Transmission Fluids

Back in the Twilight Zone (also known as 2020), I commented on a note that I had received from Allen Comfort. For those of you who are not aware, Allen is a research & development engineer with the United States Army Futures Command. This organization is aimed at modernizing the Army. In addition to the truly military aspects of warfare, it is involved in a number of other areas such as improving fuel efficiency and lubricant standards for combat and support vehicles.

Allen commented on my often-stated concern that transmission fluid requirements were so varied that it was seemingly impossible to create some order from the chaos of specifications. Specifically, he noted that he would love to see more standardization for both light- and heavy-duty transmission fluids. “I’ve heard the rationale that transmission designs are so unique that a special fluid is necessary, but I’m not sure I buy it. There has to be some room for standardization in these supposedly unique applications.”

There are others in the industry who have expressed concerns about this issue, so I think it’s time for me to try to answer or at least clarify what’s going on and see if there can be some simplification that will make it possible to significantly reduce the number of transmission fluids in the marketplace.

Just for emphasis, Motor Information Systems’ Lubrication Recommendation Guide reports there are more than 100 different automatic transmission fluid specifications for today’s vehicle fleet.

Before we get to the subject of transmission fluids, we need to touch on the types of transmissions that are available in the marketplace. It’s hard to believe that with all of the specifications out there, there are really just four basic designs.

There are a number of websites and brochures that describe the four designs. You have probably heard the acronyms before, but in case you have missed one, here are the big four types of transmissions:

- Manual transmission. These are the most basic design in use. They are a series of gears linking the engine to the drive train. There is a clutch in between the engine and the transmission, which allows the driver to shift gears to meet the driving conditions. The earliest transmissions simply allowed the driver to change gears but lacked a mechanism to aid gear meshing. The introduction of synchromesh gears helped made the transition from one gear to another.

- Dual clutch transmission. This is a clever upgrade of the manual transmission. Basically, this type is a pair of transmissions that are controlled by a computer. DCTs shift gears very smoothly and efficiently. One transmission runs odd numbered gears (1, 3 and 5), and the other runs even numbered gears (2, 4 and 6). When the computer or driver determines that a shift is required, one clutch disengages while simultaneously engaging the other clutch. Fuel economy is improved, and the driver can choose to manually shift by overriding the computer.

- Continuously variable transmission. This design is actually very old. Would you believe that there is a sketch in one of Leonardo DaVinci’s notebooks that describes what is essentially a CVT? The concept is simple: two cones, one on the output shaft of the engine and the other on the driveline, are connected by either a chain or a belt. Depending on the speed and torque requirements, the connection belt finds the best position. Computers made this a reality in motor vehicles. They are limited to use in smaller engines and lighter weight. The biggest rap on them is that the driver can’t easily feel the CVT shift.

- Automatic transmission. This is the tried and true design that utilizes a combination of clutches and gears, which change according to speed and load requirements during driving. We all know these transmissions, as we have all probably driven at least one, if not more, vehicles with them. The first automatics were introduced in 1939 for the 1940 model year and came from GM, marketed as the Hydra-Matic Transmission. They had two or three forward gears as well as reverse. Today, there are versions with more than 10 gears.

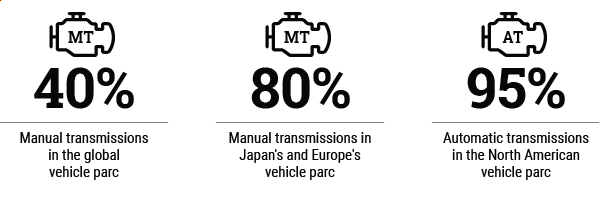

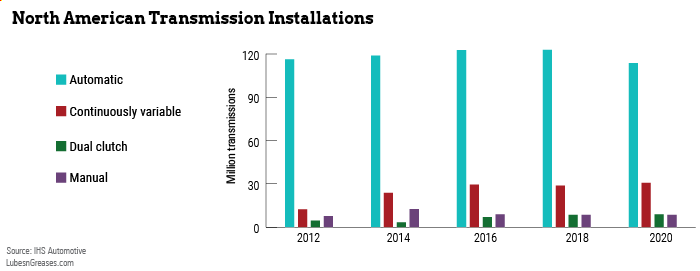

Globally, it is estimated that around 40% of vehicles have a manual transmission. The use of manual transmissions is most prevalent in Europe and Japan, where the mix is about 80% manual. That must come as a shock to North American owners, where about 95% of vehicles are equipped with an automatic transmission of some type.

So there are four transmission designs, but more than 100 specifications. Why is that? One point of view is that each transmission design team selected a fluid for evaluation and then specified it. This is not surprising, considering that many designers believe the fluid is an integral part of the whole.

The problem is that specifying a fluid would require adherence to Magnusson-Moss anti-trust regulations, which say that the fluid, being an integral part of the transmission, would need to be made available at no cost to the consumer.

A second possibility is that the transmission marketers (not necessarily the final marketer) wanted to be sure that only oils meeting the performance parameters their designers had built into the transmission were covered. They could avoid Magnusson-Moss by inserting the phrase “or equivalent” into the specification.

For engines, it’s easier. Back in the 1980s, GM engineers were still using 6 centipoise monograde engine oils for engine design work, even though GM was recommending SAE 5W-30 in order to capture fuel economy benefits. They were comfortable with monogrades and chose not to change.

Admittedly, the chemistry of transmission fluids does depend on transmission design. For example, in manual transmissions, an engine oil could suffice, but extra load-carrying capabilities are generally needed. With synchromesh gears, some additional corrosion inhibitor is important.

DCTs, CVTs and ATs all have requirements that are a bit different. One thing common among all transmission fluids is that oxidation resistance is crucial. This is because most modern transmissions don’t require fluid changes as often as engine oil; some not at all. This requires a very stable base oil. The industry has moved the composition of transmission fluids to include API Group II, Group II+ and API Group III base stocks as well as synthetics.

An additional need is for viscosity stability over a relatively wide temperature range. Cold starts and hot operating conditions demand a relatively flat temperature versus viscosity curve. Seal compatibility and corrosion resistance are both needed.

Of course, for all of the transmission manufacturers, specifications are designed for their transmissions without a thought to the end-use marketer. I was made aware of this by one fast oil change operator who had to find a specific fluid for a customer application. His only specified source was a dealer who was charging him a very high price for the product. As an alternate, he was using a fluid in his shop with a recommended booster that was “suitable for use” in the transmission. Not a good situation!

So all of this leads me to the suggestion that an industry group such as SAE’s Technical Committee 3 be tasked with establishing the need for a series of specifications for transmission fluids. The team would need to include transmission manufacturers, oil marketers and standards-setting body ASTM International.

There is currently a manual transmission standard in the April 2013 edition of API 1560, “Lubricant Service Designations for Automotive Manual Transmissions, Manual Transaxles, and Axles.” It’s not new and is actually a compilation of existing requirements from several years ago.

As I foresee it, there could be three new standards, one each for ATs, CVTs and DCTs. Standard tests could be developed to measure oxidation and shear stability—the usual and common tests for all types of transmission fluids. Beyond that, one or two tests would be needed to determine the performance specific to each transmission design.

Finally, at least two viscosity ranges as specified by transmission fluid designers would need to be included. That assumes that a viscosity classification system could be developed for transmission fluids. As you know, SAE J300 covers engine oils, but there is a separate gear oil system called SAE J306. Whether or not this could be adapted to transmission fluids is open for debate, but at least it’s a starting point.

The challenge is huge, but the benefits to the oil marketers, oil users, transmission designers and hardware marketers could be of great benefit to the industry. At any rate, it seems like there is job security for the folks involved, since this could very well be epic in size and duration. I sure would like to see it happen.

Steve Swedberg is an industry consultant with over 40 years experience in lubricants, most notably with Pennzoil and Chevron Oronite. He is a longtime member of the American Chemical Society, ASTM International and SAE International, where he was chairman of Technical Committee 1 on automotive engine oils. He can be reached at steveswedberg@cox.net.