A lubricating grease is defined by the National Lubricating Grease Institute as a semi-solid lubricant that is made up of three main components. These components include a base fluid, a thickener as well as performance-enhancing additives. Greases are generally used to lubricate components and machinery in which liquid lubricants are not practical or feasible. These include but are not limited to electric motors, high-speed spindles and wheel bearings.

Best Base Stocks?

According to a 2022 article sponsored by the Society of Tribologists and Lubrication Engineers and penned by Dan Holdmeyer, formerly of Chevron Lubricants, the base stock component of a grease can account for anywhere between 55% and 95% of a finished grease product. Not surprisingly, the base stock provides the majority of the grease’s lubrication properties, so picking the right one is of the utmost importance.

So which types of base stocks are best suited for grease formulation, and might the answer to that question vary based on the finished product’s end use?

“Mineral oils are the most common base fluid used in greases today and are suitable for moderate operating conditions,” Holdmeyer wrote. “Synthetic base fluids, such as polyalphaolefins (PAOs), are preferred for more severe operating conditions like very high or low operating temperatures, or for filled-for-life applications.”

Other synthetic base stocks (i.e., the various types of esters) are also well-suited for more severe operating conditions, but these synthetic fluids often come with a heftier price tag than their mineral oil counterparts.

The base fluid’s viscosity is another important formulation consideration. “The base fluid viscosity needs to match the application,” Holdmeyer said. “Higher-viscosity oils are needed in high-temperature and heavy-load conditions, whereas lower-viscosity oils are needed in high-speed applications.”

Holdmeyer added that the most common base oil viscosity grade used in grease in North America is ISO VG 220.

In the Thickener of It

Making up anywhere from 5% to 30% of a finished grease formulation, the thickener plays a vital role in a grease’s final properties and therefore its applications. It is the component that turns a liquid lubricant (i.e., a base fluid) into a semi-solid lubricant. This, of course, means that a higher concentration of thickener in a grease increases the consistency, which is one of a few vital grease properties.

Grease consistency is generally measured by ASTM D217, Standard Test Methods for Cone Penetration of Lubricating Grease. Consistency is assigned as an NLGI grade (000 to 6). NLGI Grade 000 is the most fluid of the grades, while NLGI Grade 6 is just shy of a solid. Worldwide, NLGI Grade 2 has been the most popular grade for quite some time.

So what types of thickeners are commonly used to formulate greases?

According to NLGI’s annual grease production survey, lithium has held its place as the most popular grease thickener type for some time. In 2022, conventional lithium greases accounted for about 43% of the global market, while lithium complex greases made up approximately 19%.

Calcium thickeners—including calcium sulfonate—were the runner-up and made up about 21% of global production in 2022. It was followed by polyurea, aluminum soap, organophilic clay, other non-soap thickeners, and sodium and other metallic soap thickeners, respectively.

While each thickener’s share of the market is not expected to change significantly any time soon, there are likely to be some subtle shifts in the coming years. Most notably, lithium’s share may begin to decrease, as the lithium supply may be increasingly allocated to the production of batteries for electric vehicles.

Fortunately, this potential shift has been anticipated by grease producers around the world, and considerable research and development efforts are being made to produce high-performing greases that exclude lithium from their formulations.

Apt Additives

Finished greases employ additives to enhance the lubricating properties of the base oil-thickener combination and to ensure that the finished grease is able to adequately perform in its respective application.

According to Sea-Land Chemical Company, some of the most common classifications of additives used in lubricating greases include the following:

- Solid Lubricants: These additives include molybdenum disulfide, graphite and polytetrafluoroethylene (PTFE), which can improve load-carrying capacity as well as protect against wear.

- Oxidation Inhibitors: These additives help to prevent grease break-down caused by metal wear particles and heat.

- Extreme Pressure Additives: These additives protect metal surfaces when they are subjected to heavy loads, extreme temperatures and high levels of pressure.

- Lubricity Additives: These additives enhance a grease’s ability to reduce friction and minimize wear.

- Antioxidants: These additives maintain grease integrity by scavenging radicals that are formed during oxidation.

- Corrosion and Rust Inhibitors: These additives provide protection against acidic products and rust formation.

Global Grease Production

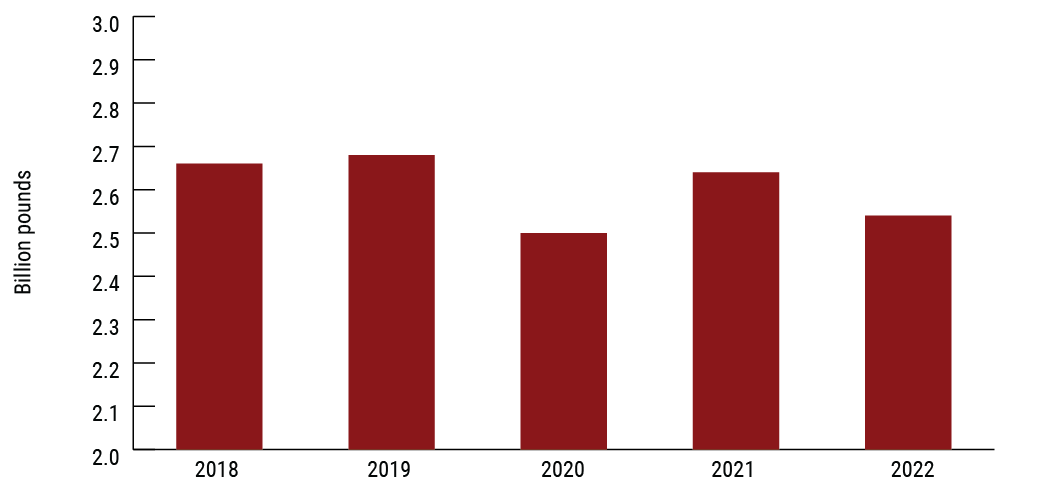

With the exception of a nearly 7% pandemic-induced drop-off in 2020, global grease demand has remained relatively steady for the past five years. However, ringing in at just over 2.5 billion pounds, global grease production in 2022 did drop off by about 4% from 2021 volumes.

According to NLGI’s annual grease production survey, the top three grease-producing regions in 2022 were Asia, Europe and North America, respectively.

Figure 1. Global Grease Production Over Time

At about 1.5 billion pounds, grease production in Asian countries greatly outpaced production in other regions. In fact, at a little over 474 million pounds, grease production in Europe in 2022 was just 32% of that in Asia. Likewise, North American grease production—which clocked in at just under 389 million pounds—was just 26% of Asia’s total volume.

Sydney Moore is managing editor of Lubes’n’Greases magazine. Contact her at Sydney@LubesnGreases.com