An independent research institute in Germany announced in March of this year that it has developed two real-time methods for measuring the homogeneity of lubricating greases during the production process. What do these new methods entail, and how might they change the quality control game for grease makers around the globe?

What Is Grease Homogeneity?

Very simply put, a homogenous grease is one that has a uniform structure or composition throughout. In other words, the various components that make up the grease—in essence, the base oil, the additives and the thickener—are very well mixed.

While it may seem obvious why it is important for a lubricating grease to be adequately homogenized, it is worth taking the time to explicitly state the merits of homogeneity.

According to Probst & Class GmbH—a manufacturer of machines for industrial processing based in Rastatt, Germany, and commonly referred to as PUC—grease homogeneity is vital to performance. “In order to meet the stringent requirements of modern industry, a lubricating grease must have the same concentration as the average value for the batch, down to areas as small as about a thousandth of a millimeter,” the company said.

What’s more, PUC explained that the homogeneity of a lubricating grease can greatly affect the physical properties of the grease. These properties include but are not limited to the following:

- Penetration and stiffness.

- Oil separation.

- Fine dispersion.

Because homogeneity can affect these various grease properties, it goes to reason that a grease with poor homogeneity will likely not perform as well as it should in its respective application. This could potentially result in costly damage to equipment as well as increased downtime for equipment maintenance and repairs.

How Is Grease Homogeneity Measured?

While it is clear why grease homogeneity is vital, what is less apparent is how homogeneity in lubricating greases is actually determined. Fortunately, researchers at OWI Science for Fuels GmbH have come up with a way to both quickly and accurately measure the homogeneity of some lubricating greases during the production process.

OWI Science for Fuels GmbH is an independent, non-profit research institute based in Herzogenrath, Germany. The institute works in cooperation with industrial partners as well as other research institutes, and its mission is to develop concepts and technologies for the energy-efficient use of both conventional and alternative fuels. OWI is closely affiliated with RWTH Aachen University, and it considers itself a mediator between fundamental research and application. OWI works on projects that are financed using public funds as well as by industrial research agreements. The institute’s clients include manufacturers of domestic heating systems, companies in the automotive supply industry, companies in the petroleum industry and companies from the industrial furnace engineering industry, among others.

The homogenization of the grease is one of the final steps in the production process for lubricating greases. In this process, a homogeneous distribution of the base oil, the thickener and the additives within the grease can be achieved by mechanically mixing all the components together. As of right now, there do exist some random checks that can be used to determine the homogeneity of the greases, OWI said, but for the most part these methods have proven to be both time consuming and expensive.

“Automation of homogenization has not been possible until now because suitable measurement parameters and methods were lacking,” OWI said in a March 14 press release.

Researchers at OWI have identified two real-time methods of measurement that the institute has deemed suitable for determining the homogeneity of lubricating greases in the midst of the production process. For both a lithium soap grease as well as for a urea grease, the institute demonstrated that the methods of refractometry and FTIR-ATR spectrometry are suitable for assessing the homogeneity of the thickener structure of each grease. That is to say that these two methods allow for thorough analysis of the state of the grease structure during the homogenization process.

Refractometry is a technique that measures how light is refracted when it passes through a given substance, which in this case is a lithium soap or urea grease. The amount by which the light is refracted determines the refractive index, which is defined as the ratio of the velocity of light in air to the velocity of light in the grease being measured.

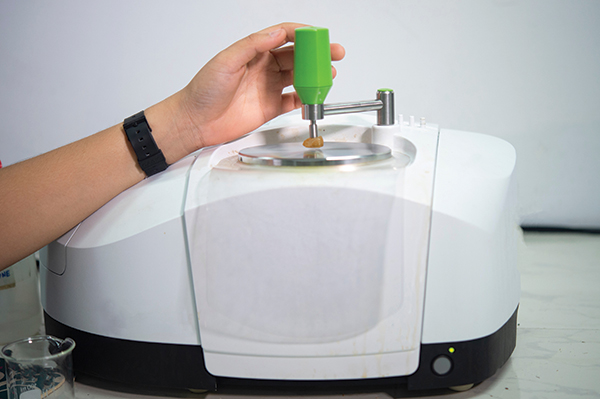

On the other hand, in FTIR-ATR spectrometry, infrared light passes through a crystal of a certain material and interacts with the respective sample, which is pressed onto the crystal. From this a spectrum can be obtained that shows all substance-specific characteristics. In this case, OWI researchers were paying particular attention to the strength of the absorption bands in the grease samples’ thickeners.

According to OWI, both methods can be integrated relatively “easily into the real-time monitoring of grease production.”

Each method can also provide valid results that can be obtained quickly. In fact, by using these measurement techniques, grease makers can obtain results in less than one minute, OWI said.

How Do These Methods Work?

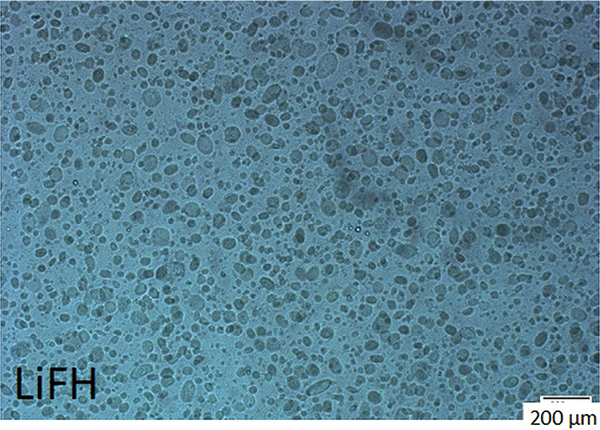

OWI explained in a press release that its investigations demonstrated that the thickener used to formulate the grease forms a network of fibers both in the lithium soap and in the urea grease. Furthermore, the institute stated that homogenization of the greases led to a refinement of this thickener structure.

“Measurement methods based on either the propagation of light waves or sound waves in the grease sample were tested and evaluated with respect to their potential to quantify grease homogeneity,” the institute said. “While measurement methods based on sound waves were not found to be suitable, a correlation between measurement signal and the homogeneity of the grease was shown for refractometry, which is the measurement of the refraction of light in the grease sample.”

Similarly, the measurement of the absorption of infrared light from FTIR-ATR spectrometry led to useful conclusions about the lithium soap and urea greases’ homogeneity as well.

“A significantly higher refractive index was measured for homogenized model greases than for the unhomogenized grease,” the institute explained. “The different degrees of homogenization of fat blends could also be differentiated by the refractive index.”

homogeneity © Rabbitmindphoto

For the grease homogeneity investigations performed by employing IR spectrometry, an FTIR spectrophotometer was used, and the attenuated total reflectance—also known as ATR—measurement setup was chosen, OWI said. By using this particular measurement method, the institute explained that it was evident that there were significant differences in the strength of the absorption bands of the respective thickener in the homogenized greases and the unhomogenized grease. This held true for both types of grease that were tested (lithium soap and urea).

Does One Method Reign Supreme?

OWI demonstrated that its two prospective methods of measuring grease homogeneity do in fact work. But which method—refractometry or FTIR-ATR spectrometry—worked best to determine grease homogeneity, if any?

When comparing the results of refractometry and FTIR-ATR spectrometry, OWI said that their research showed that “both parameters—the refractive index and the integral area of the thickener band—differentiate homogeneity with comparable sensitivity,” meaning that both methods can be used directly in lubricating grease production to accurately measure homogeneity.

Additionally, the institute concluded that for the grease homogenization process, both of the methods can be expected to result in a significant reduction in the time required to determine if the grease has been adequately homogenized. Because of this, these methods have proven themselves to be economically advantageous, as they enable more grease to be produced—and tested for homogeneity—in a considerably shorter period of time.

The institute also commented that these methods have not been used in this way until now.

OWI’s new methods are able to measure the homogeneity of the grease thickener, but are the methods useful to measure the homogeneity of the other components of the grease?

In a word, the answer is maybe.

The institute said that its “supplementary investigations of model greases with extreme pressure additives showed that a combination of refractometry and FTIR-ATR spectrometry could possibly also provide information about the distribution of the additives in the grease, provided that the additive has a significant influence on the refractive index.”

However, OWI maintained that further investigations into this are needed to make robust statements about the relationship between grease additives and the use of refractometry and FTIR-ATR spectrometry to measure their homogeneity.

“For the practical application of refractometry and FTIR-ATR spectrometry beyond the greases selected in the project,” the institute said, “it must be examined in the future whether they can also be applied to assess the homogenization of thickener structures of other types of grease.”

Sydney Moore is managing editor of Lubes’n’Greases magazine. Contact her at Sydney@LubesnGreases.com