Lubricants and other nonfood compounds play an important role in the safe operation of food processing and production plants—but how are they actually used in a food processing facility? And how do they help protect the food supply chain? Claire Goring, supply chain and technical consulting manager at NSF International, a global public health and safety organization, explains the activities in a food processing facility, points of potential contamination and the legislation and globally accepted ways of mitigating risks in food production.

Technical and operations managers at food processing plants work in a busy, high-pressure environment, which I learned over 15 years as a manager responsible for safety and quality issues in food production. For example, a factory producing pastries may have meat, vegetarian and vegan items in production that may also have “free from” requirements, such as gluten-free or lactose-free.

On top of this, plants may be producing multiple brands, such as supermarket store brands and independently branded products, which have different recipes and different production run lengths for each product. There are distinct lines of production equipment for some items and other lines that need to be changed from one product to another. In the latter case, special precautions and cleaning procedures are in place to prevent cross-contamination, which could endanger consumers with allergies.

Manufacturers are committed to making quality products that are safe for the consumer to eat. To achieve this, they must manage all safety aspects within the specified production schedules for a multiplicity of products, often within tight deadlines. When production demand is high, there is more likelihood of human error or equipment failure, both of which could lead to serious and life-endangering contamination of products, including by lubricants and cleaners.

The Five Main Safety Challenges

- Machinery with Moving Parts – Food processing is largely a mechanical, semi-automated activity. Processing prior to assembly can include a number of different operations, each with a varying level of mechanical intervention. This includes cooking and chopping, amongst others. In most cases, there is limited risk of contamination directly from the lubricants used; however, when using lubricants, it is key to strike the right balance between ensuring the equipment operates correctly and minimizing the risk of contamination.

For example, in a dicing and slicing operation, if the fitting of the blade is poor or is not moving correctly, the blade can get damaged and small pieces of metal could transfer into products. Although the lubricant itself may not present a direct contamination risk, incorrect application may give rise to other types of contamination due to poor functioning equipment.

In hot and cold mix operations, there is a risk that if lubricants are incorrectly applied to the rotary functions of the mixing vessels, the mix could be directly contaminated by lubricants. - Accidental Introduction of Allergens – What is the allergen statement of the lubricants being supplied? Many factories now supply “free from” or vegan products and must ensure that any lubricants and chemicals used also meet these requirements. Any supplier should be able to provide such statements and guarantees.

Some “free from” factories may also send the lubricants for testing if the company suspects there may be an issue with a particular allergen. I have even been asked for allergen certificates from pest control contractors to show that there is no gluten in the baits. - Chemical Residue – All cleaning chemicals must be approved for use in the country of operation and, in most cases, also be on a more restrictive retail customer-approved chemical list. In the case of clean-in-place operations for mixing vessels, tanks and silos, pH and conductivity readings of the rinse water at the end of the cleaning cycle ensure the cleaner has been completely removed.

For manual cleaning operations, there are detailed instructions for use of detergents and sanitizers suitable for food factories, along with key post-cleaning inspection points. The inspection may also involve basic lubrication and greasing following cleaning to ensure the machinery can function as it should. - Frequent Maintenance – One of the biggest challenges with machinery often stems from the age of the equipment, which can impact the maintenance required to keep it running. More frequent maintenance activity gives rise to increased risk of the product being contaminated with any lubricants used as part of this process.

- Line Start-ups and Changes – The highest risk of contamination occurs during line changes and start-ups, when the line must be cleaned and serviced before a new production run. Lubricants and greases are used here—and all of them must be food grade if there is the slightest chance of incidental contact with the food. Non-food-grade lubricants can only be used on internal parts of machinery where food contact is physically impossible. Even then, most manufacturers would prefer to use food-grade products if suitable ones are available.

Managing Hazards

Good training for engineers and operators is key. Correctly maintained, well set up equipment, operated and maintained by trained staff who use the correct tools and understand the equipment and the lubricant products, contributes greatly to the smooth and safe running of the factory.

The production process is strictly governed by three layers: national food safety legislation, voluntary food safety standards set by national and international organizations such as the British Retail Consortium and the Global Food Safety Initiative, and private standards set by the customers—whose requirements often far exceed those set by legislation and trade norms.

Regular food safety incidents, scandals and even deaths continue to drive food safety standards and voluntary schemes to become ever more comprehensive. For food manufacturers, compliance with the highest standards is a necessity specified by their customers.

When choosing lubricants, cleaning chemicals and food contact materials, the manufacturer must understand the products, their composition and the potential for contamination and harm. The NSF White Book is one tool that managers can use to ensure a lubricant is approved for use in a food-handling environment. NSF reviews, evaluates and registers specific products for use in the food manufacturing process and maintains the public reference online.

A Hazard Analysis and Critical Control Point system is the most recognized method of managing food safety hazards in a production environment. It involves identifying where there are risks to food safety and the critical control points on which a business needs to focus to ensure those risks are removed or reduced. The business must document its procedures to prevent problems and its plan to rectify any that arise.

The main types of food safety hazards are microbiological, involving harmful bacteria; chemical, involving chemical contamination; and physical, involving non-food objects getting into the food.

Chemical hazards include cleaning chemicals and lubricants that unintentionally come into contact with food. Good practices can minimize the danger of minor lubricant leaks but not eliminate it completely. Any manufacturer that is not using food-grade lubricants is taking an unnecessary risk. Guidance provided by the United States Food and Drug Administration dictates that zero non-food-grade lubricant can contact food. If it does, then the batch must be discarded.

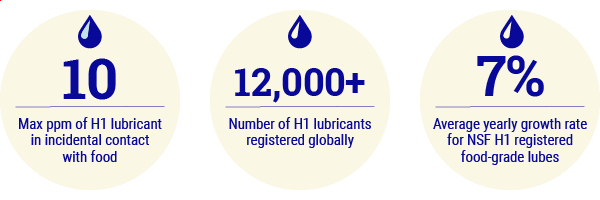

However, it is a common misconception that if food-grade lubricants are used, contamination is not important. On the contrary, regulations set in Part 178 of the FDA’s Code of Federal Regulations Title 21 establishes the maximum permitted amount of lubricant in incidental contact at 10 parts per million.

According to the British Retail Consortium, “Food-grade lubricants are formulated in such a way that if small quantities of technically unavoidable residues enter the processed product, they have no adverse effect and are deemed innocuous in terms of health, taste and odor. However, it should be noted that food-grade lubricants are not intended for human consumption or for contact with skin or mucous membranes.”

To help ensure compliance with these rules, the minimum amount of H1 (food-grade) lubricant that is technically feasible should be used. Using only registered H1 lubricants is a practical solution to addressing HACCP critical control points.

Over and above HACCP legislation, the various Global Food Safety Initiative standards are almost universally demanded by larger retailers. They include BRC, International Featured Standard, ISO 22000, Food Safety Management and Safe Quality Food. Certifying to one or more of these standards is a baseline for food manufacturers seeking to sell their products in global markets.

A manufacturer’s choice of lubricant products can lead to success or failure in obtaining certification to a GFSI standard. This is a key reason why the use of registered products is rising rapidly.

“With a yearly growth rate of 5%-10% over the last few years, NSF has now listed over 12,000 H1 lubricants from around the world,” said Srdjan Stankov, NSF’s EMEA coordinator for the Nonfood Compounds program. “A substantial part of this growth can be attributed to Europe, where many major lubricant manufacturers are based. In fact, 45% of H1 registered lubricants are from the EU.”

It is not enough, however, to simply know that the lubricants are food grade. It is important also to know that they are suitable for the specific application and being used properly by the operators. Many food manufacturers expect their lubricant suppliers to not only provide a registered product, but also training support and a real business partnership that can ensure success in complex industry.

“When you look at the big picture, high quality food-grade lubricants often turn out to be very beneficial investments,” summarized Taco Mets, technical director at Van Meeuwen Lubrication and working group chairman (lubricants) for the non-profit European Hygienic Engineering and Design Group. “By using H1 registered lubricants, food producers have managed to reduce processing downtimes related to lubrication by up to 90%. The better your lubricants match with your applications and conditions, the less time and effort you’ll have to spend to keep your processes running smoothly.”

Finding an H1 Lubricant Supplier

Food processing managers should look for a lubricant supplier that has:

•Appropriate registrations or certifications. Most reputable suppliers have products backed by independent registrations such as H1 or ISO 21469. Registration can be verified at www.nsfwhitebook.org and www.nsf.org/certified-products-systems.

• Applications specialists with an understanding of HACCP and food safety principles.

• Understanding of the unique challenges in the food processing environment, as well as the technical requirements and specific risk-management responsibilities. This should include the types of products being made in the factory, such as those making a “free from” or vegan claim.

• Training support. Most reputable suppliers support their customers with workplace training, education and hands-on application support for the end user, which can be a significant benefit.

Claire Goring is supply chain and technical consulting manager at NSF International in the U.K. She has 20 years of experience in audit, compliance and technical management roles in many food sectors. Contact her at cgoring@nsf.org.