Performance without Compromise

Esters have become almost synonymous with high-performance formulations used in demanding environments where other base stocks would typically fail. And thanks to greater environmental awareness, increasingly strict regulations and the push toward more sustainable solutions, robust demand growth is expected in the years ahead.

Esters excel in terms of biodegradability and low toxicity and are commonplace in multiple end-use sectors including construction, marine, mining, power generation, forestry, agriculture and transportation. Indeed, these hugely versatile Group V base oils—a combination of carboxylic acids and alcohols—can be adapted to suit almost any application.

Yet despite their flexibility and high levels of performance, they do have their flaws, admits Arthur Coen, application manager for lubricants at leading oleochemical producer Oleon. For all their positive attributes, esters’ performance can be adversely impacted by hydrolysis, causing degradation of the lubricant as well as poor elastomer compatibility.

However, after several years in development, the Belgium-headquartered producer says it has been able to overcome these hurdles with a recent addition to its portfolio, Radialube 7253.

Oleon’s new product allows users to enjoy the flexibility and excellent levels of performance they require without compromise, says Coen.

“Typically, esters have an excellent viscosity and volatility profile, very high lubricity and a great temperature range—but esters tend to suffer from two specific pain points: poor hydrolytic stability and elastomer compatibility,” he says. “We have succeeded in mitigating the typical drawbacks associated with esters while keeping all of the benefits.”

Close collaboration between its two main business units has allowed it to develop an innovative fatty acid grade that overcomes both these issues, says Coen. Earlier this year, the business was also able to double the capacity of this new fatty acid, ensuring it could meet future demand growth for the unique ester.

Oleon specializes in natural, sustainable and responsible chemistries derived from renewable raw materials. Over the past six decades, it has developed a broad portfolio and is now recognized as one of the world’s leading producers of esters that can be used in environmentally acceptable lubricant (EAL) applications.

Its base oleochemicals division splits animal fats and vegetable oils into fatty acids and glycerins, with its derivatives business unit then taking these core components and combining them with alcohols, before converting them into natural esters.

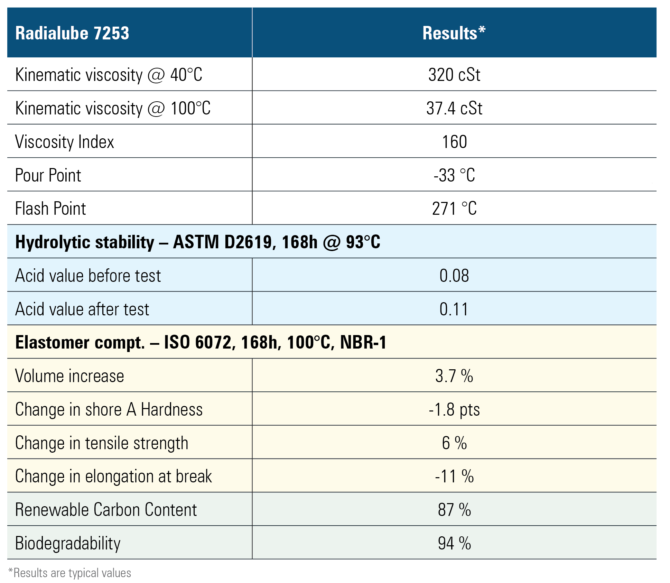

While Radialube 7253 offers the usual high levels of performance expected of a typical ester, it also guarantees minimal impact on elastomer compatibility for the end product, as well as improved hydrolytic stability.

Oleon first introduced this premium product in 2015, but continuous development has led to a breakthrough this past year in terms of oxidation stability and quality improvements, notes Coen.

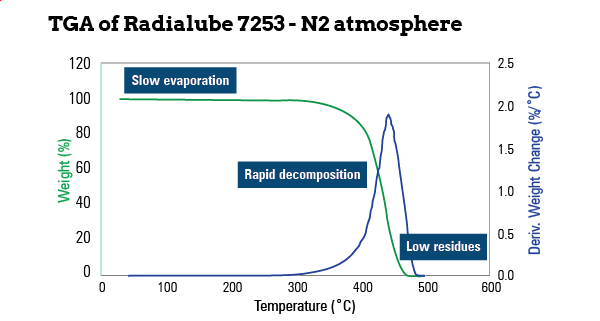

Customer feedback has so far been extremely positive, with many pointing to its strong performance in terms of thermal stability—a result of the special fatty acid and its branched structure. Tests have also demonstrated particularly good shear stability, as well as a lack of deposits, varnish or sludge.

“We have been really pleased to get some great feedback and are seeing good growth with this product range that is in line with expectations,” he says. “Oleon has developed a broad portfolio of specially designed EAL base oils and has many years of knowledge and experience. We recognize that sustainability has become a market requirement and will only become more and more important in the years ahead.”

The company currently has over 40 esters featured on the Lubricant Substance Classification (LuSC) list—globally recognized guidelines that identify products that stand out in terms of biodegradability, aquatic toxicity and renewability, and that offer minimal environmental impact.

Although Coen points out that Oleon does not directly make finished lubricants, the inclusion of its components on the LuSC list helps formulators meet the criteria required to attain EU Ecolabel certification—a program aimed at encouraging high environmental standards, CO2 reduction and the inclusion of renewable raw materials.

Oleon’s products are compliant with all recognized regulations and labeling systems worldwide.

“There has never been a bigger focus on life-cycle assessment and reducing your carbon footprint,” he says. “At Oleon, we are always looking for even better solutions. Radialube 7253 has been a natural progression for us. It was a very complicated process and has been incredibly difficult to get the balance right.”

“Biodegradability is achievable with many different base oils—but only with low viscous grades. The high viscosity is what makes these esters really stand out,” says Coen. “We needed that biodegradability so it could be used in EAL applications and wanted excellent hydrolytic stability, good pour points and a high flashpoint. This was something that wasn’t thought possible, but we’ve managed to do it. Achieving something like this takes a lot of time, effort and research.”

Sustainability is the cornerstone of Oleon’s strategy and the business remains firmly focused on innovation to ensure it is able to meet the unique requirements of its customers, insists Coen.

“The lubricants market is constantly looking towards more sustainable products, and Oleon is always thinking about how we can make our processes and products better,” he says.

“We’ve developed a broad portfolio of specially designed environmentally acceptable lubricants, but our business is always evolving, and we’re constantly working on making our esters even more sustainable and effective.”

Discover which Oleon products answer to your EAL needs at eal.oleon.com