Industry 4.0, known as the Fourth Industrial Revolution, emphasizes the importance of digital technologies—integrating internet functionality with countless technologies and impacting all global industries, including the field of lubricants.

The implementation of Industry 4.0 in automation technologies is expected to increase the need for lubricants in advanced machinery and robotics, as machines require lubricant for maintenance, and a boom in robotics and machinery will necessarily expand the lubricant industry twofold.

Industry 4.0 is transforming how products are manufactured, improved and distributed globally, with significant implications in the lubricants market. Key implications include a shift in focus from lubricant knowledge to data systems and digitalization. The implementation of these new technologies—like the Internet of Things (IoT) and Artificial Intelligence (AI)—means that systems can monitor their own effectiveness during the production process.

This article catalogs several recent improvements to the lubricants industry from Industry 4.0, focusing on their implications for the future of lubricant development.

Internet of Things

One of the most revolutionary technologies involved in Industry 4.0 is the implementation of the Internet of Things. IoT is a system of computing devices, machines and objects that connect and exchange data with each other over the internet or other computing devices. The use of IoT devices enables the manufacturing lines, business processes and teams to collaborate regardless of location, time zone or network. This lowers energy emissions, transfers data automatically and dramatically boosts productivity.

IoT is used to create smart grids that assist in reducing and improving energy usage. IoT helps automate resource usage and reduce the power and water consumption of a business. These are all inexpensive systems that can be deployed with simple motion detection devices that detect and measure resource usage to ensure efficient productivity.

In manufacturing, IoT networks are used to create smart factories with the use of sensors and devices to gather data, optimize processes, and identify and offset potential problems. These devices are capable of monitoring parameters like vibration, temperature and oil quality in real-time. Poseidon Systems, a leading New York-based sensor manufacturing company, has created the Trident LH sensor, which monitors the live oil level, quality and water contamination of a given storage unit. The device promotes condition-based maintenance practices, allowing for the detection and resolution of lubricant issues at the earliest possible indication, saving greatly on maintenance and downtime costs.

With real-time data at their fingertips, maintenance personnel can make more informed decisions. This shift from scheduled checks to a monitor-based maintenance approach reduces unnecessary interventions and prioritizes the needs of the machinery. Additionally, connected devices can automatically detect when lubricant levels are low and subsequently reorder lubricant from trusted suppliers. This added feature ensures continuous availability, reducing the chances of halted operations due to a lubricant shortage.

These applications of digital technology, along with the speed and availability of lubricant information, allows shipping entrepreneurs to quickly monitor the condition and quantity of lubricants on shipments and within facilities. IoT devices, namely sensors, allow companies to remotely monitor the condition and levels of lubricants in storage tanks and containers. As transporting lubricants is a precise endeavor, the conditions of the ship must be monitored and brought to proper specifications before the ship sails, necessitating regular oil monitoring systems to ensure that no obstacles interfere with lubricant quality. Thanks to IoT technologies, lubricant monitoring is easier than ever and is reaching new heights in terms of quality.

Artificial Intelligence

As well as the rise of IoT, industrial lubricant manufacturers can significantly benefit from the implementation of Artificial Intelligence (AI) technologies. AI enhances IoT by interpreting the data received from connected devices, enabling intelligent decision-making and optimizing IoT functionality with self-directed input. Sensors collect real-time data on equipment health, wear patterns and environmental conditions. With this information, artificial intelligence can predict maintenance needs and maximize operations with unparalleled accuracy.

The term “big data” refers to the massive datasets produced by businesses and machines every day. Big data can yield valuable insights for businesses, yet these datasets are often too large to process by conventional means. As a result, big data is often analyzed with AI technology, which is able to spot patterns and produce powerful insights normally incalculable by human efforts. Thanks to these technologies, across the lubrication formulation process, production speeds are up to 2,000 times faster than traditional methods.

Furthermore, traditional maintenance schedules often lead to unnecessary downtime or catastrophic failures. AI and other technologies have been proven to identify trends and predict lubricant reapplication needs, reducing downtime by 15%, according to Lisa Williams of Ametek Spectro Scientific. AI algorithms can interpret inspection results, detecting anomalies that may have gone unnoticed.

The collaboration between human inspectors and AI can significantly enhance inspection accuracy and efficiency. AI-powered systems can forecast component wear with remarkable precision, enabling targeted preventive maintenance. According to an article written by Eric Holzer and published by Machinery Lubrication, the predictive ability of AI and machine learning increased the number of critical alerts by 4.5 times on average and increased precision by 3.9 times compared to the conventional alerts.

On a similar note, AI has the ability to drastically lower emissions. A Boston Consulting Group report suggested that AI has the potential to unlock insights that could mitigate 5%-10% of global greenhouse gas (GHG) emissions by 2030. As the industry continues to embrace AI, we can expect exciting advancements that enhance lubrication practices, reduce downtime and maximize equipment performance.

Implications of Industry 4.0

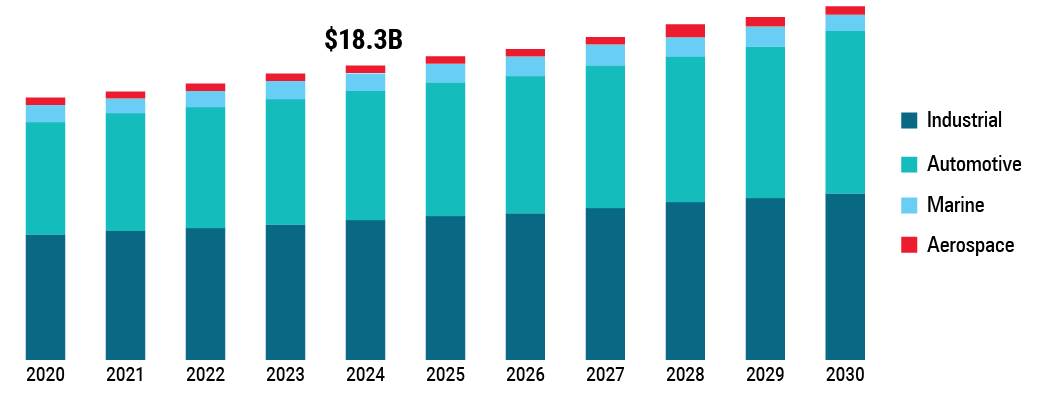

In recent years, the ever-present need for countries to manufacture goods necessitates specialized lubricants. In 2019, the global demand for lubricants totaled nearly 37 million metric tons. According to Statista, the per capita lubricant demand is highest in North America, averaging almost four times the world average of 4.8 kilograms per person. As Figure 1 indicates, the global lubricants market size was estimated to be 139.44 billion USD in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 3.8% from 2024 to 2030 with the continued implementation of Industry 4.0, according to Grandview Research.

Figure 1. U.S. Lubricants Market Size by Application, 2020-2030 (USD Billion)

The projected growth of the U.S. lubricants market from 2020 to 2030, measured in USD billion. Notably, the total market is expected to reach $18.3 billion by 2025. This expansion reflects increasing demand across diverse industries, including industrial, automotive, marine and aerospace.

Source: Grandview Research

The rising demand for solid infrastructure also drives the demand for lubricants, as the heavy construction equipment required for urbanization and large-scale projects require excessive performance lubricants to address the complications introduced by high loads, dust and fluctuating temperatures.

For decades, lubricant manufacturers have been pressured by customers and competing firms to lower costs within the manufacturing process. Industry 4.0’s focus on digitalization allows for just that with its many optimizations. The net result of new technologies is improved maintenance, production efficiencies, waste management and fluid monitoring with less downtime and lowered costs.

In the future we can expect better remote and continuous condition monitoring through the use of smarter diagnostic technology—all helped, supported and enabled through Industry 4.0. By 2035, as digitalization and AI become increasingly adept at detecting faulty or idle machinery, profitability in the sector is expected to improve by up to 38%, a change as significant as the introduction of the assembly line in the early 20th Century.

Conclusion

The shift toward data-driven systems with Industry 4.0 presents a transformative opportunity for the lubricants market. By leveraging data and insights, all parties can better understand the tangible value of high-performance lubricants. Success in this evolving landscape will hinge on the industry’s ability to embrace innovation, develop customized solutions and foster collaboration among stakeholders.

In the future, lubricant management will only digitize further. The rise of machine learning and AI means that data gathered from sensors can be analyzed more effectively to develop further maintenance strategies that are more efficient and effective. Eventually, systems will be fully automated and self-optimizing, proactively circumventing machinery failure before it can occur. These processes are becoming increasingly popular, and operators will soon come in contact with the lubricant less and less. Therefore, they will depend on data systems to predict trends and make decisions.

Bishesh Shah is a freshman studying chemical engineering at Stony Brook University. On campus, he is a member of the American Institute of Chemical Engineers (AIChE) Chapter and a member of the Stony Brook Environmental Club. He aspires to pursue a career in the energy and sustainability industries.

Raj Shah, director at Koehler Instrument Company for 30 years, holds a Chemical Engineering doctorate from Penn State and numerous fellowships and chartered statuses. An Adjunct Professor at SUNY Stony Brook, he has over 650 publications and 30+ years of experience in the energy industry.