| ASTM D217 Worked Cone Penetration (100Kx) | Mechanical/work stability |

| ASTM D1831 Grease roll stability | Resistance to physical degradation |

| ASTM D2266, D2596, D7421, D5706 | Extreme pressure properties |

| ASTM D1264 Water wash out | Water resistance |

| ASTM D4289 Elastomer compatibility | Seal compatibility |

| Source: Kuldeep Mistry, The Timken Co. |

Efficiency is another area of focus and correlates directly with the torque properties of EVs. Increasing useful torque by decreasing friction in the powertrain reduces the consumption of energy sources for all propulsion systems and transduces especially for EVs into longer range.

There have been approaches to making changes with gears, such as enhancing them with nanoparticles made from alumina, carbon or graphene. Coatings for gears made from double-glow plasma alloying with tungsten-molybdenum, tungsten carbide-carbon compounds and plasma nitriding have been applied as well, all of which have shown improvements in reducing friction and wear.

Coatings on gears made by thermo-chemical treatment, such as double glow plasma alloying with tungsten-molybdenum and plasma nitriding, or thin film coatings such as tungsten-doped diamond-like carbon and tungsten-doped DLC deposited on chromium nitiride, molybdenum nitride, have been applied as well, all of which have shown improvements in reducing friction and wear.

Additionally, one study reported a lubricating grease containing a silicon dioxide nanoparticle additive at 0.3% by weight that had a very low coefficient of friction and could help to reduce wear. Additives containing magnesium, phosphorus, and sulfur synergistically acting together also showed a reduced friction coefficient.

Other than for performance purposes, the developing lubricant must be compatible with the electrical components such as electric modules, polymeric insulations, sensors and circuits. E-motors generate lots of heat and inductive currents that must be insulated from the electric modules. In terms of electric properties, a good balance of conductivity must be found.

Electrostatic charges can build up if the conductivity of the fluid is too low, and this can cause degradation in the fluid and can lead to sparks. The very dangerous situation of current leaking can arise if the conductivity is too high. Oxidation in oils is also known to increase electrical conductivity.

In today’s ICE vehicles, lubricants made from mineral oils and typical additive packages lack the thermal and oxidative stability that is essential in an EV lubricant. Improvement in oxidative stability is gained with the use of synthetic-based oils made from molecules like polyalphaolefins, esters and polyalkylene glycol or estolides.Incorporating synthetic oils and boron compounds into gear oils has also been shown to increase thermal and oxidative stability, both very important after the introduction of an e-motor. These types of base oils and additives are very promising for their use in EVs, but more investigation is needed into how they will interact with the electric components.

Thermal and oxidative stability can be enhanced by adding electrically conductive nanoparticles or advanced polymers, such as rubber, polypropylene and methylpentene, which have all shown promising results in high-speed applications. Additives such as antioxidants and pour-point depressants and chemical modifications, such as transesterification and epoxidation, make a contribution too.

Advancements have also been made in bio-materials that could also provide dedicated EV lubricants with thermal and oxidative stability. With unavoidable concerns over the environment and sustainability, biodegradability and reduced toxicity are a trending development.

Biolubricants can be formulated based on base oils synthesized from renewable resources, like animal fats, microalgae, hydroxy fatty acids from plants such as Jatropha curcas, mastwood, pongnam oiltree, rubber seed, castor and jojoba oils, or any biomass, like lingo-cellulose or sugar.

The polarities in the molecular backbones of most biolubricants, such as esters and PAG, have also been shown to display better lubricity properties than mineral or synthetic hydrocarbon oils.

EVs and electrified drivelines are already the spearhead of a global push to develop more environmentally friendly systems across our daily lives. Even though sales of BEVs and PHEVs froze earlier this year after a peak of just over 2.26 million units in 2019 – an increase of only 9% from 2018 – that swelled the fleet to about 7.5 million four-wheelers in the world, demand will no doubt return and the need for dedicated lubricants will continue to be pressing.

All of the lubrication advancements mentioned have worked in ICE vehicles and show much potential for application in EV systems. However, there is still much testing needed to determine their electric properties and how they will interact with the e-motor and battery. What is clear is that progress made in the development of dedicated EV lubricants is drawing closer to synchronization with the mainstreaming of EVs.

Raj Shah is a director at Koehler Instrument Co. and a chartered petroleum engineer and elected fellow at numerous organizations. He is also an adjunct professor and the chair of the external advisory board of directors for chemical engineering at Stony Brook University.

Mathias Woydt is managing director of Matrilub and has more than 34 years of experience in R&D and more than 340 publications and 51 priority patents filed. Woydt is also board member of the German Society for Tribology. He is recipient of the ASTM award of Excellence.

Nathan Aragon and Issac Kim are chemical engineering students at Stony Brook University and are part of the internship program at Koehler instrument Co.

Sorry, a technical error occurred and we were unable to log you into your account. We have emailed the problem to our team, and they are looking into the matter. You can reach us at cs@lubesngreases.com.

Click here link to homepage