The past century has been marked by a continuous stream of synthetic base oil innovations and the growth in adoption of new synthetic lubricants. These important advances in lubrication technology have provided numerous benefits, such as greater energy efficiency in machinery, enhanced safety to the end-user and consumer through innovations like fire-resistant fluids and food processing lubricants, and bio-lubricants that are kinder to our environment.

The need for innovation in lubrication continues as the manufacturing sector experiences the transformation termed “Industry 4.0,” or the Fourth Industrial Revolution. Advances in robotics, human machine interaction, advanced analytics, additive manufacturing such as 3-D printing, and artificial intelligence are creating demand for new and novel lubricants. Furthermore, there continues to be a significant focus on choosing lubricants that are safer to use and aligned with ever tighter environmental regulations. For example, there is a growing demand for lubricants that are designed from oleochemical versus petrochemical feedstocks.

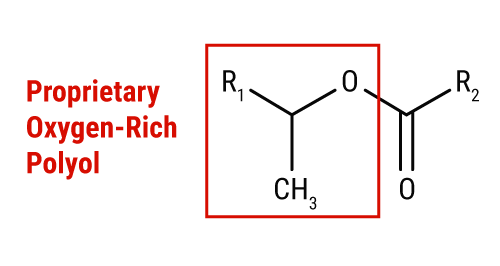

Figure 1. Generic Structure of SPE™

To counter the tribology challenges that the lubricant industry faces today, VBASE Oil Company has dedicated significant research in designing and evaluating a new family of high-performance sustainable base stocks. These oxygen-rich “hybrid” base oils provide many of the environmental functionalities and benefits of classical synthetic esters but also offer many of the functional benefits of polyalkylene glycols.

Chemistry of SPE Base Oils

Secondary Polyol Ester (SPE) base oils have been designed as high-performance sustainable base oils by chemically linking building blocks that are biodegradable to create a family of unique base oils that have a high bio-carbon content and are readily biodegradable. The initial research focused on the commercialization of base oils in the viscosity range ISO 32-100. More recently, research has shown that higher viscosity grades (ISO 100-460) also offer some significant performance benefits, which led VBASE Oil Company to extend the range of SPE products. The commercialization of these higher-viscosity base stocks is expected in the second quarter of 2024.

Novel SPE base oils are referred to as Secondary Polyol Ester base oils because the esterification occurs on secondary hydroxyls of a polyol and links them with fatty acids, preferably from oleochemical feedstocks. Their chemistry comprises a high density of both ester bonds and ether bonds. These highly polar molecules show performance differentiation versus many classical synthetic esters. Their oxygen-rich backbone offers functionality such as in-built detergency, low friction and deposit control.

The unique structure also contributes to a higher viscosity index than many other primary polyol esters of similar viscosities. The inclusion of secondary ester bonds in SPE base oils also slows hydrolysis compared to esters containing primary ester bonds. Furthermore, alkyl branches along the polyol backbone ensure the base oils offer good low-temperature performance (see Table 1).

Table 1. Performance Features of Saturated SPE™ Base Oils (Typical Values)

| Feature | VBASE 32S | VBASE 46S | VBASE 68S | VBASE 100CS | VBASE 220CS | VBASE 460CS |

|---|---|---|---|---|---|---|

Kin. viscosity at 40˚C, mm2/sec | 29.5 | 44.2 | 69.4 | 99.5 | 231 | 445 |

Kin. viscosity at 100˚C, mm2/sec | 6.13 | 8.61 | 12.1 | 16.9 | 35 | 62 |

Viscosity index | 162 | 177 | 173 | 185 | 200 | 213 |

Pour point, ˚C | -51 | -42 | -33 | -18 | -18 | -21 |

Density at 40˚C, g/cm3 | 0.97 | 0.96 | 0.95 | 0.97 | 0.97 | 0.98 |

Aniline point, ˚C, ASTM D611 | <-10 | <-10 | <-10 | <-10 | <-10 | <-10 |

Air release, mins, ASTM D3427 | <1 | 2 | n/d | 3.5 | 8.5 | 16 |

Hydrolytic stability, ASTM D2619 Acid number change, mgKOH/g | 0.28 | 0.13 | 0.2 | 0.46 | n/d | n/d |

Biodegradation, %, OECD 301B | >80 | >80 | >80 | >80 | >80 | >80 |

Bio-carbon, %, ASTM D6866 | 62.5 | 50 | 59 | 57 | 54 | 54 |

EU Ecolabel LuSC List | yes | yes | yes | yes | yes | yes |

NSF HX-1 | yes | yes | yes | Under Review | Under Review | Under Review |

Key Features for Applications

Saturated SPE Base Oils for Industrial Applications. Lubricants used in applications such as mobile hydraulics, gas turbines, compressors and gears are increasingly challenged with managing thermal stresses. Trends in equipment design show more compact systems with tighter filtration, smaller fluid reservoirs and higher pressures. Although petroleum oils are often used, it is common for these to degrade and form deposits that can cause varnish in equipment, resulting in poor fluid flow, blocked filters and ultimately unreliable equipment operation. Moreover, compact systems need to release air rapidly without foaming, and some original equipment manufacturers define low air release times in their specifications.

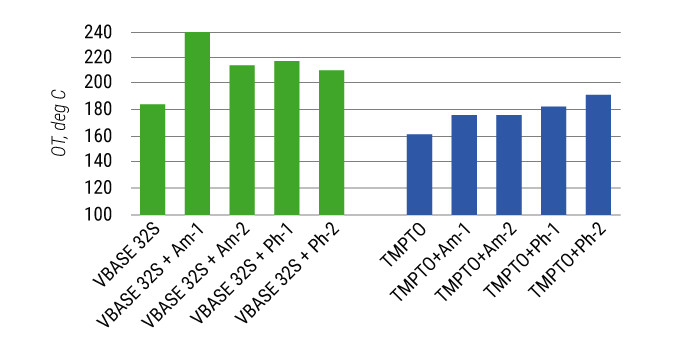

Saturated SPE base oils exhibit excellent oxidation stability and in-built detergency. When formulated with conventional free radical scavenger antioxidants, their stability is further enhanced. Figure 2 illustrates the response of VBASE 32S to four antioxidants (two aminic and two phenolic) at treat levels of 1% in thin-film Differential Scanning Calorimetry (DSC) experiments and compares their performance to trimethylolpropane trioleate (TMPTO).

Figure 2. Oxidation Onset Temperature (OT) Using DSC

Source: VBASE Oil Co.

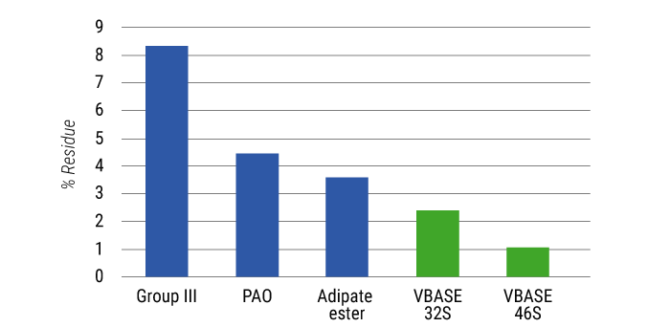

DSC is also a valuable method for evaluating deposit control behavior. Figure 3 illustrates a series of virgin base oils that were exposed to a steady increase in temperature from 20˚C to 400˚C in an air atmosphere. After the test was complete, the residue remaining was measured. The SPE base oils exhibit significantly better deposit control compared to two hydrocarbon base oils and an alternative synthetic ester.

Figure 3. DSC Deposit Control Performance of Base Oils

Source: VBASE Oil Co.

The high polarity of SPE base oils (measured through their low aniline points) can help formulators of synthetic lubricants to mitigate varnish formation under conditions where thermal stresses are high, as thermal breakdown products lead to low deposit formation. Furthermore, if formulators prefer to use a petroleum base oil as their primary base oil, SPE fluids can also be used as a formulation component to provide increased detergency functionality. As the lubricant ages due to thermal stresses, any oxidation byproducts of hydrocarbon oils are solubilized in the polar SPE base oils, helping to maintain equipment cleanliness and minimizing the risk of equipment unreliability. Interestingly, saturated SPE base oils such as VBASE 32S and 46S also offer surprisingly low air release times, which can minimize the risk of cavitation and thermal events in, for example, hydraulic and gas turbine fluids.

New higher-viscosity SPE grades such as VBASE 100CS, 220CS and 460CS offer many of the same features as lower-viscosity grades and are recommended for use as primary base oils for formulating lubricants for heavy-duty equipment, such as bearing, gear and calender lubricants.

Alternatively, SPE fluids are also recommended as a co-base oil in polyalphaolefin (PAO) wind turbine lubricant formulations. Formulations of the latter have used synthetic adipate esters as co-base oils, but these are known to hydrolyze, particularly in off-shore wind turbines where water ingress into the lubricant is more prevalent. SPE technology may offer an alternative option.

SPE Technology for Fire-Resistant Fluids. SPE base oils offer formulators a new technology for developing fire resistant fluids. Polyol esters have been successfully used for many years in hydraulic fluids (HF-DU) and often these are derived from base fluids such as TMPTO. Oxygen-rich SPE base oils (such as VBASE 46U and 68U) offer an alternative. They have inherent low heats of combustion, low volatilities and high fire points (see Table 2). Coupled with the features described above—including their in-built detergency and hydrolytic stability—they offer a unique option for developing fire-resistant fluids that are safe and sustainable.

Table 2. Typical Fire Resistance Performance Parameters

| Feature | ASTM | Petroleum Base Oils* | VBASE 46U | VBASE 68U |

|---|---|---|---|---|

Kin. viscosity at 40˚C, mm2/sec | ASTM D445 | 46 | 53.6 | 67.0 |

Kin. viscosity at 100˚C, mm2/sec | ASTM D445 | 7.0 | 10.7 | 13.0 |

Viscosity index | ASTM D2270 | 110 | 196 | 198 |

Pour point, ˚C | ASTM D97 | -15 | -24 | -39 |

Density at 40˚C, g/cm3 | ASTM D4052 | 0.85 | 0.97 | 0.95 |

Fire point, ˚C | ASTM D92 | 230-250 | 324 | 322 |

Auto-ignition temperature, ˚C | ASTM E659 | 300 | 399 | 408 |

Heat of combustion (MJ/kg) | ASTM D240 | 43-44 | 39.4 | 34.0 |

Noack volatility, % weight loss | ASTM D5800 | 5-9 | 0.8 | 1.0 |

Factory Mutual Approval Standard 6930 assesses fluids for their fire-resistance performance using the Spray Flammability Parameter (SFP). This can be calculated as follows:

SFP (normalized) = 11.02 × 106 × Qch / (d.qcr.mf)

Qch = chemical heat release rate (kW)

qcr = critical heat flux (kW/m2)

d = density of the fluid (kg/m3)

mf = fluid mass flow rate (g/s)

The relationship between critical heat flux and fire point (Tf) is as follows:

qcr = Tf4.α.σ and where

α = surface absorptivity

σ = Stefan Boltzmann constant

The SFP equation shows that a fluid’s fire point, heat of combustion and density are very important parameters in achieving low SFP values. An industrial fluid with an SFP of 5 x 104 or less qualifies as FM Approved. Since SPE base oils have lower heats of combustion, higher densities and higher fire points than petroleum oils—and most other synthetics—it is possible to design fluids that are significantly safer than petroleum oils and meet the FM Approval standard.

Environmentally Acceptable Lubricants. Synthetic and natural esters are a popular choice for formulating bio-lubricants. Many esters are readily biodegradable, and some are derived from oleochemical feedstocks. Each has its own benefits and performance limitations. Natural esters are often used when thermal stresses in equipment are low, because higher operating temperatures can rapidly result in oxidation of the lubricant and a significant increase in its viscosity, while subzero temperatures can induce gelling in extreme cases. Saturated synthetic esters are preferred when thermal stresses are high or when the lubricant is exposed to very low temperatures. Their hydrolytic stability remains a challenge when they are exposed to wet environments. This includes use in equipment operated near or in waterways. Applicable fluids in this application include hydraulic fluids, stern tube lubricants and wind turbine oils.

In laboratory experiments, the hydrolytic stability of SPE base oils is good and offers an alternative option (see Table 1). Moreover, the saturated SPE base oils have good oxidation stability and low-temperature properties coupled with excellent environmental profiles. These have high bio-carbon content and have tested as readily biodegradable. SPE base oils are also listed on the EU Ecolabel LuSC list for formulating environmentally acceptable lubricants and are certified USDA BioPreferred. In addition, lower-viscosity grades are NSF-HX1 accredited, making them an option for formulating food-grade lubricants. The new higher-viscosity complex grades are currently under review by NSF.

To demonstrate performance in equipment, VBASE Oil Company developed a formulated hydro-turbine oil containing an SPE base oil as part of a Department of Energy (DoE) program. The Global Center of Excellence for GE Hydro Solutions in Switzerland successfully verified its performance on a combined thrust guide bearing test rig. The fluid performed well in all operating conditions, including high-load and low-speed operation (mixed friction regime). There was no damage to the bearing pad surface even after a high-load (13Mpa) crash test. The product is now undergoing trials under real service conditions in equipment at the Porjus Hydroelectric Power Station in Sweden. The Porjus Hydroelectric Power Station is Europe’s preeminent hydropower research and development facility operated by Porjus Hydropower Centre Foundation, and is a joint collaboration between Andritz, GE Renewable Energy and Vattenfall.

Summary

The unique chemistry of SPE base oils provides some additional performance functionalities that conventional synthetic esters may not offer, all while providing excellent environmental performance. These oxygen-rich structures—with in-built detergency, good hydrolytic stability and oxidation stability—provide formulators with a new sustainable base oil choice. This new patented platform chemistry—with a vast number of options for designing new base oils or additives—offers a promising solution to solving some of today’s most pressing lubrication and formulation challenges.