To help you understand the basics of the lubricants industry, from base oil groups to additive treat rates, first let’s ask where most lubricant come from – crude oil.

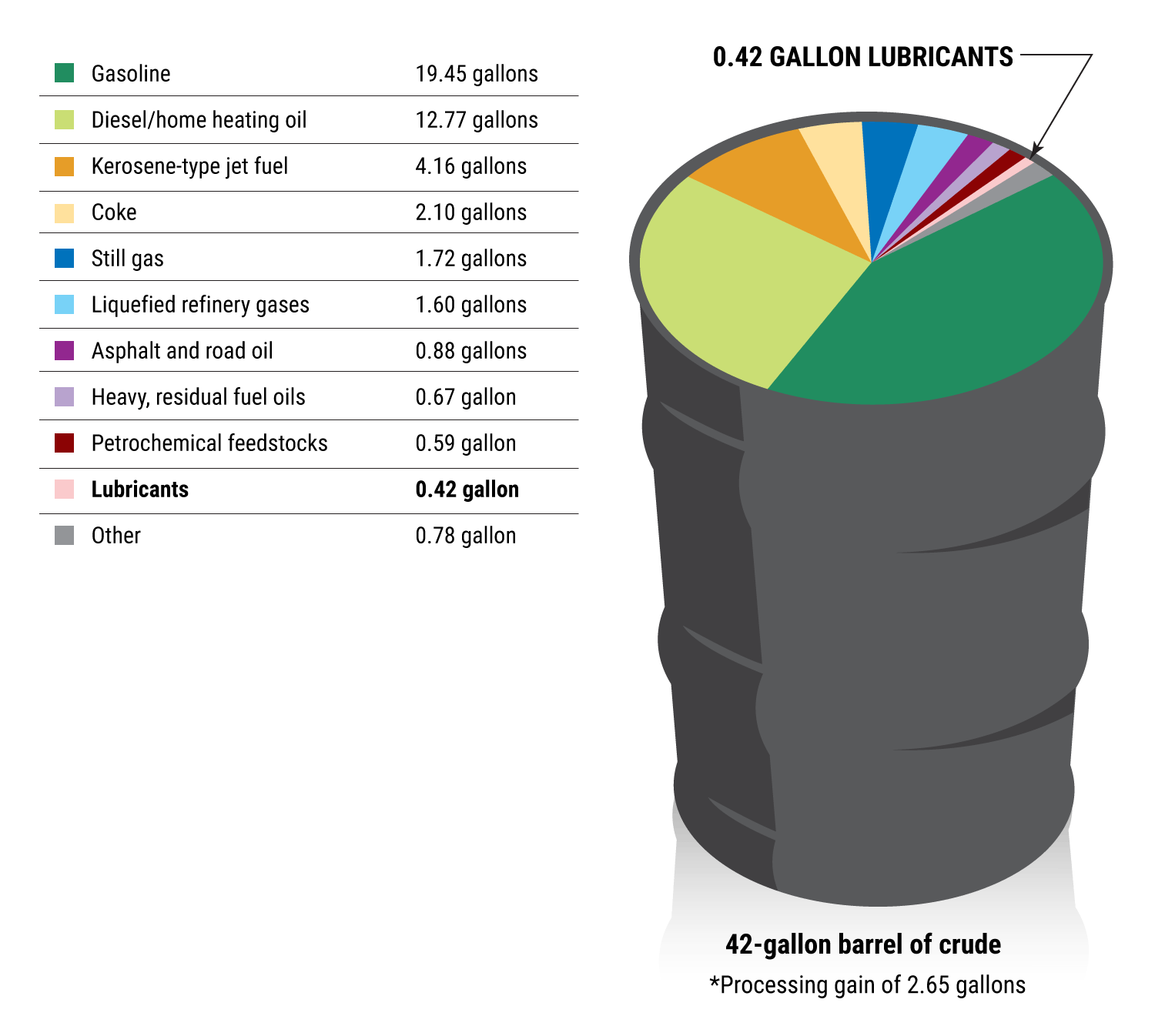

What’s in a Barrel of Oil?

A 42-gallon barrel of crude oil (approximately 0.14 metric tons) outputs nearly 45 gallons of products, 3 gallons more than the input due to what’s known as processing gain, whereby the products have a lower specific gravity than the crude. Overshadowed by higher-value products like gasoline, jet fuel and diesel, just a small portion of a barrel is allocated to the production of base oil, the main component of lubricant.

How Much Base Oil is in a Barrel of Crude?

Base Stocks

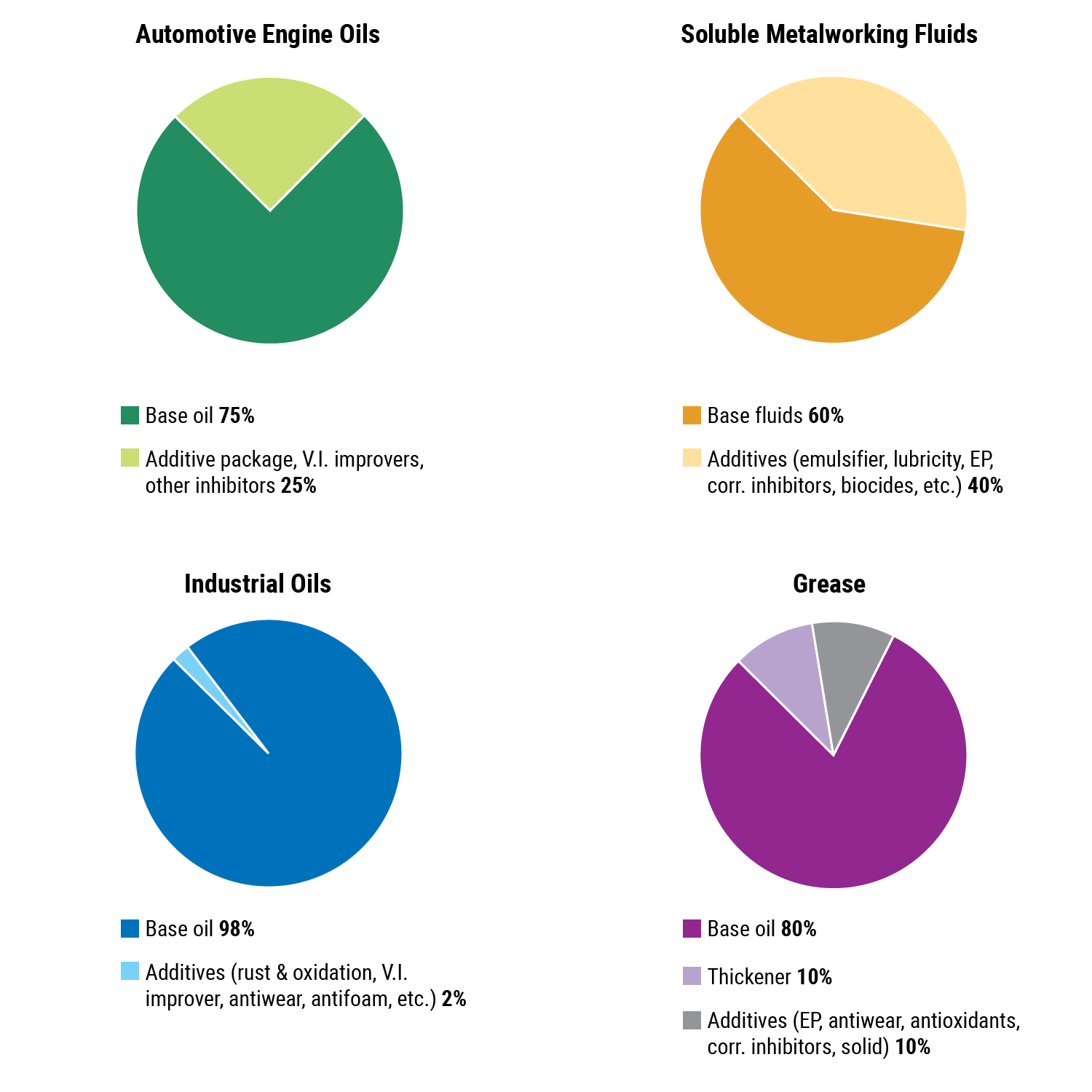

Base oil makes the finished lubricants world go round, making up anywhere from 60%–98% of typical formulations. Created nearly 30 years ago, the American Petroleum Institute’s base oil groups are the global standard and were established largely to aid in base oil interchange for automotive engine oils.

In addition to the sulfur and saturates content and viscosity index that define the API group, base stock marketers often provide data on several other parameters, like flash and pour points, viscosity and color. With modern base stocks falling more along a spectrum rather than into distinct categories, some industry players believe the system is now outdated and needs to be updated.

Additives

Additives comprise varying proportions of finished lubricants. Metalworking fluids tend to contain the most, at 10%–40% by volume of the formulated product. Automotive engine oils follow with 15%–25% additives and grease contains anywhere from 0%–10%. Industrial oils rely heavily on the quality of their base oil, with many using 2% additives at the most.

Additive Treat Levels