Usage of titanium is rising fast in a variety of applications. High strength-to-density ratios and corrosion resistance are making the element popular in industries ranging from aerospace and defense to electric vehicles, energy and chemicals processing.

Of course, this also means increases in metalworking processes that produce the titanium materials and components used in those applications – processes that industry continues to hone in the ongoing effort to improve quality and efficiency.

Drilling is one of those processes, and a combined team of researchers from industrial lubricant supplier Quaker Houghton and Canada’s Windsor University are among those studying how drilling fluids can contribute to it. At an industry event earlier this year, a member from that team reported the choice of lubricity additives used in fluids can impact the outcome of drilling operations, but also that performance of those additives can vary greatly depending on operating conditions.

“Lubricity may change dramatically with different lubricity additives and different metalworking fluid chemistries under different test conditions in titanium drilling,” Yixing (Philip) Zhao, senior manager and senior research scientist at Quaker Houghton’s Center for Innovation, said in May at the Society of Tribologists and Lubrication Engineers’ annual meeting and exhibition in Atlanta. The implication, he said, is that fluids used in titanium drilling should be formulated specifically for the applications in which they will be used.

At the Atlanta conference, Zhao recounted findings from tests conducted on three drilling fluids. The first, referred to as Product A and described as formulated with an “old” technology emulsifier and surfactant package, consisted of 46.2% mineral oil, 10% water and 17% chemical additives. In particular, Product A contained extreme pressure additives. Product B was polymer based, used second-generation emulsification technology and contained 34% mineral oil, 13% water and 35.8% additives, including polymer lubricity additives. Product C used third-generation emulsification technology and contained 50% mineral oil, 10% water and 17% additives including ester-based polymer for lubricity.

Testing Different Additives

To test performance, Zhao and his research partners used the fluids with a Windsor computer numerical controlled drill press, equipped with a 1.5 horsepower motor capable of drill speeds of 100 to 5,000 revolutions per minute. They used a 4 millimeter high-speed steel drill bit and drilled holes 6 mm deep in titanium G5, applying coolant at rates of 200 to 400 milliliters per minute using new nozzles and pressure of 6 pounds per square inch. Each test consisted of four sets of 20 holes, drilled at speeds of 300 to 2,500 rpm and feed rates of 0.01 to 0.4 mm per revolution.

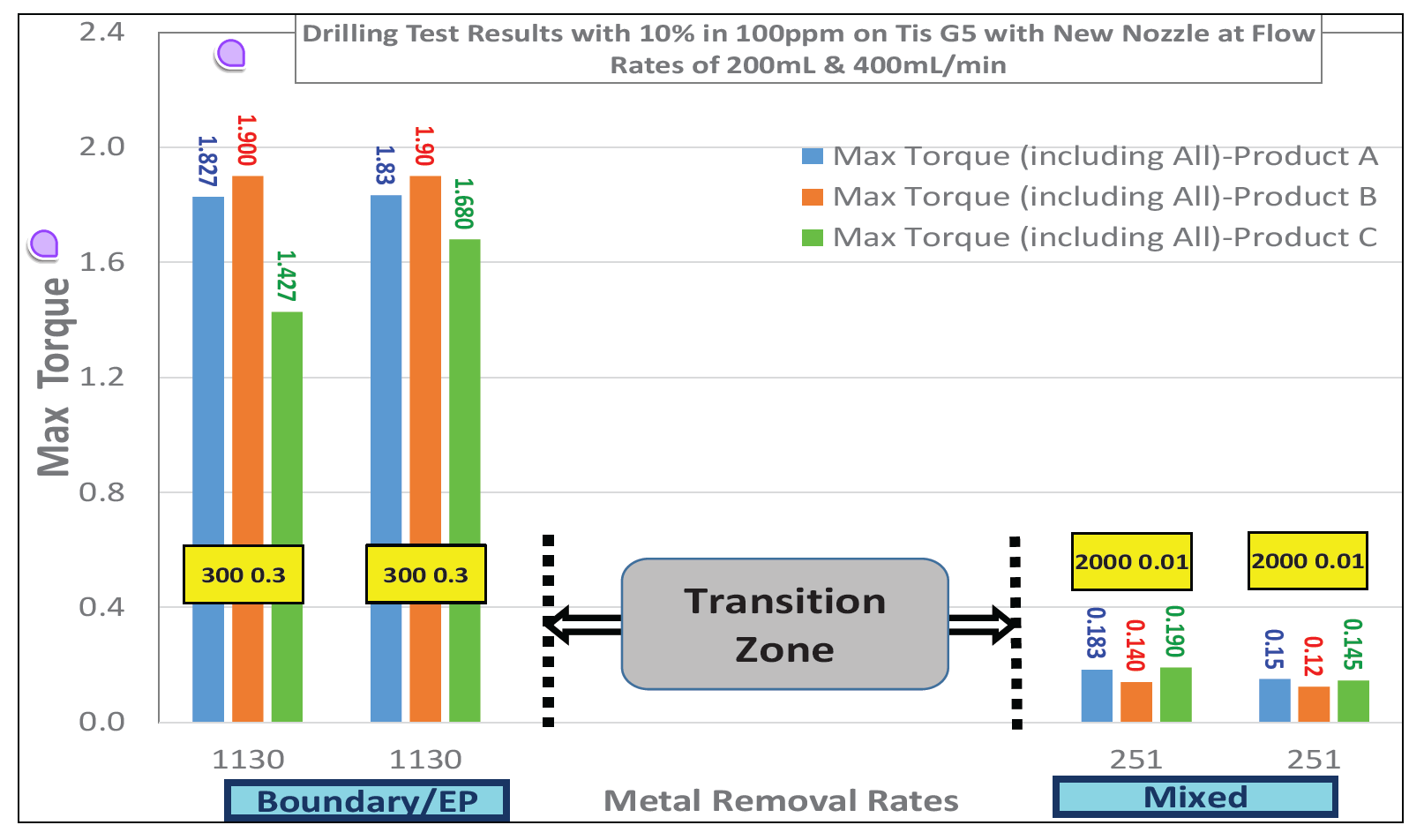

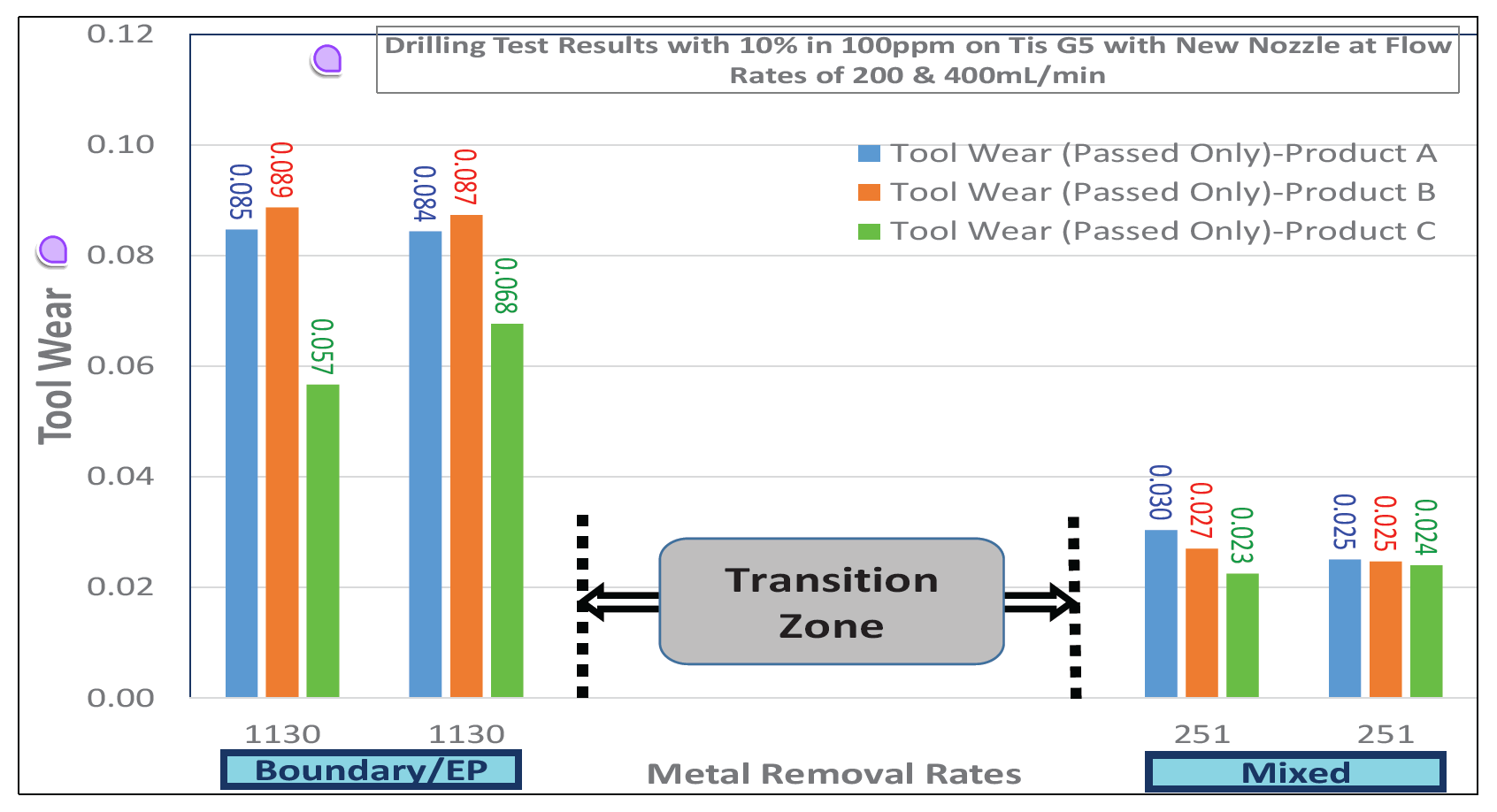

The researchers gauged fluid performance by two parameters – torque levels, or the amount of power required to turn the drill; and amounts of wear observed on the drill bit. In both cases, Zhao said, relative performance of the fluids varied depending on feed rates. Higher feed and metal removal rates resulted in higher torque levels, of course; almost by definition, drilling the hole faster requires the press to exert more pressure on the bit, and it is intuitive that this would cause more resistance to its turning.

As shown in Figure 1, Product A had better lubricity – yielded lower torque – than Product B when the drill bit was turning slower (300 rpm) but penetrating the hole faster (0.3 mm/revolution) but Product B had better lubricity at higher speed (2,000 rpm) and lower feed rate (0.01 mm/rev). Product C performed best at low speed-fast feed but was worst or second-worst to Product A at high speed-slow feed.

Figure 1.

Zhao explained that this is possible because the lubrication dynamic changed between those sets of conditions. At the higher feed rate, the bit and titanium block were in boundary lubrication, where force is great enough that the lubricating film between surfaces disappears and the surfaces come into contact. Under such circumstances, the fluid only provides lubrication if additives adhere to one or both surfaces, creating a layer that protects against wear. This is exactly what extreme pressure additives do.

At the experiment’s lower feed rates, Zhao said, the system entered the mixed lubrication zone; a film of lubricant had started to form between bit and block – the film that would characterize the hydrodynamic/elastohydrodynamic zone – but some metal-to-metal contact still exists, so this is an intermediary zone. Here the extreme pressure additives in Product A were less of an advantage, and the benefits of Product B’s polymer lubricity agent come into play.

Figure 2.

“In the boundary/EP zone, Product A has better lubricity than Product B,” Zhao said, “but under mixed lubrication, Product A has worse lubricity than Product B.”

As shown in Figure 2, wear protection performance corresponded to the lubricity results. At the higher feed rate, “In boundary/EP, Product A has better life than Product B,” Zhao concluded, “while in mixed/elastohydrodynamic Product A has worse life than Product B. Product C has better life than both Product A and Product B in both boundary/EP and mixed/elastohydrodynamic.”

Cooling and Chips

The researchers also compared cooling performance of the test products as well as the effects of different fluids and operating conditions on parameters such as chip generation and handling. The size of chips from the workpiece can vary significantly, from small granular particles to long, stringy shavings. The former are preferable because they are less likely to clog or cause other problems when ejected, Zhao said.

To analyze these parameters of performance, the researchers chose more challenging conditions – meaning high drill speed and high feed rate. First they compared differences in chip generation for two combinations of operating conditions using products A and B. At drill speed of 300 rpm and a feed rate of 0.4 mm/revolution, both coolants generated small granular chips – the desired variety. At 2,000 rpm and a feed rate of 0.01 mm/revolution, the chips became long and stringy.

Operation became more challenging when both speed and feed rate were increased. Zhao showed photos of another comparison of drilling at 3,200 rpm and 1,600 rpm, both at a feed rate of 0.05 mm/second. After 1,600 rpm, the drill bit showed slight wear and little adhesion of titanium waste. After 3,200 rpm the bit was fractured and had a large amount of titanium adhesion.

“High speed plus high feed rates dramatically increased temperature and tool wear,” Zhao said, adding that adhesion is directly attributable to higher temperatures at the bit-workpiece interface.

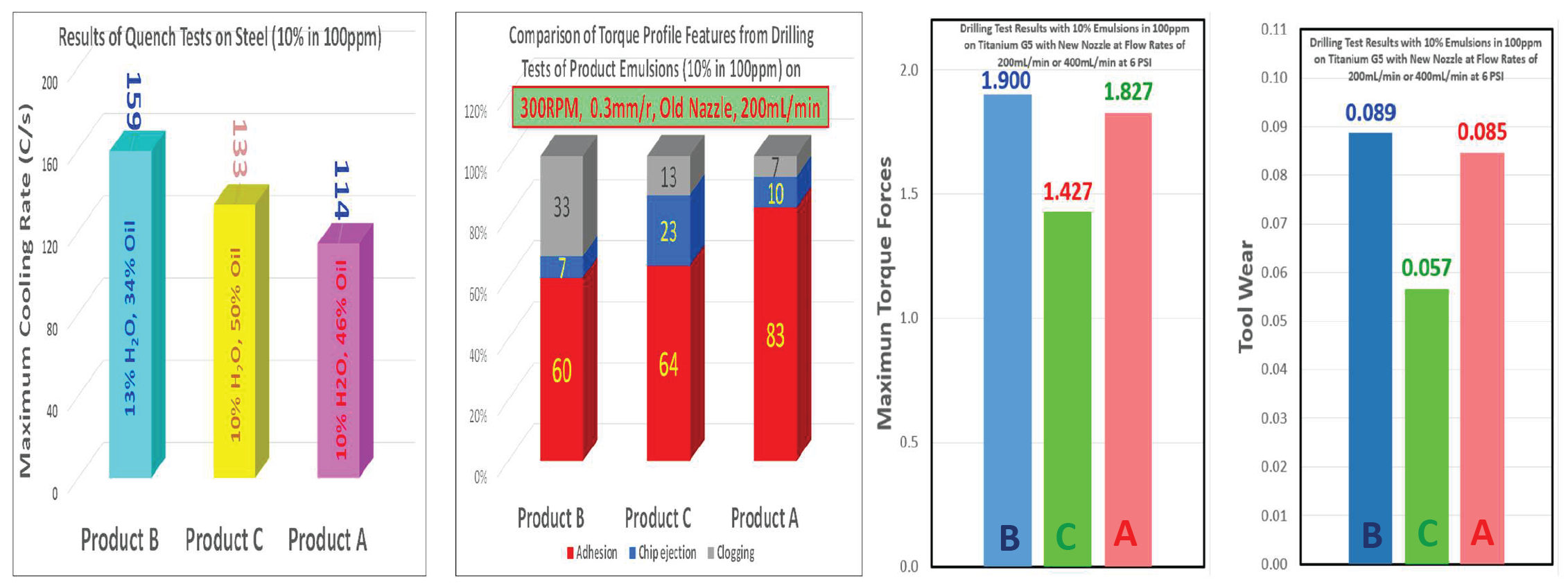

The researchers then compared cooling performance, chip management and wear prevention of the test products in a new round of titanium drillings at 300 rpm and 0.3 mm/revolution. As shown in Figure 3, Product B had the highest maximum cooling rate followed by Product C and Product A, Zhao said, suggesting that the portion of water in the formulation factored into those

results. Perhaps not surprisingly then, Product A had the greatest proportion of titanium adhesion. Product B had the lowest portion of adhesion – slightly less than Product C – but it had significantly more clogging than Product C. C had the highest rate of chip ejection, which is most desirable.

When it came to torque levels and tool wear, though, Product A outperformed Product B, Zhao said, because the extreme pressure in A was activated more than that in B. Product C performed better than either of the other two products in both lubricity and wear prevention.

More Additives

The researchers then broadened the investigation by adding 11 more fluids, each formulated with different additives. These included four more made with polymeric esters, one containing a high molecular weight polyalkylene glycol, one made with a simple ester, one with a long-chain fatty acid and four made with phosphate esters. They ran tests at two extremes of conditions – at 2,500 rpm and a feed rate of 0.01 mm/revolution and at 300 rpm and 0.4 mm/revolution.

Each was scored for lubrication efficiency, compared to the original Product C, which was indexed with a rating of 100. The new polymeric ester fluids performed best in high speed, low feed conditions. Those four fluids were among the top six performers in those conditions, all scoring between 114 and 125. The fourth phosphate ester scored best by far – 152 – and the high molecular weight PAG tied for third best at 121. Three fluids scored lower than Product C: two of the phosphate esters, the simple ester and the long-chain fatty acid, which was worst at 78.

Figure 3. Comparison of Cooling Rates, Adhesion, Drilling Torque Forces and Tool Wears

In the slower speed, faster feed portion of the test, the fourth phosphate ester was again a top performer, just a point behind one of the new polymeric ester fluids (the worst performer of that group at high speed, slow feed) at 117. Otherwise the polymeric esters and phosphate esters generally flip-flopped from the previous conditions. Two of the other three polymeric esters scored below 100, while all of the phosphate esters scored at least 107. The long-chain fatty acid was again in the rear, though not as far behind this time at 95.

The researchers also calculated torque profiles of all 12 fluids at for both conditions. Results were generally significantly worse at low speed and fast feed, with most of the fluids allowing significant adhesion in those conditions and significantly less allowed at high speed, slow feed. Within each set of conditions, though, performance varied widely with few clear patterns. The phosphate ester fluids as a group performed better than the polymeric esters at low speed and fast feed, but that pattern faded at high speed and slow feed.

Altogether the researchers analyzed drilling profiles of approximately 1,900 holes during the study, Zhao said, adding that the lessons can be leaned on to select formulations that meet the needs of metalworking applications.

“With these results and learnings, we can select different lubricity additives to build lube packages for specific lubrication regimes – or for broader lubrication conditions,” he said.

Zhao repeated the take-away that relative lubricity performance of different additive chemistries can vary under different operating conditions. He also inferred that Quaker Houghton will further explore capabilities of ester-based polymer lubricity additives.

Tim Sullivan is Executive Editor of Lubes’n’Greases. Contact him at Tim@LubesnGreases.com