Spain’s Ministry of Science and Innovation and the European Union, through its Next Generation fund, are financing a project to develop advanced services for intelligent management of lubricants through the use of artificial intelligence and technologies that communicate with machine tools via the Internet.

The project, known as SmarTaladrine, brings together several partner companies. According to a press release, it is led by Hypatia GNC Accesorios, part of the Nicolas Correa Group in Spain. participating on the lubricants side is Enriel, a company specializing in distribution, monitoring and condition control of lubricants.

Project partners on the machining side include Mecanizados Especiales and the Miranda de Ebro Technology Center Foundation, specialists in Internet of Things technologies and communication with machine tools. Providing further technological expertise to the project is the Applied Computation Intelligence Research Group of the University of Burgos, experts in the development of problem solving tools that use artificial intelligence.

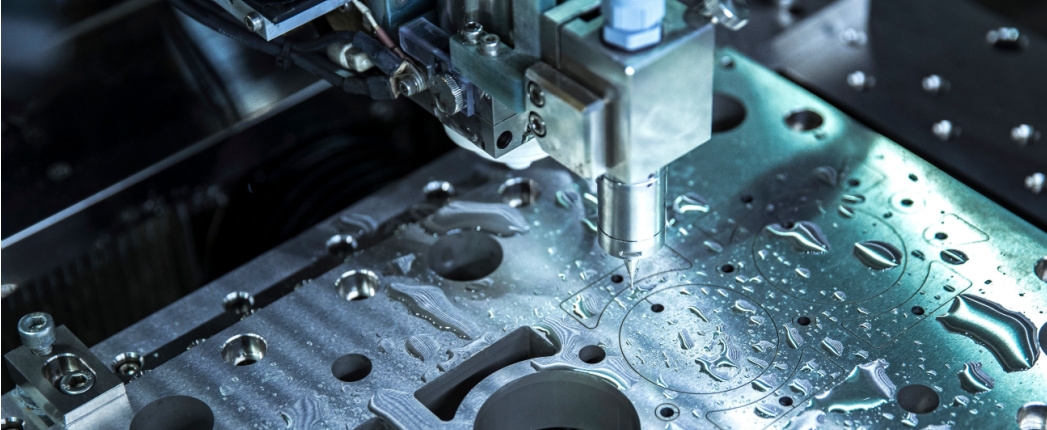

“The general objective of the SmarTaladrine project is to design and develop an innovative solution that models the behavior of the coolants and their relations with the conditions of the environment and machine variables, allowing them to be acted upon with guarantees,” the press release states.

Researchers believe systems that adapt a lubricant’s application and performance in response to variations in its environment can be developed from a combination of machine learning and big data, the collection and integration of heterogeneous and complex data about fluid data and machine conditionsfrom different sources.

The project partners plan to develop two solutions in order to accommodate different circumstances of potential users – one that will be embedded in the machine for operators buying new equipment, the other a modular accessory that can be connected to machines already in operation.

The partners believe the advance they are pursuing for monitoring smart machines and managing the fluids and lubricants they use will enable a revolution for innovation and cost and time savings.

“Operations monitoring in smart machine production will bring numerous advantages over conventional production and manufacturing, resulting in improvements in flexibility, productivity and sustainability,” the press release claims.

The project’s goal is a smart solution that adapts to the needs and expectations of machinists to efficiently and sustainability manage an essential product in their work, such as a coolant. “Moreover, this preventive maintenance solution will allow further progress in the design and development of high-tech machine tools that contribute to the ecological and digital transition of the industrial sector and in the implementation of advanced services for the intelligent management of lubricants,” the press release stated.