The fire-resistant synthetic turbine oils consumed in Russia are mostly imported products formulated with trixylenyl phosphate, an anti-wear additive used in high-temperature applications. Acquiring them has become more difficult since the start of the war in Ukraine, so a local independent additive maker is developing cheaper analogues that it claims are safer.

Russia consumes around 500 metric tons of these oils annually, and the market is expected to grow to 800 t/y by 2030, according to a company official with Qualitet, the chemical additive maker, which is located in Moscow.

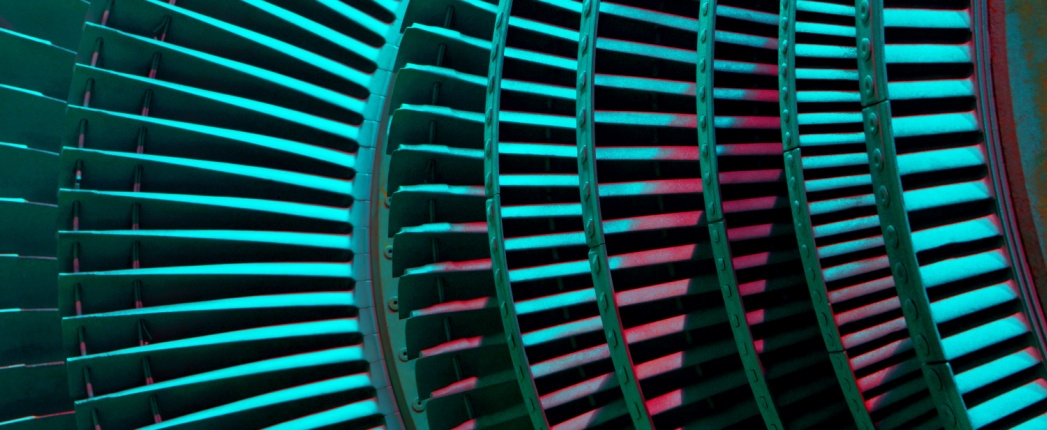

Fire-resistant oils are difficult to ignite and inherently self-extinguishing – that’s why they are used in applications such as lubricating high-power steam turbines in thermal or nuclear power generation stations, where high temperatures are prevalent and can ignite mineral base fluids. Besides high oxidative and thermal stability, these oils have good hydrolytic stability.

In prevalent formulations, these products also have high toxicity and are harmful to humans.

“Prior to 2022, Lanxess and ICL Industrial Products were the main foreign suppliers of fire-resistant oils to Russia,” Alexander Medzibovskiy, general director of Qualitet, told the RPI’s Industrial Oils and Metalworking Fluids Conference in Moscow May 23. He added that the two companies have halted shipments to Russia. Medzibovskiy did not provide a reason, but numerous foreign businesses withdrew from Russia after its invasion of Ukraine.

“These oils are still available, but re-exported to Russia through third countries, so their prices grew at least by 40%,” Medzibovskiy added. The fluid from Germany-based Lanxess was its Reolube 46 RS fire-resistant oil, while the one supplied by Israel-based ICL was its Fyrquel-L, a specialty fluid made with triaryl phosphate ester base stocks.

Reolube 46 RS is based on an Omti formulation developed by Soviet Union chemists and sold to Western companies in the 1990s. Omti is the acronym for fire-resistant oil of the All-Union Thermal Engineering Institute, a scientific institution where the fluid was developed. In 2019, the Omti formulation was revived by Rosneft specialists who promised to soon begin producing a cancerogenic-free version of the product at the company’s lubricant and additives plant in Novokuybyshevsk. It is unclear it that production has begun.

Medzibovskiy claimed that although Qualitet possesses technology to produce analogues of these products, the manufacturing process is very challenging.

“There is a shortage of supply of the raw material xylenol fraction,” he said. “This is toxicologically a very active substance that can harm the human reproductive system. Also, the property of the product depends on the isomeric composition of the xylenol fraction.”

Qualitet developed an alternative formulation based on tert-butylated triphenyl phosphate. Medzibovskiy discussed pros and cons of manufacturing the product. Pros include that it is made with available raw materials, that it has high oxidative stability, a lack of specific odor, that it is toxicologically safe for the humans and high biodegradability. Cons include relatively low hydrolytic stability and relatively slow deaeration.

Qualitet has also collected a large amount of used fire-resistant fluids at its Moscow facilities, he said. According to the company’s website, its factory has capacity to produce 2,500 metric tons per year of sulfonate additives; 5,000 t/y of phosphorothioate and phenate additives, succinimide, polymer viscosity modifiers and depressants; and over 10,000 t/y of additive packages and motor oils.