Understanding the differences between Group I, Group II, Group III and naphthenic base oils is essential for lubricant formulation, industrial performance and cost optimization. Each base oil group is defined by its refining process, chemical composition, viscosity index and performance characteristics.

Group I Base Oils (Solvent-Refined Mineral Oils)

Group I base oil refining begins with vacuum distillation, separating heavy hydrocarbons from lighter fractions. The heavy cut undergoes solvent extraction to remove aromatic compounds and impurities, followed by solvent dewaxing to eliminate long-chain wax molecules that negatively affect low-temperature performance.

After dewaxing, the oil is hydrofinished under hydrogen-rich, high-temperature and high-pressure conditions to saturate unsaturated molecules and neutralize free radicals. This conventional solvent-refining pathway produces classic Group I base stocks, including solvent neutrals and bright stock.

Some refineries use alternative hydrotreating and catalytic dewaxing methods—similar to Group II processing—especially when handling naphthenic crude feedstocks.

Characteristics

- Less than 90% saturates

- More than 0.03% sulfur

- Viscosity Index (VI): 80–120

- Operating temperature range: 0 to 65.5 °C

- Simplest refining process means lowest-cost

Group I oils remain widely used in industrial lubricants, marine oils, and applications where solvency and cost efficiency are prioritized over high oxidation stability.

Group II (Hydroprocessed Base Oils)

Group II base oil production replaces solvent extraction with advanced hydroprocessing. Heavy vacuum-distillate fractions are sent to a hydrocracker, where hydrogen at elevated pressure and temperature converts aromatics and waxes into stable paraffinic and naphthenic hydrocarbons.

Instead of solvent dewaxing, Group II oils use:

- Catalytic dewaxing, which cracks wax into lighter products (lower yield), or

- Wax isomerization, which converts wax into branched paraffins, improving yield and cold-flow properties.

A final hydrofinishing step saturates remaining unsaturated molecules and removes reactive compounds.

Characteristics

- More than 90% saturates

- Less than 0.03% sulfur

- Viscosity Index: 80–120

- Improved oxidative and thermal stability versus Group I

- Higher capital investment due to hydrocrackers

Group II oils offer a more uniform, stable product and are widely used in automotive, hydraulic, and industrial lubricants.

Group III (Severely Hydrocracked/Synthetic-Like Oils)

Group III base oils are manufactured using severe hydrocracking, catalytic dewaxing, and hydrofinishing applied to high-quality vacuum-distillate feedstocks. Under extreme pressure and temperature, hydrocracking converts aromatics and wax into highly saturated paraffinic structures, raising the viscosity index above 120.

Catalytic dewaxing converts wax into iso-paraffins instead of removing it, preserving yield while significantly improving low-temperature flow. Final hydrofinishing eliminates residual heteroatoms and unsaturated compounds, resulting in water-white clarity and excellent oxidative stability.

Characteristics

- At least 90% saturates

- Maximum 0.03% sulfur

- Viscosity Index: >120

- Synthetic-like performance while remaining API-classified mineral oil

Group III base oils often match or exceed PAO performance in many applications and are widely used in premium automotive and industrial lubricants.

Naphthenics

Naphthenic base oil refining starts with vacuum distillation of atmospheric residue to obtain lubricant fractions. Because naphthenic crudes contain minimal linear paraffins, dewaxing is usually unnecessary, simplifying processing.

The distillate undergoes solvent extraction or hydrotreating to remove aromatics, sulfur, and nitrogen compounds, followed by hydrofinishing to improve oxidation resistance and color stability.

Characteristics

- Low pour points (often below –70 °C)

- Intermediate viscosity index

- High natural solvency

- Excellent additive and contaminant solubility

These properties make naphthenic oils ideal for transformer oils, process oils, metalworking fluids, rubber oils, and greases. Fewer refining steps also make them cost-effective where high VI is not required.

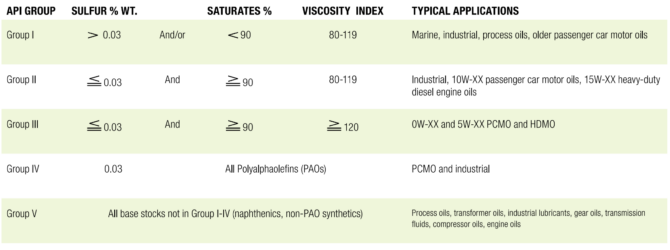

API Definitions

What are Group II+ and III+?

Industry-established “categories” originally developed to describe base oil suitable for SAE 10W-XX and 5W-XX multi- grade motor oil blending. They are marketing terms, not official API definitions.

• Group II+ is generally recognized as referring to Group II oils with viscosity index of 112 to 119 and Group III+ as referring to Group III oils with VI of 130 or greater.

• Viscosity grades are tailored to making passenger car motor oils.

• More recently, companies have begun marketing Group I+. The same principal of higher-end viscosity index applies.