Slide your finger along the surface of an object made of polytetrafluoroethylene (PTFE) and you will immediately understand the value of this plastic. The slipperiness is similar to that of a protective wax coating on an apple or a thin film on a wet or icy roadway. PTFE is “self-lubricating.”

PTFE is a fluoropolymer synthesized from tetrafluroethylene. It is valued for its very low coefficient of friction, chemical inertness, dielectric properties, resistance to water and oils, and stability, strength and toughness over a wide temperature range. Applications include thin film lubricants, powdered additives for lubricants and greases, gaskets, seals, bearings, gears, valves, insulation for wiring, coatings, medical devices, and uses in the aerospace and semiconductor industries.

However, PTFE may be regulated and even banned, similar to such hazardous substances as lead, mercury, arsenic, chromium (VI), radioactive isotopes, asbestos, formaldehyde, cyanides and benzene.

EPA Regulation of Fluorosurfactants

Since the 1990s, the U.S. EPA has taken a carefully considered approach to the regulation of specific per- and poly-fluoroalkyl substances (PFAS) known to have adverse effects on human health and the environment. Certain PFAS are regulated because they are persistent (degrade very slowly in the environment), bioaccumulative (gradually accumulate in organisms) and ubiquitous (present in thousands of samples of drinking water, food, dust, formulated products and packaging materials).

According to its Strategic Roadmap: Commitments to Action 2021-2024, the EPA is pursuing “a comprehensive approach to proactively prevent PFAS from entering air, land and water at levels that can adversely impact human health and the environment.”

Earlier this year, the EPA proposed a National Primary Drinking Water Regulation (NPDWR) and health-based Maximum Containment Levels (MCL) of six PFAS that are fluorosurfactants. An MCL is the maximum allowed level of a contaminant or group of contaminants in water that is delivered to a public water system (PWS). A fluorosurfactant is a molecule that contains an oil-soluble fluorocarbon “tail” and a water-soluble “head” and has unique properties in fluids, on surfaces and at interfaces.

Individual states and municipalities are responsible for complying with EPA regulations on monitoring, testing and reporting to ensure that PWS meet national limits on regulated PFAS, such as fluorosurfactants PFOA and PFOS. States and major retailers are restricting or eliminating the use of specific PFAS in certain products.

The EPA and state agencies concluded that the metal finishing industry is a significant source of PFOS emissions to wastewater treatment plants. There are 189 PFAS among 770 chemicals in the Toxic Release Inventory (TRI). U.S. facilities in certain industrial sectors must submit annual reports on the amount of each chemical listed in the TRI that they release to the environment, treat or recycle.

Last year, the EPA submitted a draft of an Information Collection Request for the Metal Finishing and Electroplating Industry for review by the Office of Budget Management. If approved, it will be sent to facilities to obtain information about their current and historic activities and use of PFAS.

William Lipps of Shimadzu Scientific Instruments and a member of ASTM Committee D19 on Water, said: “The EPA regulations are, in my opinion, going to have a ripple effect into industry, forcing manufacturers of many products … to verify by process knowledge or by testing that there are no organic fluorine compounds in their products.”

Even when PFAS are not in use, treatment baths and systems can be contaminated by persistent PFAS from historic operations and residues on parts provided by customers, which could implicate suppliers of cleaners, metalworking fluids and other products.

The use of “recommended” instead of “final” or “approved” test methodology for analysis of parts per trillion levels of PFAS is a concern. “As far as I know, there are no standardized methods for quantifying PFAS in formulated products, such as metalworking fluids, lubes and greases,” Lipps said. “Hopefully, ASTM F15 and other committees will work on this. We do know that the D19 Method D8421 does work well for metal washing and plating solutions.”

EU Regulation of Fluorosurfactants

In 1995, the UN called for global action to regulate persistent organic pollutants (POP), i.e., “chemical substances that persist in the environment, bio-accumulate through the food web and pose a risk of causing adverse effects to human health and the environment.” The result was the Stockholm Convention, an international environmental treaty intended to eliminate or restrict the production and use of specific POPs.

The Stockholm Convention is in effect in 185 nations and the EU (but not the U.S., Israel or Malaysia). The list of regulated substances is dynamic and includes fluorosurfactants.

In 2006, the European Chemicals Agency (ECHA) was established as an independent NGO for the implementation of REACH in the EU. One of its goals is to ensure the credibility of legislation, decision making and underlying scientific bases regarding chemicals.

The REACH Candidate List of substances of Very High Concern (SVHC) contains specific fluorosurfactants, including some of those listed in the EPA’s NPDWR.

Universal Regulation of PFAS in the EU

In January 2023, the national competent authorities of Denmark, Germany, the Netherlands, Norway and Sweden submitted a proposal to the ECHA to regulate the production and use of PFAS as defined by the OECD. National competent authorities are organizations that have been legally delegated to perform a designated function, e.g., monitor compliance with national statutes and regulations.

The OECD defines PFAS as “fluorinated substances that contain at least one fully fluorinated methyl or methylene carbon atom”—in effect, any chemical with at least a perfluorinated methyl group or a perfluorinated methylene group.

The proposed restriction is “universal,” i.e., intended to reduce the emission of almost all PFAS into the environment and make products and processes safer for people.

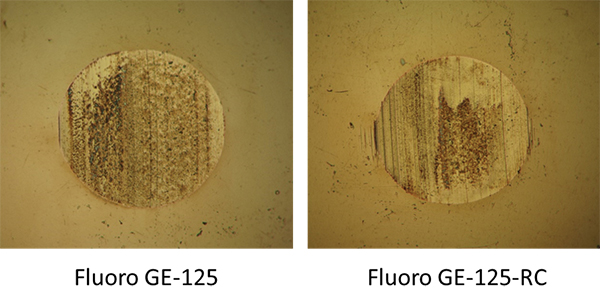

Figure 1. Wear scar diameters (mm) from 4-ball wear tests of PAO thickened with 50% PTFE: typical (brown) and regulatory compliant (green) versions of three grades of PTFE.

Source: Image courtesy of Shamrock Technologies, Inc.

According to the ECHA (http://echa.europa.eu/): “All PFAS in the scope of the proposal are very persistent. If their releases are not minimized, people, plants and animals will be increasingly exposed, and without a restriction, such levels will be reached that have negative effects on people’s health and the environment. The authorities estimate that around 4.4 million tons of PFAS would end up in the environment over the next thirty years unless action is taken.”

The Annex XV Restriction Report, Proposal for a Restriction on PFAS contains details about production and use of PFAS and proposed restriction options (RO) under REACH for PFAS in 14 use sectors.

The rationale includes the very long (“intergenerational”) persistence of PFAS; increasing global volumes; variety of emissions sources; mobility through air, water and soil; increasing levels in the environment; technical difficulty and expense of remediation; and adverse effects on human health and the environment.

In addition, “despite the phase-out of PFOS and PFOA, they are still detected at high levels worldwide, illustrating that contamination of PFASs is poorly reversible and underpins the need to restrict also other PFASs to avoid similar problems in the future,” according to Annex XV. “Furthermore, the presence of precursors, such as side-chain fluorinated polymers, will remain a long-lasting source of PFAAs in the environment even after a phase-out of production.”

Figure 2. Fluorosurfactants and MCL in Drinking Water Proposed in the EPA’s NPDWR

| Substance | MCL | |

|---|---|---|

| PFOA | perfluorooctanoic acid | 4.0 ppt |

| PFOS | perfluorooctyl sulfonate | 4.0 ppt |

| PFBS | perfluorobutane sulfonic acid | TBD |

| PFNA | perfluorononanoic acid | TBD |

| PFHxS | perfluorohexanoic acid | TBD |

| HYPO-DA (GenX) | hexafluoropropylene oxide dimer acid and its ammonium salt | TBD |

In March, ECHA’s Risk Assessment (RAC) and Socio-Economic Analysis (SEAC) Committees started a six-month project to determine whether the Proposal meets the legal requirements of REACH and evaluate its likely effects on PFAS emissions, socio-economic impact and feasibility.

More than 5,600 comments (200-plus from the U.S.) on the Proposal were submitted for consideration by the RAC, SEAC and five countries that prepared the initial Proposal.

In early November, the RAC and SEAC were “evaluating the proposed restriction and considering the relevant information,” according to the ECHA. “ECHA will deliver the final opinions to the European Commission in the shortest possible timeframe … Once the committees adopt their opinions, they will be communicated to the public. The Commission, together with the EU Member States, will decide on the restriction.”

If the proposed regulation enters into force, restriction option RO1 would allow a transition period of 18 months followed by a ban. Option RO2 would allow a five- or 12-year “derogation” period for development of replacements in specific applications, followed by an 18-month transition period and ban.

The ban would completely eliminate the manufacture, import and use of PFAS in the EU.

In addition, the ban would restrict the sale of PFAS as a constituent of another substance, a mixture or an article at a concentration of or above the following levels:

- 25 ppb for any PFAS as measured with targeted PFAS analysis (polymeric PFAS excluded).

- 250 ppb for the sum of PFAS measured as the sum of targeted PFAS analysis, optionally with prior degradation of precursors (polymeric PFASs excluded).

- 50 ppm for PFAS (polymeric PFASs included).

If total fluorine exceeds 50 mg F/kg, then the manufacturer, importer or downstream user could be required to provide proof for the measured F content as either PFAS or non-PFAS upon request.

Lipps noted that PTFE is not detected by the methods proposed to test for other PFAS, although it could be detected by some methods that measure total F on surfaces. The Combustion Ion Chromatography method developed for screening water samples for absorbable organic fluorine does not extract and combust samples under favorable conditions to quantitatively measure polymeric PFAS, such as PTFE.

“The best approach would be to develop analytical methods for specific compounds that can be linked to realistic toxicity data and have a demonstrated risk of environmental contamination or human (or animal) ingestion,” Lipps said. “Just because there may be PFAS compounds in a product does not make them hazardous.”

What About PTFE?

In Annex XV, the impacts of the manufacture and use of PFAS were analyzed separately for perfluorinated alkyl acids (PFAA), fluorinated gases and polymeric PFAS.

Estimated annual tonnages of polymeric PFAS were 26%-42% of the manufactured total and 24%-40% of use in major sectors. No data were presented for specific polymeric PFAS, such as PTFE.

The lubricants sector was estimated at 0.51%-0.76% of the total and almost entirely polymeric PFAS. Regarding lubricants containing PFAS, the Proposal noted a lack of technically and economically feasible alternatives only for applications under harsh conditions or for safe functioning of equipment. “Functionality loss, e.g., related to performance level and lifetime, is likely to affect an unknown number of industries and end users. Product reformulation costs are estimated to range between tens of thousands and several million euros, but reformulation is unlikely to be possible within the given timeframe,” according to the Proposal.

Figure 3. Fluorosurfactants and Status of Restriction by the Stockholm Convention

| Substance | Status |

|---|---|

| PFHxS, its salts and PFHxS-related compounds | Production and usage eliminated in 2020. |

| PFOA, its salts and PFOA-related compounds | Production eliminated, with the exception of fire-fighting foams (covered by a different regulation). Usage eliminated except for specific exemptions in 2019. |

| PFOS, its salts and perfluorooctane sulfonyl fluoride | Production restricted to specific uses, including hard metal plating, insect baits for control of leaf-cutting ants and fire-fighting foams in 2009. |

| Long-chain perfluorinated carboxylic acids (C9-C21 PFCAs), their salts and precursors | Under consideration for inclusion in the Stockholm Convention and consequent elimination of global production and use. |

“PTFEs are used in greases and lubricants for automotive, industrial, aviation and aerospace, semiconductor, medical, marine and specialty valves applications, among others. The main benefits derived from PTFEs are anti-wear protection, friction reduction, heat resistance and thickening properties,” said Ronald Levitt of Shamrock Technologies, Inc.

The American Chemicals Council (ACC) contends that most fluoropolymers “meet internationally recognized criteria for being considered polymers of low concern (PLC), a designation for compounds that are expected to have insignificant environmental and human health impacts.” Toxicity data, human clinical data, and physical, chemical, thermal and biological data showed that PTFE is neither bioavailable nor bioaccumulative. Eighteen fluoropolymers, including PTFE, meet all 13 criteria for PLCs, are “distinctly different” from other PFAS and should be considered separately for regulatory purposes.

However, PTFE may contain other PFAS, such as fluorosurfactants, from their synthesis or treatment to manufacture micropowders.

Since 2020, Shamrock has proactively quantified PFOA in samples of PTFE micropowders. Its regulatory-compliant PTFE micropowders contain less than 25 ppb PFOA, and their performance is comparable to that of its other products.

Mary Moon, Ph.D., has experience formulating, testing and manufacturing lubricating oils and greases and polymers. She has served as Chair of the Philadelphia Section of STLE and Technical Editor of The NLGI Spokesman and received the Clarence E. Earle Memorial Award (2018) and the Golden Grease Gun Award (2022) from NLGI. She is currently working as a professional writer and editor. Contact her at mmmoon@ix.netcom.com