In 2000, General Motors was under intense pressure to deliver new six-speed transmission designs with longer lifespans, and along with them a new automatic transmission fluid. In the absence of industry specifications, GM’s well-known Dexron fluids were already synonymous with premium quality ATF, but the latest specification, Dexron-III (H), was unable to meet the new hardware demands. So the automaker made the decision to develop a new spec, enlisting help from chemical additive suppliers and test laboratories. Those involved could not have foreseen the journey to develop the new Dexron-VI specification, which raised the bar for ATF.

As we wish Dexron-VI a very happy 20th birthday in 2025, we look closer at how this landmark performance specification was developed, followed by a licensing program guaranteeing quality and reliability for GM, customers and auto repair shops worldwide.

Scoping the Challenge

The GM Powertrain team was tasked with designing fuel-efficient automatic transmissions, with six speeds instead of four, for 2006 model year vehicles. The new designs necessitated clutch-to-clutch power transfer. At the same time, GM management mandated that its gearboxes’ lifespans should double.

“Engineers consider the fluid as part of any hardware design challenge,” retired Coleman Jones, who was GM’s manager for fuels & lubricants from 2000-2003, explained recently. “All performance requirements must be balanced in a finished formulation.”

Retired Staff Scientist Jim Linden, then chairman of GM’s ATF Committee, remembers meeting engineering teams with GM Powertrain Senior Fluid Engineer Roy Fewkes to ask what they wanted from a fill-for-life fluid.

GM engineers were initially skeptical, possibly because of previous ATF friction challenges with higher torque engines. “GM heavily invested in a Dexron-IV during the 90s,” Linden said. “It reached OEM validation stage before being dropped from consideration.”

“That Dexron-IV candidate was largely developed through bench testing,” Jones admitted. “When it went into a car, the transmission shuddered like crazy.”

The Fuels & Lubricants group also knew that upgrading Dexron-III (H) was not an option. “It lacked the shear stability for long term reliability,” said Linden.

Bringing Expertise Together

By 2001 collaboration on Dexron-VI had begun in earnest. Unlike for industry specifications, additive companies play the primary role in developing fluids for single OEM specifications, an iterative process that works best in parallel with test development.

“We knew that boosting fluid viscosity index with VI improvers wasn’t as effective as getting the right base oil viscometrics,” said Jones. Brent Calcut, now Afton’s OEM director but a co-worker of Jones at the time, recalled, “GM’s oil supplier was promoting higher quality, more saturated base stocks. These Group III oils were capable of supporting a higher performance ATF.”

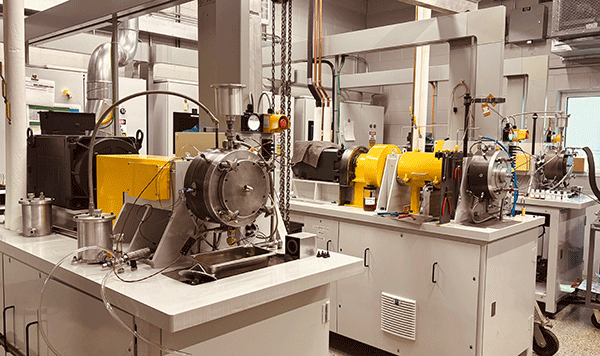

“Previously, we developed most fluid tests at GM Research,” Linden said. “We’d transfer them to independent labs like Southwest Research Institute, approve the test stands, show them how to run the tests and confirm they performed correctly. For Dexron-VI testing we worked more closely with independent labs.”

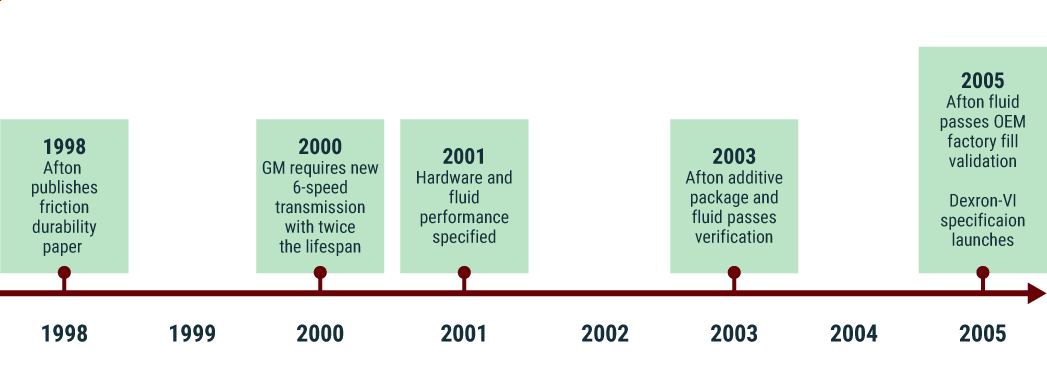

GM asked Afton Chemical to contribute its additive and test expertise. “We’d published a 1998 paper that showed GM we could control transmission shudder by extending the life of our friction modifier,” said Mike Glasgow, of Afton’s OEM Technical Services team. “It was a well-timed and impressive innovation.”

Figure 1. The Pull for a New ATF Spec

Summary of hardware and fluid priorities for Dexron-VI (2001).

| New hardware needs | New ATF requirements |

|---|---|

Effective gear and bearing wear protection that lasts twice as long with known clearances between lubricated parts | Proven shear stability with a low tendency for foaming and aeration to maintain an effective lubricant film under all conditions |

Smooth clutch-to-clutch power transfer at all speeds, with no transmission noise or shudder despite higher torque engines | Precise, durable friction control (i.e. fluid delivers a stable, precisely-shaped friction/speed curve) |

Component surfaces remain clean and corrosion free | Excellent oxidation resistance, with aged fluid retaining its performance and no acidic by-products or deposits |

Extended lifetime for all materials | Lasting materials compatibility |

Injecting Competition

In fact, GM’s Roy Fewkes invited input from more than one additive company. That decision created a highly competitive collaboration, fueling a burning desire to reach the additive solution first and win the Dexron-VI factory fill position.

Two of Afton’s advantages were formulator Sam Tersigni, the gifted data-driven chemist who led Afton’s advances in friction stability, and Tracy McCombs, transmission hardware, performance and testing expert. Tersigni worked long hours. Rumoured to sleep in his office, Afton colleagues jokingly labelled one vending machine “Sam’s Café.” Whenever GM’s Fewkes revealed Afton might be falling behind, Tersigni’s efforts would intensify. Meanwhile McCombs brought his deep understanding of torque converter and clutch engineering and testing.

“Test development involves translating between mechanical and chemical understanding,” explains McCombs. “You can run a fluid to failure and measure how long it takes, but if you stress the fluid in a way that’s not representative of the real world, you risk heading in the wrong direction. A good test is an accelerated way to predict real world performance and discriminate among fluids. Well-interpreted results can show how and why failure occurs, guiding both fluid and test refinement.”

SwRI Executive Director of Fuels and Driveline Lubricants Research Matt Jackson agreed. “Many Dexron-VI challenges related to implementation. Building test equipment is pretty straightforward, but challenges arise when tests don’t behave as expected or don’t immediately discriminate among fluids. Test development is an iterative process. It takes good leadership to avoid becoming bogged down. The GM ATF Committee did a good job of communicating their Dexron-VI needs and were open and responsive to input from our test labs, which definitely helped.”

Translating Needs Into Tests

The first Dexron-VI tests covered fundamental physical and chemical properties, from appearance and elemental analysis to kinematic viscosity, viscosity index and corrosion inhibition. By design, only Group III base oils could pass these criteria.

Shear stability, wear, foaming, material compatibility, and plate and band friction tests came next, many based on Dexron-III (H) with extended run time. Newer tests were also added.

“To double transmission and fluid life, we needed a minimum film thickness greater than for Dexron-III (H) in pumps, bearings and gears,” said Calcut. “GM adopted an innovative lubricant film thickness test developed by a UK university — elastohydrodynamic measurement — into the specification.”

Previous GM hardware developments identified that continuously variable transmission chains can cause considerable fluid aeration. Fewkes and Jackson used this to develop a Dexron-III (H) rig test retained for Dexron-VI. “GM’s Aeration test measured the time it takes for a fluid to go from an unaerated to aerated state, the percentage of air entrained in the fluid and the release time needed to reverse the process,” Jackson said. “Air entrainment was measured using the Coriolis mass flow technique, which to my knowledge had not been used in ATF evaluation before.”

Getting Faster With Friction

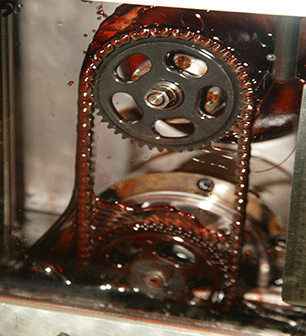

Friction control is the defining feature of any ATF specification. “GM’s band and plate friction tests were extended, the latter doubled to 200 hours,” Afton’s Glasgow recalled. “The friction curve had to be maintained to ensure simulated clutch engagement remained smooth with high torque transfer.”

Afton used its in-house rigs to help develop a low-speed carbon fiber test assessing noise, vibration and harshness and shudder control durability. “To get results for Sam Tersigni faster, we switched our SAE#2 rigs from one full friction test per day to 3 shorter screener tests each day plus a full test with friction map overnight,” McCombs said. “Sam could then eliminate test fluids within two hours instead of waiting 24. He’d hover over data as it printed out, stopping tests dead if things didn’t look right.”

The published low-speed carbon fiber test method was a collaboration between GM, Afton and SwRI, led by Fewkes, Tersigni, McCombs and Jackson.

Pushing the Boundaries

The GM oxidation test, an electric motor-powered full transmission test, was extended from 300 to 450 hours. At 20 days’ run time, it is a high stakes test — although not as high as the Cycling test.

“The Cycling test is like launching a heavy vehicle or towing a trailer from a stop light, going through all the gears in 35 seconds then stopping, thousands of times,” Calcut said. “It emulates real life stresses to challenge the fluid on all fronts.”

Figure 2. Dexron-IV Development Timeline

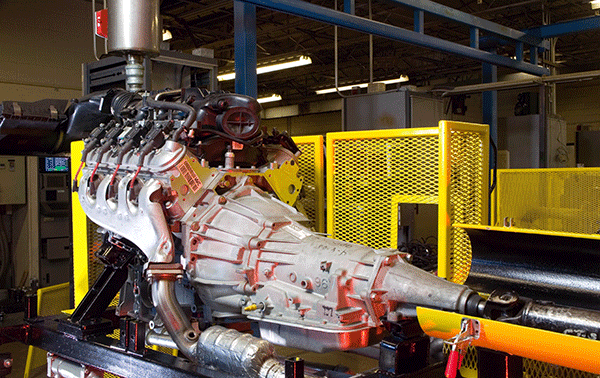

“GM’s 4-speed Cycling test was one of the more challenging Dexron tests,” Jackson said. “It represented a combination of many other rig tests — the 4-speed plate and clutch band friction, wear, aeration, anti-shudder durability and most of the analytical tests. It was the closest thing to a full vehicle test while still isolating transmission performance in a controlled laboratory environment.”

The Dexron-III (H) test used a GM 4L60 4-speed transmission, fired by a Chevrolet 5.7L engine, and specified 32,000 cycles. Dexron-VI testing was set at 42,000 cycles.

Secrets of Success

Throughout test development, GM’s Fewkes – whose drive and determination equalled his technical expertise — kept the transmission engineers motivated with progress and promises, liaised with SwRI and challenged the additive companies with searingly honest updates. At Afton, Tersigni would often tell McCombs, “We must face the brutal facts” — his shorthand for tackling a performance shortfall head-on.

After two years and over 700 blend variants — some still warm when collected for urgent delivery to GM — Afton’s fluid won the race, passing verification in 2003. OEM validation followed, a proprietary process for validating new factory fill fluids.

The Dexron-VI specification was launched on time in 2005 — the start of an era that would see well over 100 formulations licensed by GM.

“Key to success was open and rapid information sharing,” said SwRI’s Jackson. “Open lines of communication between the GM ATF committee and our test labs allowed them to move quickly to implement changes or improvements. We accomplished a lot technically, but the relationships formed were just as important.”

Afton’s Glasgow agreed. “Roy Fewkes could discuss GM’s engineering needs in high level fluid chemistry terms with Sam Tersigni. The commitment and willingness of all the teams involved — especially in our mechanical lab, turning tests around quickly and sharing valuable insights — were the foundation for shared success.”

A Living Legacy

Khaled Zreik, GM fuels and lubricants specialist and a former Dexron-VI Committee chair, was mentored by Fewkes and describes Dexron-VI thus: “A legacy. A standard. A performance evolution to be proud of, which continues to evolve over time.” Dexron-VI became the blueprint for GM’s engine oil specification, dexos, released in 2011.

“Its future depends entirely on future transmission needs,” Zreik said, “but the Dexron-VI specification and licensing program guaranteeing fluid quality remains critical for the global market and service fill. I wouldn’t be surprised if it’s around for another twenty years.”

Afton Chemical thanks those who kindly shared their memories to create this story of Dexron-VI. We are saddened that Roy Fewkes and Sam Tersigni are no longer with us to share theirs; much missed, their legacy lives on.

Adam Banks is Afton’s EMEAI senior marketing manager, ATF. Brent Calcut is the Afton’s Americas OEM relationship director. Mike Glasgow is Afton’s advisor, Americas OEM technical service.