Biofuels are one key to reducing greenhouse gas emissions from the shipping supply chain, and initial trials highlight the importance of testing to understand how the fuels impact wear and cylinder combustion condition that may require adjustments in cylinder lubricant oil usage, a speaker said at an online webinar last week.

The International Maritime Organization greenhouse gas strategy calls for reducing emissions from shipping by 50% by 2050 and phasing out of such emissions from international shipping as soon as possible. It also calls for reducing carbon intensity from shipping by 40% by 2030 and by 70% by 2050.

Although alternative ship fuels are under development, biofuels are the main contender for reducing shipping decarbonization in the very short term, Naeem Javaid, global operations manager for fuel oil bunker analysis advisory service at Lloyd’s Register Global Technology Center, said Sept. 1 during a webinar, “How heavy fuel and biofuel mixes impact marine lubrication,” hosted by Riviera Maritime Media. Lloyd’s Register is a global professional services company specializing in engineering and technology for the maritime industry.

“Functionally they are equivalent to petroleum-derived fuels and compatible with existing machinery and infrastructure,” he said. “We call it the drop-in fuels, because there’s no need for any significant change in technology on ships.” There’s also no need to adjust engine settings, he added.

Although the shipping industry so far doesn’t have enough experience using biofuels to draw anything conclusively about its impacts on marine engine lubrication, some initial observations can be made, according to Javaid. “One thing we can learn from the automotive industry is that you had to change your oil more frequently,” he said. “It was getting interrupted by the mixing of biofuels with lube oils.”

He noted that lubricant oil mixed with a high proportion of biofuel blends in medium speed engines may be more prone to oxidation, soot and deposit formation, and wear.

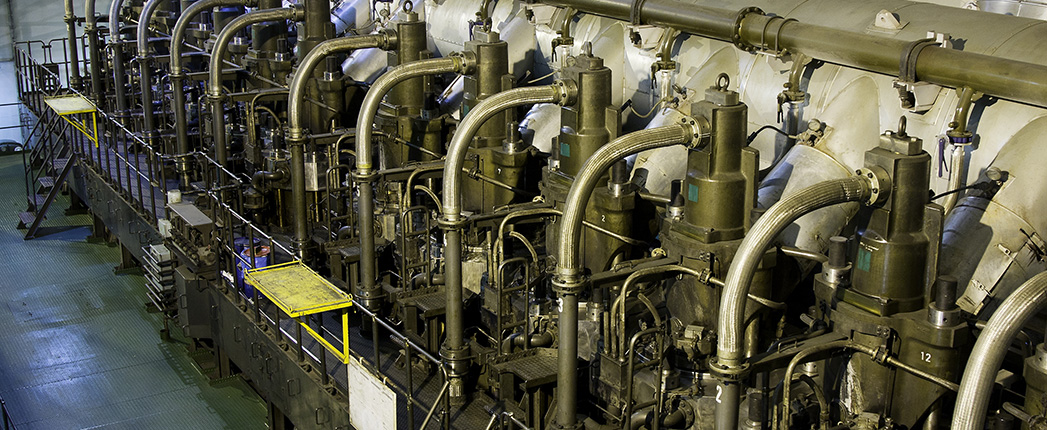

For two-stroke engines, taking regular scrape-down samples is important to evaluate the wear and cylinder combustion condition during biofuel use, he said.

Cylinder oil provides lubrication for large marine two-stroke engines. The oil protects the engine’s combustion section from damage that could stem from mechanical wear or cold corrosion. Scrape-down samples are collected from each cylinder and analyzed as part of preventive maintenance. However, in the case of an initial trial-use of biofuel in a ship engine, he recommended allowing the engine time to get settled down – generally two to three days of operation – before taking the samples to get more insight on the engine’s lubrication.

“We didn’t see any specific compelling evidence you have to increase the lubrication,” he said of trials using biofuels in ship engines. “Some trials showed that by increasing a little bit of lubrication you were able to maintain the same condition of the equipment.” The conclusion from the trial was a recommendation to adjust the cylinder lubricant oil feed rate accordingly during and after changing to biofuel after the nominal two-two-period.

Javaid said that short-term trials also suggest that biofuels, especially the B20 variant, may require cylinder oil with a base number higher than 40. B20 is fuel with 20% of its content derived from plant oils. He emphasized that using a cylinder oil with higher base number was recommended for a short-term trial and may not be appropriate for longer-term use. “Please contact engine manufacturers for specific guidelines,” he added.