Valvoline continues to cement its status as a leading provider of greases and is proud to have recently received accreditation for its new state-of-the-art laboratory and research and development facility in Krusevac, Serbia.

After completing a successful audit late last year, the facility has now been issued with SRPS ISO/IEC 17025:2017, demonstrating its continued high standards in the testing and manufacture of greases.

“Grease remains a hugely important market for us and we see great growth potential,” says Ana Ivanovic, Valvoline’s Technology manager for greases. “Valvoline has a complete portfolio with over 100 proprietary grease formulations and provides a range of multipurpose and industry specific greases that are all ISO and DIN standards compliant, with all food grade greases NSF certified.”

Having bought Serbian lubricants blender FAM in 2019, Valvoline has continued to invest in extensive upgrades and expansion at the site, the company’s primary location for grease testing and production in Europe.

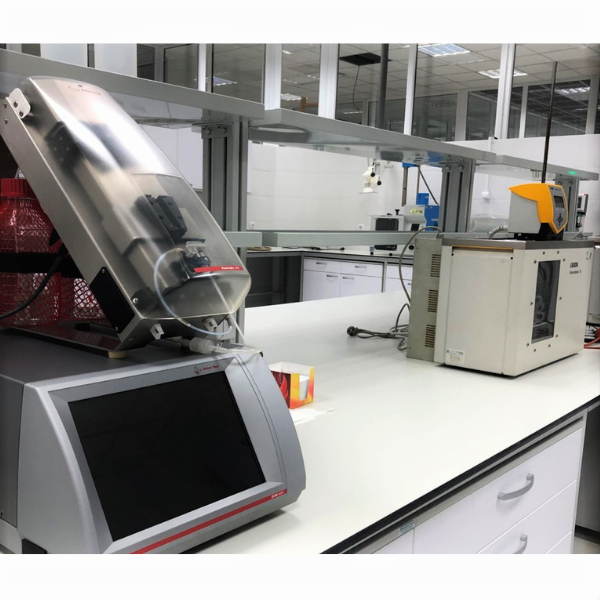

Work started on a new purpose-built laboratory just over a year ago and was completed in mid-2021. The past few months have seen Valvoline’s 14-strong team of engineers and technicians migrate to their new home.

With 950 square meters of dedicated laboratory and office space, it is 30% larger than the older site and allows for far more sampling, faster testing and improved feedback for the production teams, adds Ivanovic.

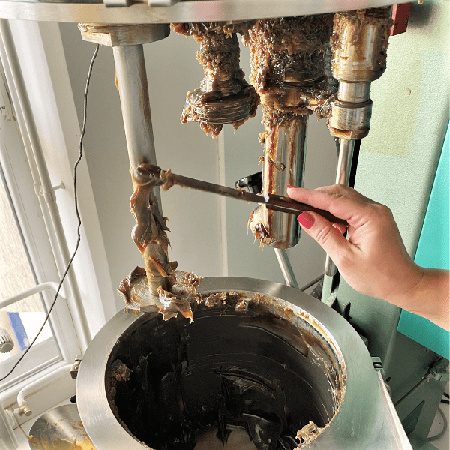

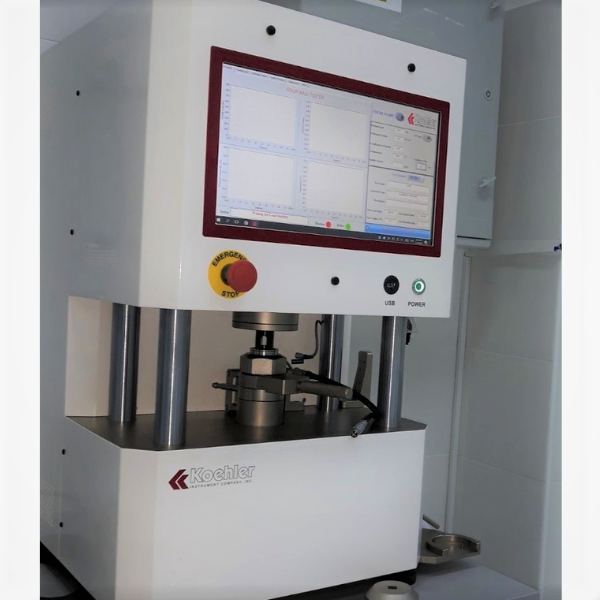

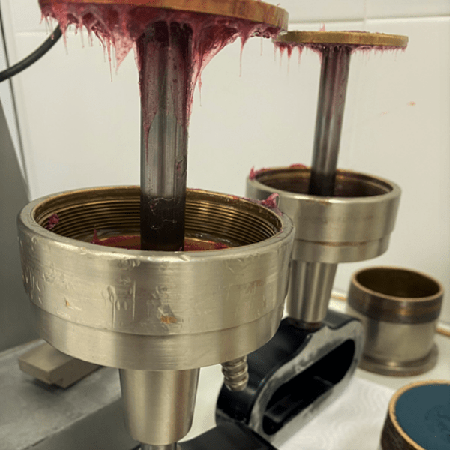

“Valvoline has invested in the latest technology testing equipment,” she says. “We are very proud of our new laboratory that contains more than 100 pieces of equipment and can carry out over 130 different tests. We now have the people, knowledge and expertise to continue to grow.”

Valvoline greases are formulated to perform in even the most demanding environments, ensuring maximum efficiencies and cost savings for heavy industrial applications such as those in the mining, construction, agriculture, steel, forestry and marine industries.

The business is committed to meeting the highest quality standards and the new facility allows its products to be tested for everything from corrosion protection, oxidation stability, and rust prevention to oil separation, roll stability and dropping point.

Diego Brodoni, Vice President and General Manager, Europe, Middle East and Africa, adds, “With this upgrade we deliver a sustainable added value to our partners and customers in the B2B arena and we offer the opportunity to maximize further the performance and the products/applications savings benefit.”

Valvoline is one of the world’s leading lubricant and automotive suppliers, with a portfolio boasting over 500 formulations.

After a year of strong results, Valvoline’s continued investment marks yet another major milestone for the business and furthers its ambitions in this rapidly-growing market.

To find out more about Valvoline’s range of greases, visit https://www.valvoline.com/en-europe/our-products/grease.