Researchers at Germany’s Fraunhofer Institute for Mechanics of Materials say they have developed a virtual lab to predict effects of electrical fields on lubricant stability in components such as mechanical bearings and gearboxes used in electric vehicles and wind energy turbines, enhancing maintenance and supporting customized formulations for new products.

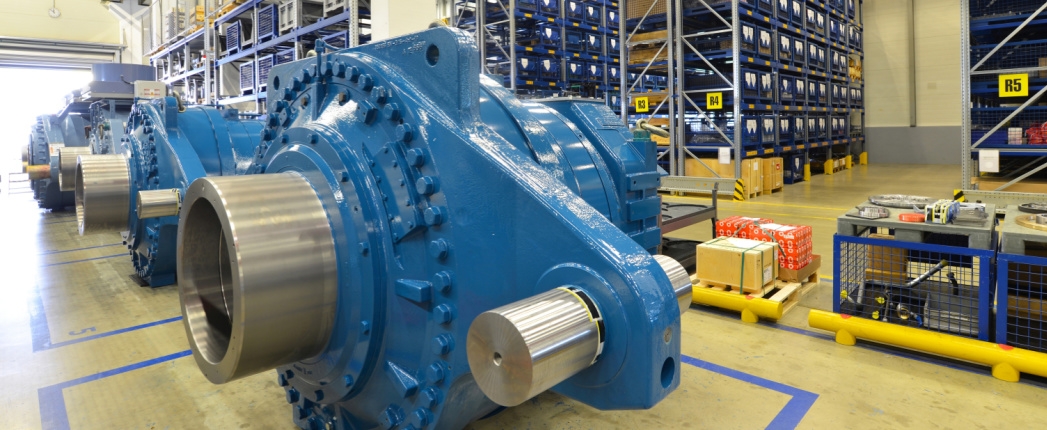

The institute outlined its findings in a Sept. 1 press release, stating that electrical fields impact the efficacy of lubricants in tribological systems such as bearings, thereby compromising the components’ lifespan. It added that electrical charges are especially important in electric vehicles and windfarms. For example, such applications use large volumes of lubricants on rotor bearings to reduce friction and wear, but electrical fields can damage additives in the lubricants, the institute stated.

“The short- or long-term separation of these additives may lead to electrical breakdown and component damage,” the press release said. “This problem is increasingly taking center stage against the backdrop of the energy institution.”

According to the institute, up to this point, offshore wind farms only monitored lubricants during regular maintenance, which can be especially difficult to perform in winter because of weather conditions. The Lube Life joint research project, in which the institute is a partner, developed a sensor that includes infrared, moisture, acoustic and friction sensors, along with evaluation electronics, to monitor the lubricants in real time. The sensor data, along with predictive online algorithms and simulated analysis data, are combined to create an overall assessment of the lubricant.

The institute said its research can calculate several other lubricant parameters, including viscosity, thermal conductivity and chemical reactivity with surfaces. The information can be used to determine the effect of adding certain amounts of a particular additive. “By interacting with the virtual lubricant lab, a variety of measures can be taken, ranging from simple notification and triggering of a maintenance order, to the automated additional dosing of additives,” the researchers stated.

Project coordinator Qass developed software to collect sensor signals that are then analyzed in the software’s central part, known as the virtual lubricant lab. The virtual lab enables assessment of existing lubricants based on their electrotribological suitability, the institute said. It also allows for qualification of lubricant additives and a preliminary assessment when designing a lubricant. Stabilizing the lubricant by adding suitable additives to extend the use phase is a key objective.

“The virtual lubricant lab offers many different types of support,” Michael Moseler, head of the Tribology business unit at Fraunhofer IWM in Freiburg, said in the press release. “It helps to change the additive composition in a lubricant in cases where, for example, an additive is no longer available, or its use is legally prohibited for environmental reasons. The same applies if a lubricant no longer works properly because an additive has formed droplets and the lubricant’s dielectrical properties have changed, meaning that adjustments are required.

“To date, our project partner ASC Goerlach has illustrated this using a heuristic computational model. We were able to use molecular dynamics to show that a reduction in energy of solvation due to strong electrical fields can cause droplets to form. These droplets can significantly reduce a lubricant’s dielectric strength.”

The institute expressed enthusiasm about future areas of application for the virtual lab, saying that in addition to monitoring wind farms, a real-time, decentralized analysis and forecasting system for lubricants could help improve operations at factories and power plants.

Funded by the German federal Ministry of Education and Research the Lube Life project’s partners include ASC Goerlach, Fraunhofer IWM, Fuchs Schmierstoffe GmbH, Hydac Electronic GmbH, Kompass GmbH, Qass GmbH and Schaeffler AG.