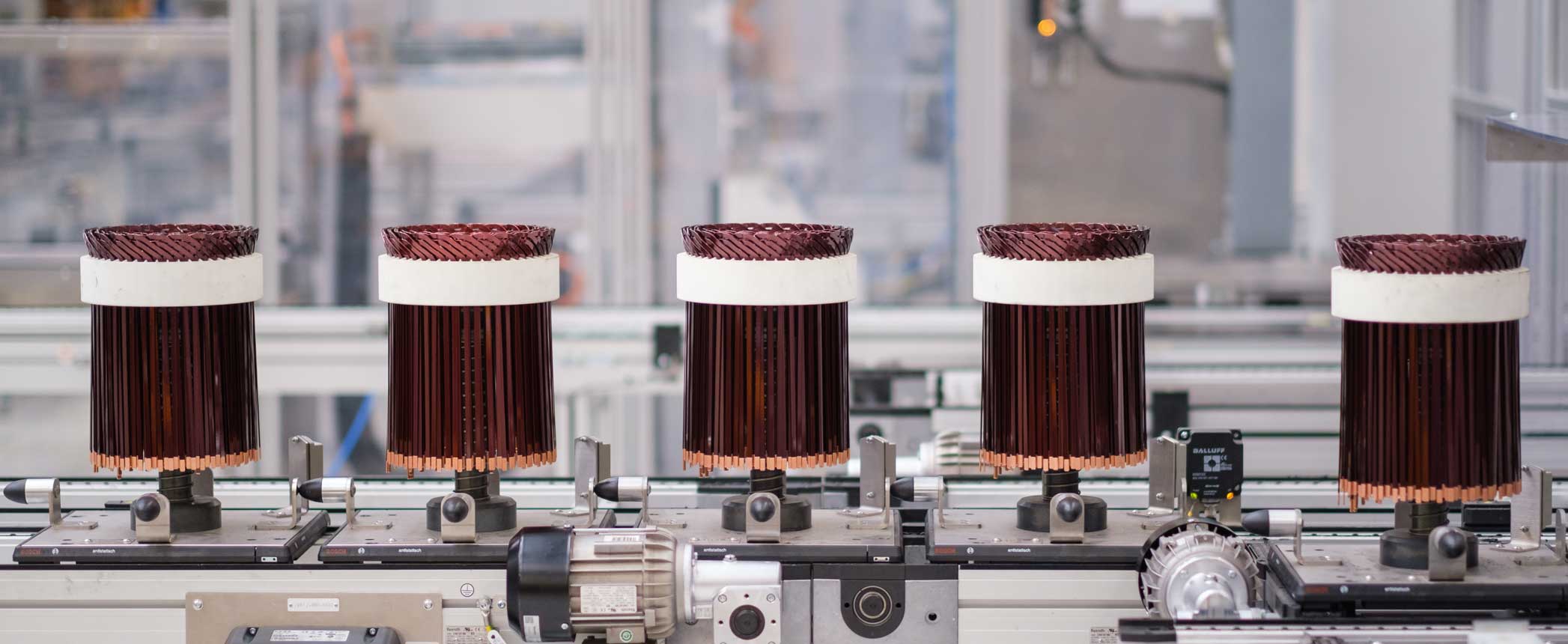

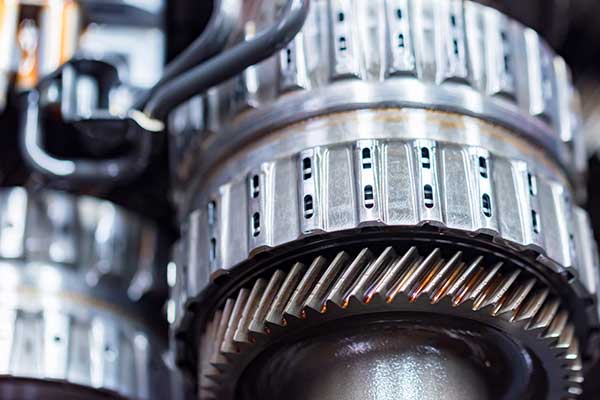

Trends to integrate motors with transmissions are motivating new expectations for transmission fluids with improved thermal properties and compatibility with copper, polyamides and various types of electrical insulation. Automakers and lubricant formulators are also focusing a lot on electrical conductivity and dielectric properties of fluids because of concerns about safety and discharge of static electricity.

Vehicle electrification presents new challenges for the handful of formulators developing automotive lubricants with the care of tailors who stitch bespoke suits to perfectly fit their clients. According to Michael Gahagan and Andy Jung, both working for Lubrizol Corp., several major trends in EV hardware are affecting formulation of new transmission fluids for next-generation EVs.

“The major trend with EVs is that of system integration, where components previously kept separate, such as e-motor and gear train, are being combined in the one unit,” Gahagan and Jung told Lubes’n’Greases via an email exchange. “Additionally there are higher voltages and, in some cases, higher localized temperatures in the vicinity of e-motor windings, especially where there is a high current draw. And we are seeing more plastics used in place of metal, particularly in bearing cages. Fluids need to be compatible with such plastic materials, in particular polyamides, which can be sensitive to lubricant formulation, magnet wire insulation and winding or slot-liner insulation.”

|

“Good fluid stability is especially important because the presence of sludge can inhibit the lubricant from removing heat effectively from hot immersed surfaces. There is more focus now on a fluid’s ability to act as a coolant for e-motors, and for this reason we have to optimize on the fluid’s viscosity characteristics as well, as understand the fluid density, heat capacity and thermal conductivity properties.”

|

Another significant change is the greater amount of copper (as much as 6 kilograms per vehicle), much of it in the form of electromagnet winding. For this reason, coupled with the high operating temperatures of e-motors, Gahagan and Jung are seeing more emphasis on the need for lubricants to protect the copper from corrosion. Transmission fluids are now being formulated to protect exposed copper immersed in the fluid and in the spaces above the fluid, where sensitive electrical lead frames may be present.

“‘Higher operating temperatures also put more thermal stress on the fluid and increase the potential for harmful oxidation reactions, and sludge or deposit formation from decomposed lubricant,” Gahagan and Jung added. “Good fluid stability is especially important because the presence of sludge can inhibit the lubricant from removing heat effectively from hot immersed surfaces. There is more focus now on a fluid’s ability to act as a coolant for e-motors, and for this reason we have to optimize on the fluid’s viscosity characteristics as well, as understand the fluid density, heat capacity and thermal conductivity properties.”

Gahagan and Jung discussed another trend related to vehicle electrification. “There is much more focus on electrical conductivity of fluids now than in the past, for example a decade ago.” Electrical conductivity refers to the ease with which a material conducts electricity. For fluids, more numerous and mobile ions and other charge carriers, for example polar molecules, mean greater electrical conductivity.

They continued, “The automotive OEMs have a focus on the electrical properties of the fluids and on the ASTM methods used in laboratory testing. The International Standards Organization has a standard for electrically propelled road vehicles as part of their safety specifications: ISO 6469-3 standard for electrical safety specifies requirements for electric circuits of EV propulsion systems for the protection of persons against electric shock and thermal incidents.

“‘There was a concern that if the electrical conductivity of oil was very high, there could be a risk of electrical shock. The factors affecting this property are better understood nowadays based on the research work we have done. Our investigation shows the lubricating fluids to be very good electrical insulators. The impact of oil aging, for example after being oxidized or in service, on conductivity is a more recent focus of our research.”

According to Gahagan and Jung, one of their current technical challenges is to measure the electrical properties, especially the electrical conductivity, of lubricating fluids. They are modifying existing ASTM and International Electrotechnical Commission test procedures for transformer oils and other insulating fluids. For example, ASTM D1169 was originally intended for evaluating new and in-service electrical insulating fluids in contact with electrical apparatus.

“Our testing to date in terms of electrical properties shows lubricating fluids to be safe for hybrids and EVs according to standards for conductivity. Our testing in actual gearboxes for electrified vehicles, for example to ISO 6469-3 standard, shows the fluids tested to be desirably orders of magnitude below the maximum specified limit. We have measured leakage currents in both laboratory apparatus as well as in actual gearboxes. Lubricating oils are extremely poor electrical conductors and so are very good at preventing the leakage of electrical current compared with other materials such as metals,” they reported.

“Electrical conductivity is a significant factor in lubricant formulation decisions such as choice of base stocks and additives for EV fluids. We can formulate to lower (or raise) the electrical conductivity by suitable base stock and additive selection. This has been a significant factor for our development of fluid technology for EVs, and we often demonstrate this in tests.”

The Lubrizol researchers expect that lubricating transmission and motor oils with low conductivities will be able to dissipate static electricity build-up that can affect hardware such as bearings and filters. When two dissimilar materials in contact undergo relative motion, electrons transfer from one material to the other. Excess electrons move through a conductor to electrical ground and dissipate harmlessly, but they accumulate as static charge in an insulator discharge releases electrons, often creating a spark and audible noise.

|

“Our testing shows that lubricant permittivity is amongst the lower values obtainable for common materials. This has alleviated concerns that the fluid may potentially store electrical charge only to undesirably release such a charge.”

— Michael Gahagan & Andy Jung, lubrizol

|

They explained, “Electrostatic charge generation can occur in fluid systems as a result of friction between the fluid and system components. The magnitude of this depends on many interrelated factors, including the equipment design. It can occur during filtration of hydraulic and lubricating oils but is best known in diesel and gasoline fuels, and is less of a concern in lubricating oils since the additives present in the fluids help dissipate the electrical charge built up in this way. [Transfer hoses at gasoline stations are attached to grounded conductors, and aviation fuels are formulated with anti-static additives, to prevent static discharge that could ignite flammable fuel vapors.]

“Our research has been on how our lubricating fluid technology can suppress and quench electrical discharge. There is one test, ASTM D924 [test] for permittivity, which is the ability of a material to store electrical charge [similar to a capacitor]. And three tests – namely ASTM D1816, ASTM D877, and IEC 60156 – which find favor more by the European OEMs, are available for the dielectric strength of a fluid. These methods deliberately develop electrical charges leading to eventual electrostatic discharge, such as a spark.

“Our testing shows that lubricant permittivity is amongst the lower values obtainable for common materials. This has alleviated concerns that the fluid may potentially store electrical charge only to undesirably release such a charge,” they reported.

While low values of conductivity and permittivity are ideal under many conditions, other situations can be more complex. If the dielectric strength of a material is low, a strong enough electric field can force electrons to break free from molecules, which collide with other molecules and dislodge more electrons in a cascade. The result is dielectric breakdown, where an insulator temporarily behaves like a conductor and discharges electrons, often with a visible spark and audible noise.

In hydraulics and lubricated industrial systems, flow electrification results from friction among molecules within moving fluids and at their interfaces with pipes, hoses, pumps, filter pores, and air and other gases, say in turbulent flow or a reservoir. Fluids with relatively low conductivities and high dielectric strengths are prone to charge accumulation and electrostatic discharge that causes fluid degradation, leading to varnish and sludge formation and etching or pitting of component surfaces.

Furthermore, electrons migrate, moving along conductive surfaces such as pipes, and undergo charge relaxation, redistributing themselves back into the material where they were removed by friction. Speeds of these various processes depend on factors such as conductivity and dielectric characteristics of the fluid and other materials, flow rate and temperature – any of which may alleviate or exacerbate charge accumulation and discharge.

Remedies include grounding equipment, placing conductive mesh downstream of filters in circulating systems, changing fluid temperature and flow rate, redesigning equipment, removing entrained air and reformulating lubricants.

According to Behrouz Abedian, an associate professor in the Department of Mechanical Engineering at Tufts University in Medford, Massachusetts, United States, temperature affects flow electrification of engine oils and static charge accumulation during cold starts of vehicles.

“In dielectric liquids such as motor oils, the time that an isolated liquid mass can remain electrified is known as its electrical relaxation time,” he explained. “It is inversely proportional to electrical conductivity. For any lubricating oil at very low temperatures during a cold start, its conductivity is low and its relaxation is relatively slow, so electrified oil remains charged. As oil temperature begins to rise and oil starts to flow, it can lead to charge accumulation in the circulating system and potential for damage from static discharge. After the oil reaches operating temperature, its electrical conductivity is higher, and its relaxation is faster, so charge dissipates, provided fluid is in contact with grounded component parts.”

|

“As advanced engines continue to include more electronics, new research is needed to shed light on temperature effects and other transitory behavior related to electrostatic charging and static dissipation in automotive systems.”

— Behrouz Abedian, Tufts University

|

Yet another temperature effect involves components such as filters, he said. “Changes in temperature during startup can also affect formation of a voltage spike and an electrostatic charge surge downstream of a filter. The severity of this behavior is influenced by a wide range of variables, such as the size and arrangements of the compartments in the circulation system, the electrical conductivity of the circulating oil, the types of filters and pumps, the flow-volume rate, etc. A complete system analysis is needed to assess the practical significance of this behavior for specific engines and operating conditions.

“As advanced engines continue to include more electronics, new research is needed to shed light on temperature effects and other transitory behavior related to electrostatic charging and static dissipation in automotive systems.”